KTS Diagnostic Made ‘ESI’ from Robert Bosch

This regular series of technical articles from Bosch focuses on how to get the best out of its ESI[tronic] 2.0 software, which is used in conjunction with the KTS range of diagnostic tools for vehicle fault diagnosis and service function procedures.

In this month’s issue we’re going to introduce you to the added benefit of vehicle diagnosis, using the built-inmulti-meter or oscilloscope functions included in the KTS Vehicle Communication Interface (VCI), in conjunction with the serial diagnostic capabilities of the Bosch ESI 2.0 program.

Many technicians consider a graphing multi-meter or oscilloscope an extra investment, along with all of the other equipment required to effectively work on modern cars today. The good news is that if you own a Bosch KTS 540, then it already has a single channel multi-meter included and our flagship tool – the KTS 570 – features a two channel multi-meter or oscilloscope which is all ready for you to use (see Fig 1).

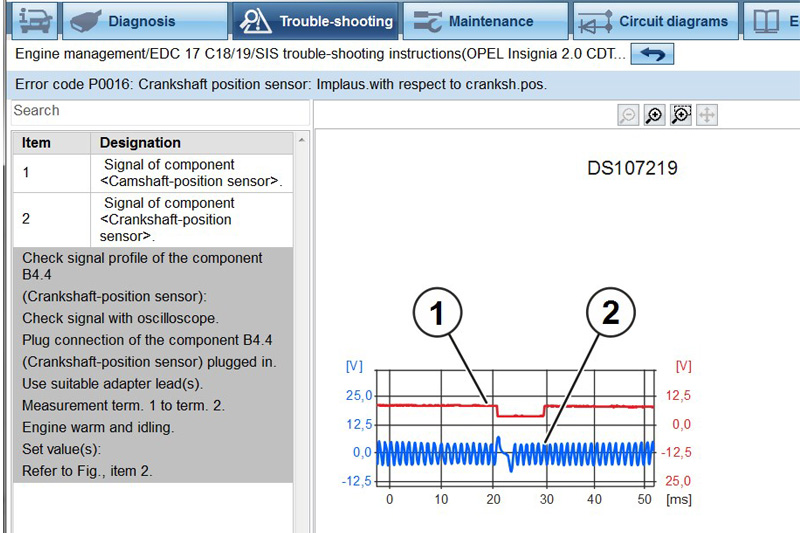

The kit contains high quality colour-coded test cables and probes, which use standard 4mm ‘banana’ type connectors. As we all know, often a Diagnostic Trouble Code (DTC) will only give a guide to the general area of a system that is suspected to be faulty or out of range. Once a DTC is read from the error memory of a control unit, a good fault finding process is required to test the suspected component and its associated electrical circuit. In Bosch ESI 2.0, there are many Service Information System (SIS) repair instructions linked to an error memory code that will suggest a direct measurement needs to be made of the voltage supply, earth path, or signal/command wire or component resistance in the system (see Fig 2).

These values can be tested using the Bosch KTS multi-meter or oscilloscope, along with ‘guided’ fault finding instructions and technical data through ESI 2.0. This will give you confidence in your results and should certainly lead to an improved first time fix rate of your customers’ vehicles.

For this article, we’ll concentrate on the multi-meter and scope functions of the KTS 570. Please remember that if you have a KTS 540, there is no scope capability built into the VCI. For technicians that use a separate oscilloscope – such as the Bosch FSA 500 or FSA 720/740 series – then the KTS 540 is

perfectly suitable for multi-meter use.

