When replacing exhaust manifold cats (this example covers the VW Golf manifold cat), Bosal recommends tightening the bolts sequentially and making sure they’re torqued to the VM specifications.

If this is not done correctly then problems can arise; often the flange has been tightened from one end sequentially to the other, allowing the flange to leak at one side.

If this is not done correctly then problems can arise; often the flange has been tightened from one end sequentially to the other, allowing the flange to leak at one side.

Unmetered air entering the exhaust system can cause many issues. The extra oxygen can ‘superheat’ the cat and melt the substrate, while the unmetered air will cause engine management issues (high Lambda readings at the tailpipe). The extra oxygen will be seen as a lean mixture and, as a result, the engine management will try and compensate by adding extra fuel.

This extra fuel can burn in the cat, causing melted substrates, and it can cause the precious metals in the washcoat of the cat to regress into the ceramic monolith. In the case of cats with metal monoliths the precious metals are simply blown through (and out) of the exhaust system, making the cat less efficient. This can happen in a very short time

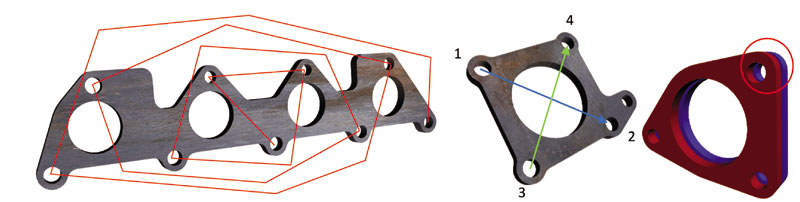

To avoid these issues Bosal recommends starting from the centre outwards. This can be done in two ways – either spirally or alternating – but always working from the centre outwards.

The tightening process – 5 simple steps

The tightening process – 5 simple steps

- All nuts should be done up (in sequence) finger tight; at this point you can check to see that your gaskets are properly positioned.

- Tighten (in sequence) to a quarter of the manufactures spec.

- Tighten (in sequence) to three quarters of the manufactures spec.

- Tighten (in sequence) to full manufactures spec.

- When the cat has been run and preconditioned and allowed to cool down, recheck and tighten (in sequence), if needed.

You can use this method to tighten any number of holes – from two or more. Just spending the small amount of extra time and care can avoid customer disappointment, rework complications, extra cost and damage to your reputation.

Freelander made easy

The Land Rover Freelander is well known for suffering with emissions issues that are commonly as a result of the cat flanges not being tightened evenly. The top bolt hole is awkward to reach because it’s near the prop shaft and is usually the last nut/bolt to be done up. Because the bottom two bolts tend to get tightened to their maximum with an air gun, while the top belt is tightened by hand with two spanners, air leaks can occur which leaves a black carbon leak stain on the flanges and gaskets. These can be avoided by sticking to the method described in this article.