How to ensure trouble-free installation and performance.

Miten Parikh, Product General Manager, Comline shares some insight into one of the aftermarket’s most popular replacement filters. As a proud British brand with an established filter pedigree spanning almost quarter of a century, we’re in a great position to offer technicians valuable technical and installation advice relating to filters.

Comline EFF147 Fuel Filter

Selected OE references:

BMW – 13 32 7 804 958, Citroen – 1901

78, Fiat – 9401901788, Ford – 1232325,

Peugeot – 1901-67, Volvo – 30750085

Some aftermarket variants of this filter are prone to common faults and fitment challenges that can result in reliability issues. To combat such problems Comline has developed a number of important features into its EFF147 filter that are designed to deliver trouble-free installation and performance.

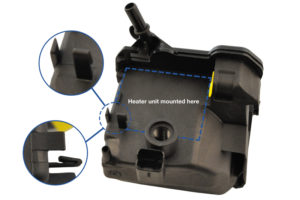

Heater unit installation

One of the most widespread faults with this type of filter is an issue with the mounting of the heater unit. Some examples of this filter fail to lock the heater unit securely in position, resulting in leakage due to an inadequate seal between the heater unit and filter. Aware of such issues, Comline has adopted a dual-clip design on its EFF147 filter which is designed to precisely locate the position of the heater unit for a solid, reliable seal.

Heater unit leakage

When replacing the filter it is an essential requirement to replace the O-rings on the associated heater unit. Failure to do so can also result in an inadequate seal between the heater unit and filter which, again, can cause leakage. For added convenience and simple, effective fitment Comline provides three replacement heater unit O-rings with each EFF147 filter.

Water level sensor installation

This particular filter carries a port for fitting a water level sensor, but it’s a feature that can cause some concern and confusion among technicians. The first point to note is that a water level sensor isn’t required on all vehicles and, in such cases, the port would simply remain unused.

In cases where the water level sensor is required, the actual fitting process is very simple with the sensor simply screwing into the port. There is, however, considerable resistance when tightening the sensor, followed by a very discernible ‘crack’. This can cause concern for the technician but both the resistance and the subsequent noise are absolutely by design.

In simple terms, as the water sensor screws into position, the head of the sensor actually breaks through

the dividing wall of the filter, putting the sensor in direct contact with the part of the filter where water

accumulates. The piece of the dividing wall that breaks as part of this operation does not in any way affect the performance or functionality of the filter.

Bleed/drain valve

Care should be taken to correctly drain water and bleed the filter to prevent a vacuum forming which would prevent fuel flow. For correct installation the bleed/drain valve on Comline EFF147 should be

unscrewed after filter installation and immediately closed as soon as fuel begins to flow. To ensure the correct procedure is followed, Comline provides full fitting instructions in the box with each of its

EFF147 filters.

Inadequate valve designs on certain variants of this filter can hamper the bleeding process and/or result in leakage. Comline EFF147 features a single, dual-purpose bleed/drain valve, manufactured with high-quality PP materials to prevent damage or twisting during valve operation.

In addition, the valve screw on Comline EFF147 can’t be fully unscrewed and removed from the filter. This feature not only reduces the likelihood of crossthreading the valve screw but also negates the possibility of losing a critical component during filter installation.