The KTS multi-meter functions

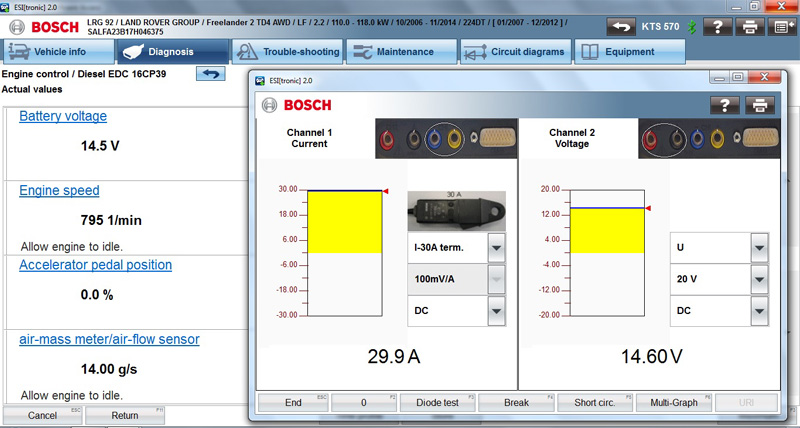

We’ll first take a look at the Bosch KTS multi-meter functions that can be used alongside the ESI 2.0 vehicle diagnostic program. When the multi-meter is accessed via the main menu (see Fig 3) a new window will appear on-screen with the multi-meter display and measurement selection options.

Now you can overlay the multi-meter results screen over ESI 2.0 and see the serial diagnostic data and direct measurements side by side (see Fig 4).

The test results will be wirelessly displayed on your PC screen, with the measurements taken by the probes attached to the KTS VCI which is connected to the vehicle (see Fig 5).

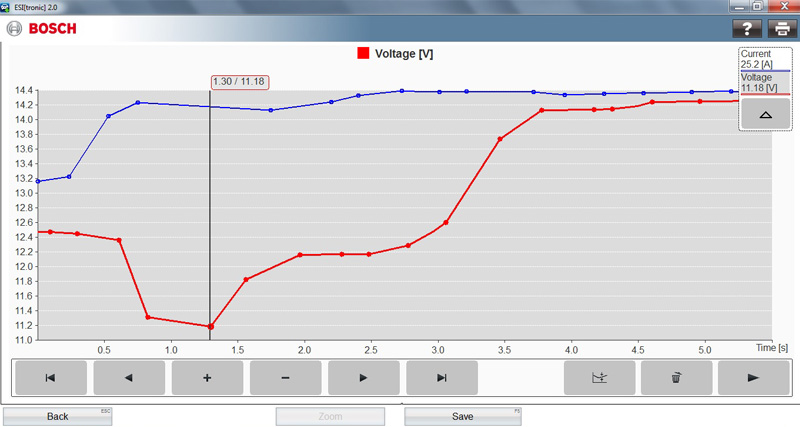

The readings can be shown in a numerical form, with a useful bar graph, or in a graphing trace format, with up to a minute across the screen. This gives the user more convenience, depending on the measurements being taken. Another great feature is that, just like the actual value time profile display in ESI 2.0, the multi-meter graph can be paused, reviewed, saved and printed (if necessary) for reference (see Fig 6), showing battery voltage and current upon starting the engine.

