The Mazda 3 was introduced in 2003 to replace the aging 323. Over the years it has forged itself a reputation for high reliability and quality and has now sold over 77,000 models in the UK. Now, as the manufacturer’s warranty is expiring, we are starting to see more and more coming into the aftermarket.

Premature damage

In this article we are going to look at how to replace the front wheel bearing on the Mazda 3 and give you some handy hints and tips to help you on your way. The type of bearing used on the Mazda can be a little tricky to fit because it has to be pressed into the hub and during this process, if done incorrectly, you can damage the bearing prematurely.

Firstly check to see if the vehicle has alloy wheels fitted, if it has it may be fitted with anti-theft bolts so you’ll need to find the key. Raise the vehicle on a ramp (although the job could be done on the ground if necessary) and remove the wheel on the relevant side. When possible we recommend that you replace bearings in pairs, as chances are the bearing on the opposite side could be just as worn as the one you are replacing.

Undo the large hub nut securing the driveshaft and release the shaft from the hub. Undo the two bolts (pictured below) securing the calliper to the hub, remove the assembly and secure it out of the way.

Remove the brake disc and disconnect the ABS connector (pictured below).

Undo the lower ball joint bolt (pictured below) and release the lower arm from the hub.

Undo the nut (pictured below) securing the steering rack to the hub and release it.

Undo the bolt securing the hub to the suspension strut (pictured below) and release it from the strut.

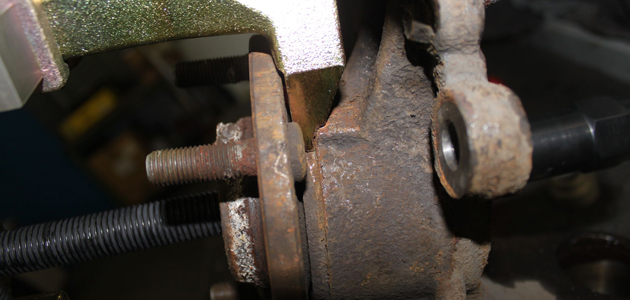

With the hub released use a press or a puller (pictured below) to remove the flange from the hub assembly.

Remove the large circlip (pictured below) retaining the bearing into the hub and push out the bearing assembly from inside the hub.

Depending on how the bearing separates you may need to extract the inner race from the flange; a puller was used in this example to remove the race from the flange.

Check the hub

Once the bearing components have all been removed, take the time to check that the hub profile is perfectly round and not damaged. The outer race of a bearing will always take the shape of the hub its being pressed into, so if the hub has been damaged and is not perfectly round this could prematurely wear the bearing over time.

This particular bearing comes with an ABS encoder ring on one side so you need to make sure you are pressing the bearing in the right way round, otherwise the encoder side of the bearing will be facing the wrong side. The seals on an FAG bearing are normally colour coded – black is the encoder side – however if you are unsure you can always use an encoder card to check.

Press on the outer race

When you fit the bearing into the hub make sure you press on the outer race. By doing this you ensure that the pressing force is not transmitted through the balls or rollers, but only through the outer race. The same applies when pressing the flange into the bearing. Ensure no force is transmitted through the bearing by supporting the bearing on the inner race and pressing on the flange directly. Fitment of the remainder is the reverse of the removal.

Finally its worth pointing out that the clamp load is essential on these types of bearings, so make sure you use a torque wrench when tightening the hub nut or bolt. Failure to do this could lead to premature failure of the new bearing.

Find out how to replace the front wheel bearing on a ‘next generation’ Ford Transit by clicking here