For auto locksmiths working with key cutting technology, systems must deliver consistent cutting and tracing results without errors. 3D Group explains why regular recalibration should be on your agenda.

Effective machine calibration should be viewed as the foundation of machine maintenance. It’s the first step to producing reliable customer results and ensuring device performance. This is the reason auto locksmiths should be paying close attention their recalibration schedules.

Calibration is used to establish a reference point that assists instruments in producing accurate results. All instruments of measurement, whatever they measure, require calibration. Take, for example, your kitchen scales at home – these should be calibrated too. Without calibration, we cannot guarantee that the results given will be accurate. This could result in significant problems for not only you but also for your customer.

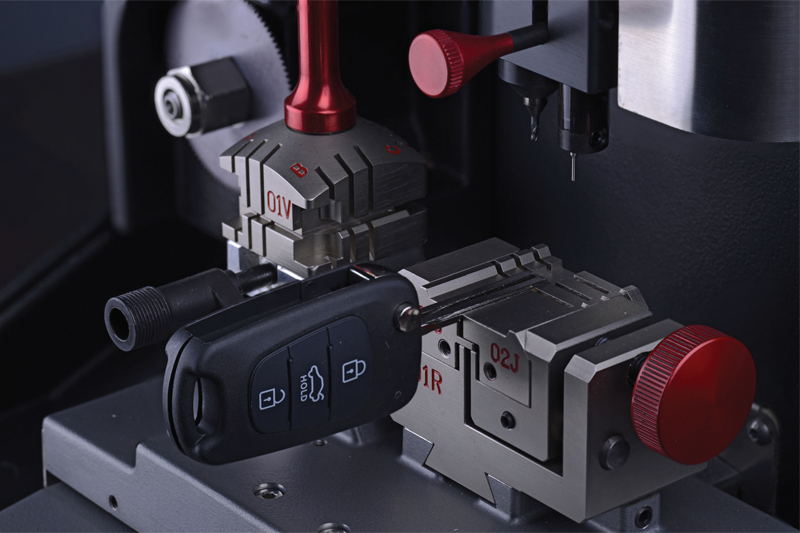

Key machine accuracy

The accuracy of devices such as key cutting machines can degrade over time and is typically caused by normal wear and tear. However, changes in accuracy can also be caused by electric or mechanical shock or a hazardous manufacturing environment, such as one containing oils, metal shavings etc. Therefore, depending on the type of key cutting machine and the environment in which it is being used, the time it takes before it becomes inaccurate will vary. Devices such as the Dolphin, which many mobile auto locksmiths use in their van, could require recalibrating more often. Due to the movement of the vehicle, the key cutting machine may experience changes in its calibration.

Without proper calibration a key blank could potentially not be cut to the required specifications, causing a key that will not fit in the lock or function correctly in the ignition. Spending five minutes recalibrating your key cutting machine could save you the time and cost of having to recut a customer’s key.

The bottom line is that calibration improves the accuracy of the device, and accurate measuring enhances the quality of the product.

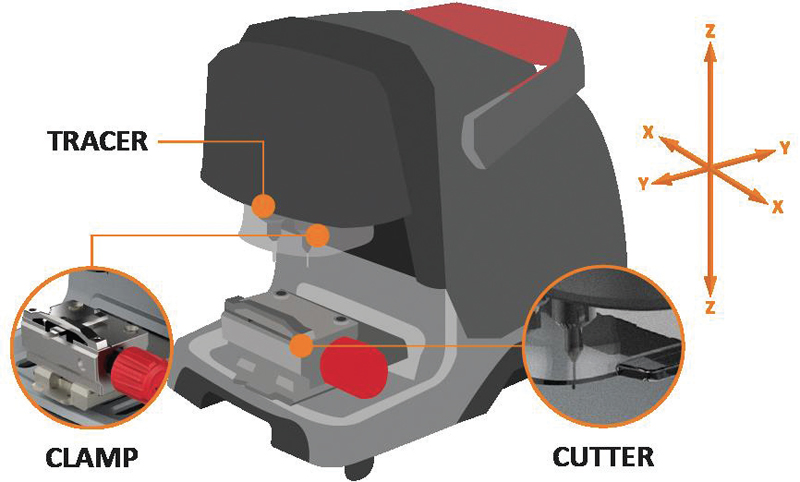

As there are three axes for key cutting and tracing (as shown below in the diagram), all three axes must be calibrated accurately, otherwise it may result in a key that is not cut to specification. Without proper calibration, key bittings will not be cut accurately, resulting in a faulty product that may need to be remade.

How often should you recalibrate?

Auto locksmiths should calibrate a key cutting machine in line with the following criteria:

- According to the recommendation of the manufacturer

- After any mechanical or electrical shock

- Periodically (annually, quarterly, monthly)

The technicians at 3D Group recalibrate their key cutting machines daily to ensure accurate key cutting at all times; as the key cutting machines are used every day, they need calibrating more often.

One thing you need to consider is whether you work with a manual or automatic machine. A manual key cutting machine requires more regular calibration, possibly every one to two weeks because they rely on human calculation, such as the Xhorse Dolphin.

Newer, automatic machines such as the Xhorse Condor will only need calibration when the cutter or tracer has been changed.

Avoiding extra costs

Cutting keys can become a costly experience if defects occur, for example, minor measurement errors when tracing a key. When these errors occur, you must stop the process, source new materials, and restart, causing you and your customer delays. This is expensive in both time and resources, or worse yet, defective parts could be delivered to your client. We all know that word of mouth is king and maintaining customer satisfaction is crucial to business success. Unfortunately, these errors when cutting keys cause less than desirable feedback to be left about you and your service.

Keeping your machinery up to scratch with proper calibration will help keep these errors from happening and provide your customer with a service they will be happy with.

Do it yourself

As the owner of the machine, you will be able to complete the recalibration yourself, your device will come with instructions, and there is plenty of assistance online. What’s more, if you purchased your tool from a reputable supplier like 3D Group, the tool should come with all the tools necessary for the recalibration of your key cutting machine.