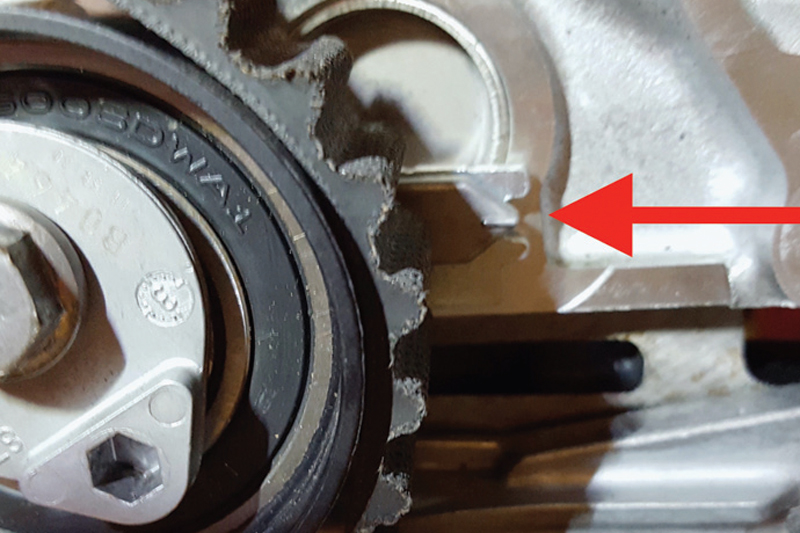

Gates explains how failure to loosen the camshaft sprocket when setting belt tension can lead to disastrous consequences for the engine.

For most of the latest models of camshaft sprocket, the sprocket must be loosened when the timing belt tension is being set – you are advised to check the vehicle manufacturer’s fitting instructions. If loosening the sprocket is required, the online fitting instructions for the Gates PowerGrip Kit will make this clear.

Loosening the camshaft sprocket ensures that the engine is aligned at Top Dead Centre (TDC). This is an important part of the procedure and ensures that the installer can achieve the correct load distribution when setting the tension for the new timing belt. Failure to loosen the camshaft sprocket when it is part of the prescribed installation procedure will lead to comebacks.

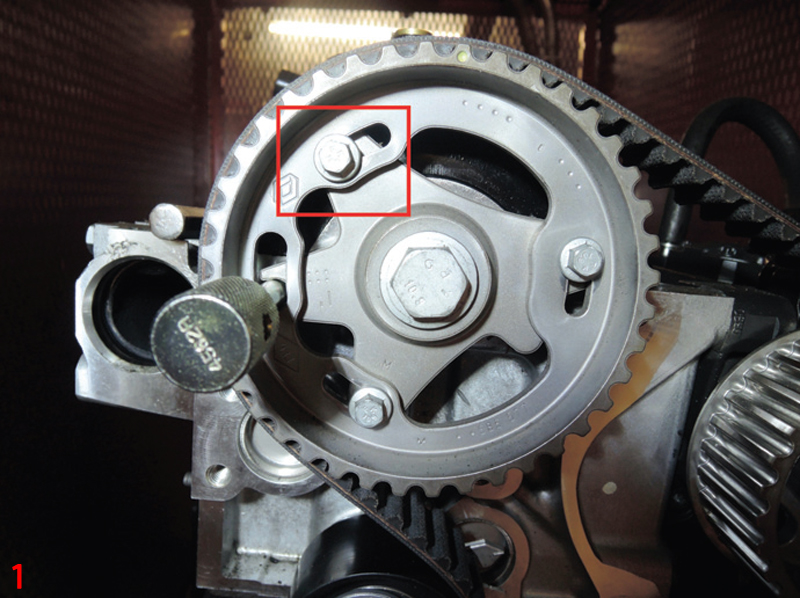

Correct procedure – loosened

When the camshaft sprocket or pulley is loosened, the timing belt can run into the gearing of the camshaft pulley while the tension is set. The camshaft pulley has room to move because the bolt can slide along the slot (Fig 1). This enables tension to be transmitted to the loaded side (or tight side) of the drive.

Fig 1 shows the position of the bolt when the camshaft sprocket is loose, before the timing belt tension is set. Note that a camshaft locking tool is already in place.

