Make sure a damaged flywheel doesn’t result in starter motor failure, as Autoelectro explains

A DMF (Dual Mass Flywheel) is designed to absorb torsional vibration which is produced by the engine and other components. Any abnormal increase in these vibration levels, however, can drastically reduce the life of the flywheel and cause it to break up, producing metal filings in dust-like particles.

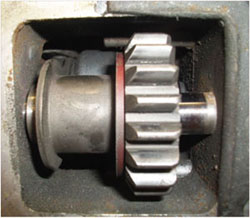

These metal filings are then attracted to the starter motor’s magnets within the yolk assembly and can also cause contamination on the gear shaft. This, in turn, leads to the roller bearing becoming dry and can also result in the gear sticking on the shaft, causing excessive noise during operation.

These metal filings are then attracted to the starter motor’s magnets within the yolk assembly and can also cause contamination on the gear shaft. This, in turn, leads to the roller bearing becoming dry and can also result in the gear sticking on the shaft, causing excessive noise during operation.

Overcoming the problem

Carrying out the appropriate checks on the DMF can reduce the risk of premature starter motor failure and avoid any other associated issues within the flywheel system.

It is also recommended to ensure the gearbox housing is thoroughly cleaned out before fitment of the starter motor to reduce the risk of contamination, even if remedial work has been carried out i.e. replacement of DMF or a conversion to a single mass flywheel. Failure to thoroughly clean the gearbox housing will still result in existing dust entering the starter motor, leading to premature failure.

What factors can cause abnormal flywheel wear?

What factors can cause abnormal flywheel wear?

■ Engine misfires.

■ Starting issues.

■ Slow/lazy cranking.

■ Towing excessive loads.

■ Low cylinder compression.

■ Excessive use of the clutch i.e. clutch control on inclines.

■ Driving in the wrong gear to try and save fuel.

How to inspect the flywheel for signs of excessive wear

■ Inspect the friction face for signs of excessive heat, scoring or damage.

■ Inspect for excessive loss of grease (DMFs are packed with grease – if there is not much (or none) there it will suggest excessive heat).

■ Check for any visible damage to the ring gear or bearing.