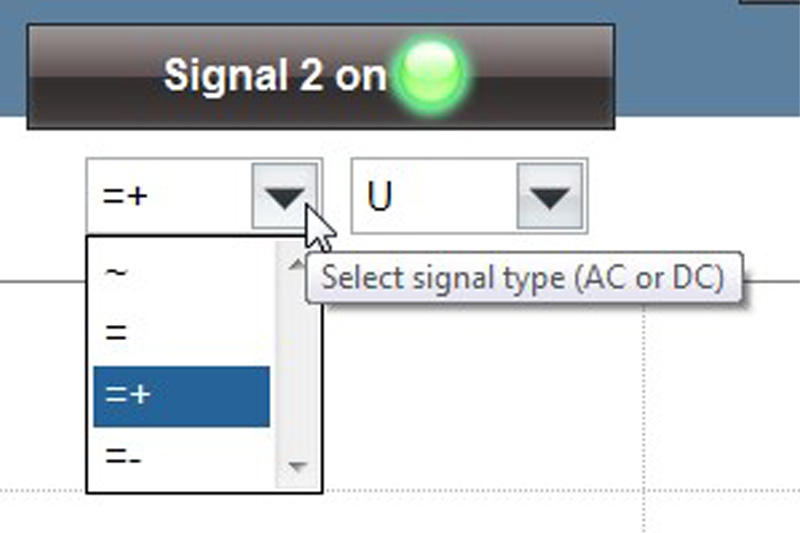

For voltage and current readings, we have the choice of DC, AC or EFF (root mean square) settings on both channels and resistance measuring up to 1 M Ω on channel 1. You can connect a Bosch amps clamp with adaptor for non-intrusive current measurements to be displayed on screen. A really useful additional feature of the KTS multi-meter is the circuit break and short circuit function, which you can configure to emit an audible warning signal when you conduct a wiggle test on the suspect harness to help you find wiring faults along a loom.

The KTS oscilloscope

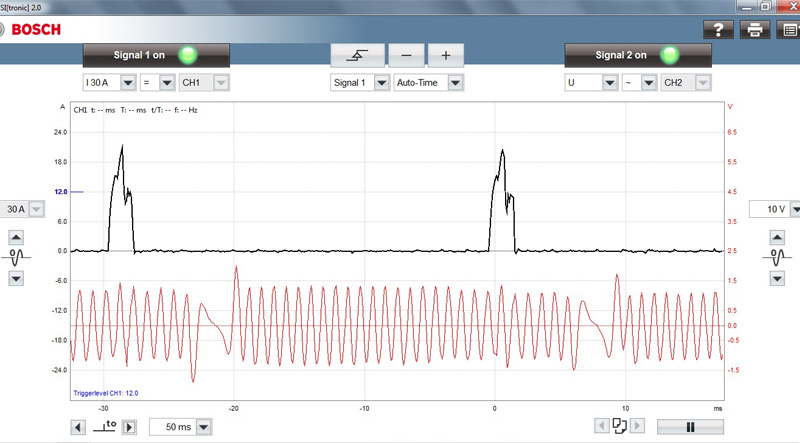

Now we’ll look at our Bosch KTS 570 two channel oscilloscope functions that can be used for even greater in-depth testing of electrical systems and components. The beauty of using an oscilloscope is that it opens up a whole new dimension of system diagnosis by presenting to the user an accurate graphical representation of voltage over time. This means you can see in detail what is actually happening in an electrical circuit in real time. Fig 7 shows a PD injector and crankshaft sensor signal.

Opened from the main menu, the oscilloscope screen can be viewed alongside the ESI 2.0 program and offers many customisable settings that enable you to effectively capture and display the test results you need. Trigger points can be set to be sure that signal recording starts where you want it to and waveform display options can be used to get the best results. There are too many options to describe them all here, but if you hover your cursor over any icon or soft key a ‘tool tip’ pops up with a description (see Fig 8).

The time base for both channels can be set between 50 micro seconds and 1 second across the screen. The safe continuous input voltage to the VCI is a maximum of 60V and the scale of measurement in voltage can display from 100mV (10mV/division) up to 200V (20V/div) up the screen. In the current

measurement, the amps scale can be selected between 30A and 1,000A. If you pause the scope recording the buffer memory holds the previous 25 screen captures, which can be scrolled through and reviewed. This is essential if you’re searching for an intermittent fault.

If only a single channel measurement is required then the blue and yellow cables can be used for potential free testing when the black earth cable is connected to channel two. This set-up can be particularly useful for testing both signal wires of an inductive speed sensor, for example.