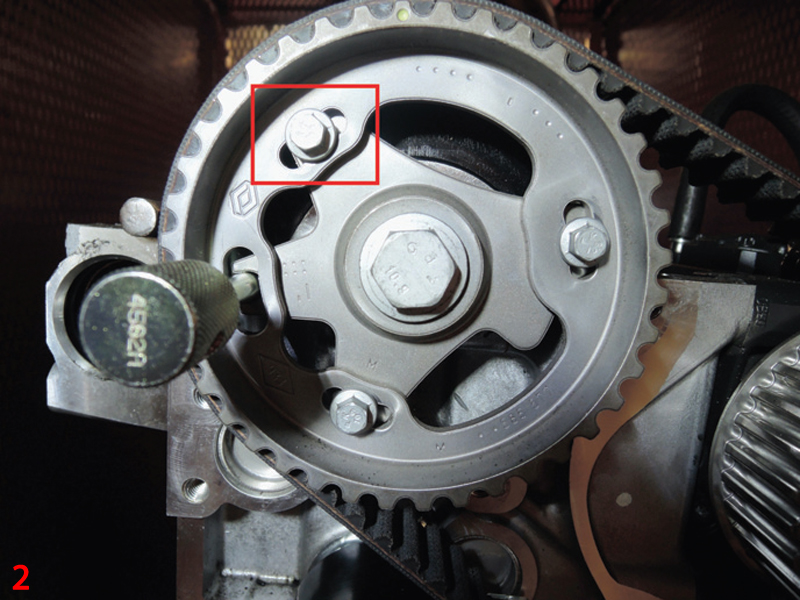

Fig 2 shows what happens to the bolt as the tension is set. It moves to a new position, but the locking tool ensures that the engine remains in TDC.

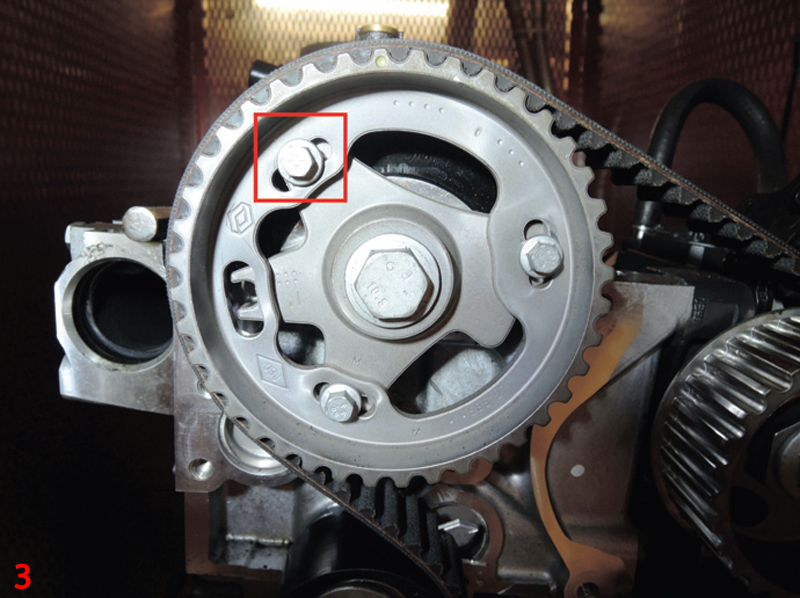

Incorrect procedure – not loosened

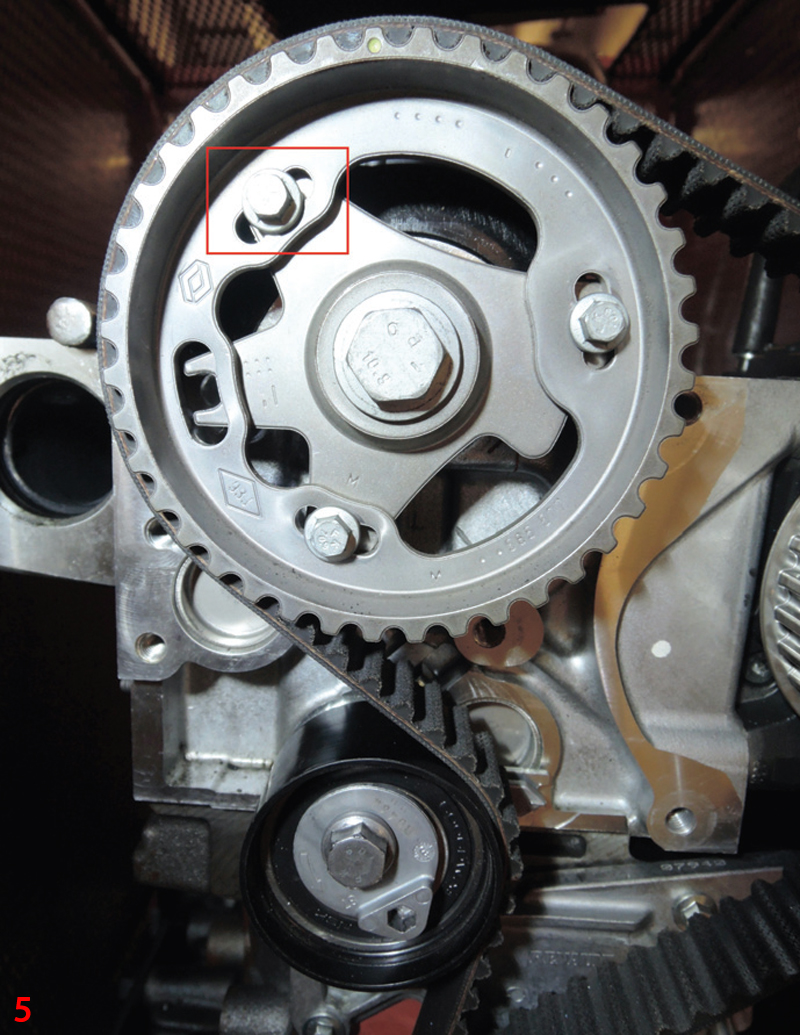

Fig 3 shows a camshaft sprocket that has not been loosened before the tension is set. Note the position of the bolt in the slot – no locking tool is in place.

