The Vauxhall Zafira has been on our roads for many years, and is a firm favourite with families and taxi drivers alike. The result of this popularity means that this model has sold over 370,000 vehicles in the UK and, as the average mileage of these vehicles increases, we are starting to see more and more in the aftermarket.

A clutch replacement on the Zafira is really straightforward and with the guidance of LuK the whole process will become even easier. Nothing out of the ordinary is needed to complete the job, the only special tools required are an engine cradle, a transmission jack and a long axle stand. A two-post ramp was used in this example, however a four-post ramp may not provide enough clearance.

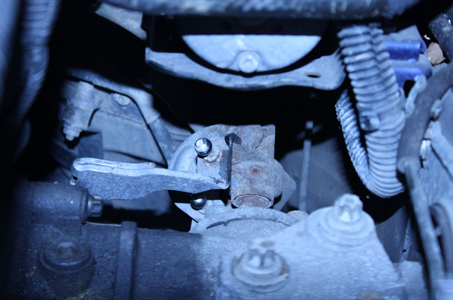

Before starting work, if the vehicle has alloy wheels make sure you have the locking wheel nut. Locate and undo the steering column coupling (pictured below) in the driver’s foot well. Open the bonnet, disconnect the battery terminals and remove the battery clamp. Lift out the battery and the plastic surround and undo the bolts securing the metal battery tray. To provide enough space to remove the tray, undo the single screw securing the ECU mounting and move it to one side.

Release the electrical harness attached to the battery tray and lift the tray out. Disconnect the slave cylinder connection at the top of the gearbox (pictured below) and use a blanking plug to prevent leakage.

Release the gear selector cables from the transmission by carefully levering them off the mechanism (pictured below).

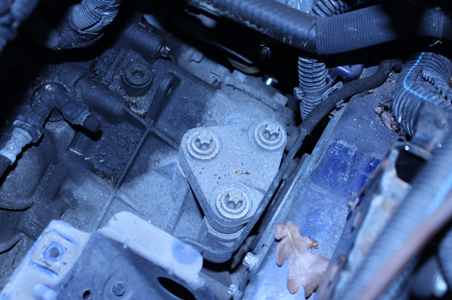

Release the cables from the support bracket and remove the accessible upper bell housing bolts. Using the engine cradle, support the engine and gearbox and remove the gearbox mounting (pictured below).

Raise the vehicle and remove the N/S front road wheel and the plastic engine under-tray. Disconnect the reverse light switch and release the clips attaching the front bumper to the sub-frame (pictured below).

Undo the bolt securing the N/S lower suspension arm to the lower ball joint (pictured below) and release it.

Undo the hub nut on the N/S side and release the drive shaft from the hub. Drain the gearbox oil and remove the short driveshaft from the gearbox. Unbolt the front engine mounting and support the weight of the radiator by using a pair of cable ties on the front panel. Unbolt and remove both rear sub-frame support plates and slacken the four large bolts (pictured below) securing the subframe.

Undo the rear gearbox mount and the bolt securing the coolant pipe to the front of the gearbox casing.

Undo and lower the exhaust downpipe for better access and release the power steering harness attached to the sub-frame. Remove the reverse light switch harness attached to the gearbox casing and, with support, lower the sub-frame down enough for the gearbox to be removed. Finally remove all the remaining bell housing bolts and remove the gearbox.

With the clutch removed, check the Dual Mass Flywheel (DMF) for signs of heat stress and evidence of grease loss. The DMF should also be tested for ‘freeplay’ and ‘rock’ between the primary and secondary masses (LuK tool number 400 0080 10 is specifically designed for this purpose on all LuK manufactured DMFs). Full instructions and tolerance data for all LuK DMFs are contained on a CD which comes with this special tool.

Clean the first motion shaft splines and any debris from the bell housing (especially important when a release bearing has failed). Put a small dab of high melting point grease (not a copper-based product) on the first motion shaft splines and make sure the new driven plate slides freely back and forth.

This not only spreads the grease evenly but also makes sure you have the correct kit. Wipe any excess grease off the shaft and driven plate hub. Using a universal alignment tool and checking the driven plate is the correct way round (note “Getriebe Seite” is German for “Gearbox Side”) the clutch can be bolted to the flywheel evenly and sequentially.

Before fitting the gearbox, make sure the locating dowels are in place and not damaged. Refit any that have become dislodged and refit the gearbox. Make sure the gearbox bell housing bolts are secured before lowering the jack. Refitting is the reverse of the removal.