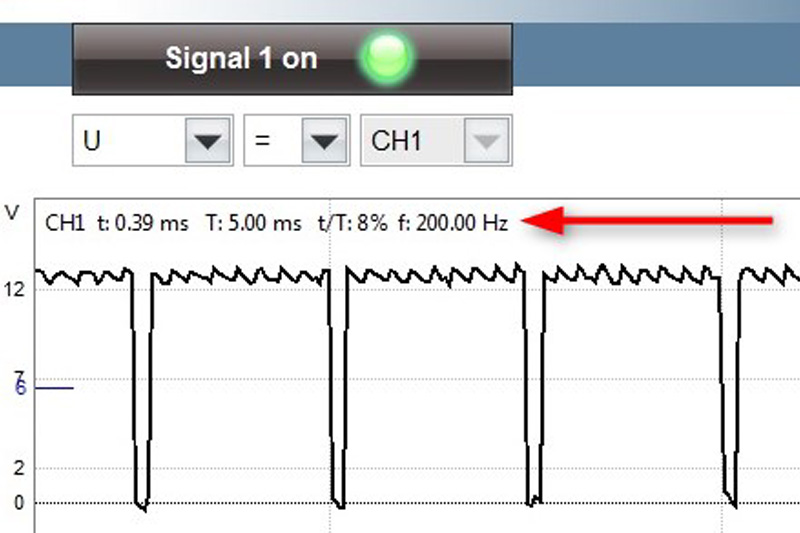

When a signal is being collected, the ESI 2.0 oscilloscope software automatically starts to calculate the specific signal on/off times and frequency of the waveform, if it is a repeated signal such as a Pulse Width Modulated (PWM) duty cycle. This is really useful if you’re checking the command signal

to a component, such as a radiator fan control module (as shown in Fig 9).

Another great feature of the scope is the ability to choose the channel option for signal acquisition via the coloured test cables connected to the channel inputs of the VCI.

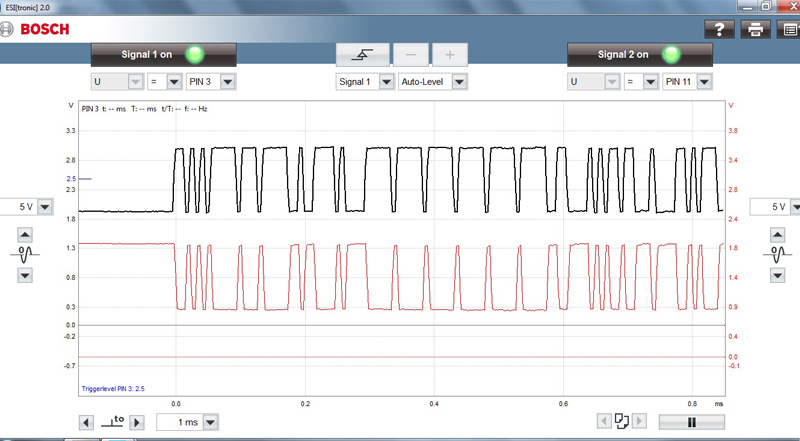

Additionally, you can switch to the ‘PIN’ input option, where the signal will be taken rom the communication pins of the 16 pin OBD socket that will already be connected to the car. The earth pins 4 and 5 and power supply pin 16 are not available to scope this way but any of the other pins are (depending on the vehicle configuration). For example, a single wire ‘K’ line on pin 7 or a CAN Bus

signal on the traditional pins of 3 & 11 or 6 & 14 could be ‘internally’ tested (as seen in Fig 10). This can be a very quick and easy way to investigate if any control unit communication problems occur.

What are you waiting for?

If you use a Bosch KTS 570 and haven’t tried oscilloscope testing, then we highly recommend that you give it go. This article is intended as a brief overview of the multimeter and scope capabilities within Bosch KTS as, in reality, we could write a whole book on the subject!

The Bosch Automotive training course ‘WTE1 operation of Bosch KTS’ covers an introduction to the in-built multi-meter and scope functions and is a great way to get some experience under your belt. For those looking to step things up a level, the Bosch ‘VSTD9 Oscilloscope Operation and Signal Test Methods’ training course goes into greater detail of oscilloscope testing and waveform analysis.