As the camshaft sprocket remains fixed, the timing belt cannot run into the gearing as it should. It will only receive tension on the slack side of the drive, and, at that moment, the loaded side of the drive will not have the correct tension. Turning the engine clockwise at the crankshaft pulley means that first the belt will be tensioned, then the camshaft pulley will move. From that moment on, the engine position (TDC) is not exact. This leads to a load in the drive that is much higher than normal, while the engine is running.

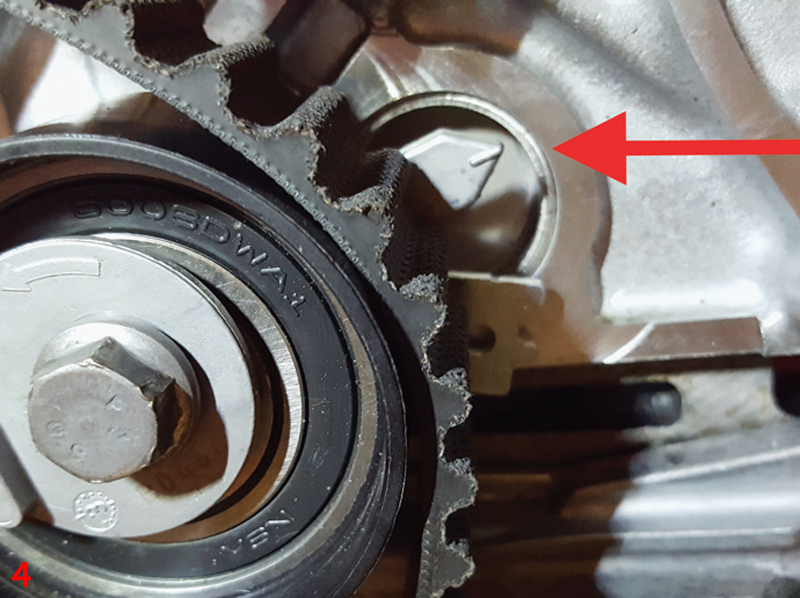

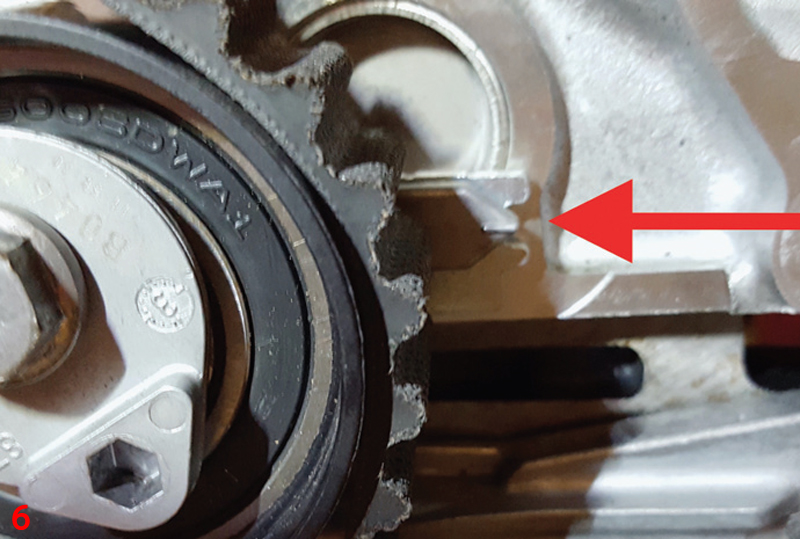

Moreover, because the camshaft sprocket is fixed and the timing belt cannot run into the gearing as it should, the pointer reaches the central position earlier in the tension setting process (Fig 4).

Fig 5 shows no change in the position of the camshaft bolt in the slotted hole after the timing belt tension has been set.

Fig 6 shows the position of the pointer at the end of the tension setting procedure.

Consequences for drive systems

If operating conditions are adversely changed, the operational lifetime of the belt inevitably decreases. Eventual consequences often also include uneven tension, tensioner failure, and water pump failure.

Premature drive system failure is inevitable in each case, and engine damage is possible. Furthermore, in many cases where a loosening of the camshaft sprocket has been specified, but did not take place, the tensioners do not move far enough into the drive. They are set, therefore, in geometrically incorrect positions on the engine blocks. This changes the alignment of the timing belt and optimal control can no longer be guaranteed, also making premature drive system failure inevitable.

If the engine is not set at TDC from the outset, higher loads are generated in the drive system, once again, causing premature drive system failure and potentially catastrophic engine damage – an expensive and unnecessary error.

Note – For drives with non-round pulleys, failure to loosen the camshaft sprocket when specified can lead to even further complications. The pulleys have to work in perfect unison, otherwise extreme loads are generated.