Febi takes us through the rear suspension on the trusty Ford Mondeo.

The Ford Mondeo model produced from 2007 to 2014 was the fourth incarnation of this family favourite. It was renowned for having good load-carrying capabilities, which also made it popular with many company car drivers and the emergency services. This model shares many of its platform similarities with the Galaxy and S-Max, and also some Volvo models – including the design of the vehicles’ suspension system and the components used.

This Mondeo was equipped with an independent multilink rear suspension system which was available in standard, sports and heavy duty versions – with or without self-levelling dampers or electronic control. However, all other suspension parts were fundamentally the same. This was all subject to each model specification (Fig.1).

The many suspension bushes, bearings and joints that make up this vehicle’s suspension work together in unison to provide safe handling characteristics and comfort for the driver, passengers and any load the vehicle is carrying. Through time these can become worn or damaged; eventually losing their effectiveness, which can then be felt, seen and heard. Frequent ‘knocking’ or creaking noises can be heard and the steering can become vague, causing uneven tyre wear and giving poor contact with the surface of the road, which can affect the vehicle’s braking ability.

The rear trailing arm bushes are a common component of this system and can deteriorate over time. The rubber becomes torn and the outer casing corrodes, giving the vehicle a ‘slumped’ look; causing the suspension to become out of alignment and operate incorrectly (Fig.2).

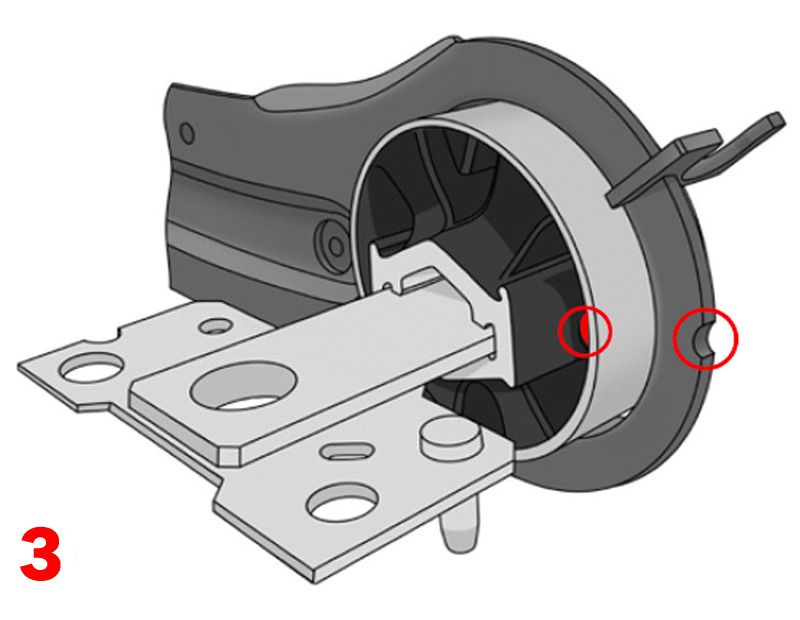

These bushes can be replaced separately, which saves replacing the whole trailing arm. This can be executed by using a special tool to push the old bush from the arm and pull the new one in; not forgetting firstly to align the bush – with the alignment points on the bush – with the arm (Fig.3).

This is imperative for the correct operation of the bushes. The new febi bushes’ outer metal casing has a leading edge for ease of fitment. Being made from vulcanised natural rubber gives it excellent mechanical properties and hardness – ensuring a long service life.

One of the challenges when repairing a vehicle’s suspension system is being able to remove any of the bolts or fixings (which are ‘securing’ the worn parts) that are being replaced. The original bolts become corroded and weakened over time, having endured constant attrition from the elements. Many different methods may be required to do this – including the use of penetrating fluid, heat or the fixings being cut to remove them. This renders the original bolts unfit for purpose, and is often overlooked during this type of repair. febi offers a solution to this issue by providing a repair kit with the new bolts included. As an example, axle beam mounting kit 43403 comes complete with bushes for both sides of the vehicle as well as bolts. For a more complete repair febi ProKit, 46000 cross strut kit comes complete with bushes, bolts and suspension links.

The bolts provided have high tensile strength for securing safety-critical components, with excellent clamping force and an anticorrosion coating for longer service life. These bolts also have leading threads for easy fitment and a thread-lock treatment to resist loosening during operation.