When examining a multi-ribbed drive belt, it is important to be aware that changes to the materials used in its construction mean that some of the visible wear indicators that could be applied to belts of the past are no longer applicable.

For example, experienced drive belt installers will recall some of the more common wear characteristics of the Auxiliary Drive Belt System (ABDS) belts made using Neoprene. Designed with a life expectancy of around 50 to 60,000 miles, as the end of their operational life approached, wear became obvious. This included:

- Cracks in the belt

- Missing chunks of material

- Rib separation

These visible signs helped technicians to confirm the need for belt replacement.

Belts made from EPDM

These days, multi-ribbed belts are commonly made from a quite different material known as EPDM. These belts are stronger and designed for much higher mileages, but the material does not crack with age. They are still subject to strain, stress and wear yet the visible evidence is not so obvious.

Concerned that technicians should be better equipped to identify the signs of wear to multi-ribbed belts and pulleys, when Gates introduced its new Micro-V Horizon belt (of which the entire range is made from EPDM see image below) at the end of 2012, the company also took the opportunity to announce the availability of a new Wear Indicator Tool that is easy to use and can help to identify the signs of wear in both belt and pulley.

Micro-V Horizon made from EPDM

Signs of wear

It’s essential to understand the wear process. As belts made from EPDM age, they gradually lose rubber material. It’s a similar story to the loss of tread in tyres and there are consequences for vehicle safety, too.

For example, a loss of belt material will change the belt profile, with the following potential implications:

a) Less tension to the belt

b) Belt slip

c) Reduced power to dependant systems such as power steering, cooling and electrical systems

Belts must be inspected for material loss in order to guarantee that they can deliver the power required consistently, without the risk of failure. As such a different diagnostic approach is required (pictured below).

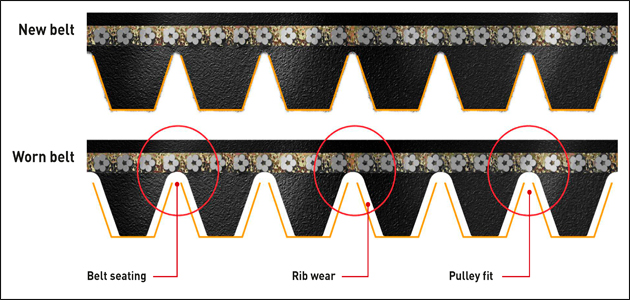

Pattern of wear

The diagrams (below, left) show the pattern and progress of wear on a new belt made of EPDM. As it gets older, note that material is lost from several areas. There is loss of material at the sides of the ribs and at the belt seating points. This increases the area occupied by the pulley, which must fit perfectly in order to perform efficiently. The wider space adversely affects the overall performance and provides greater opportunities for slippage.

The degree of wear to the belt can be easily detected with the help of the Gates Belt Wear Indicator Tool, which can also be used to check for wear on the pulleys (pictured below).

Testing for wear

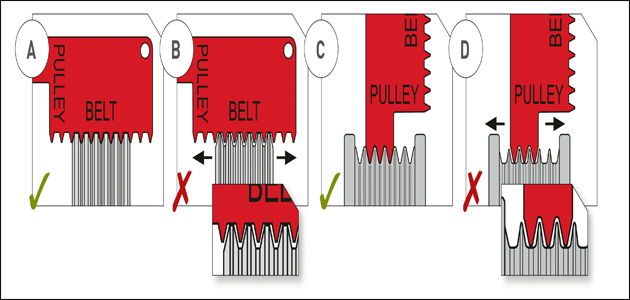

Testing belts and pulleys The Wear Indicator Tool has two separate profiles. The broader profile is for the belt, while the narrower profile is used for assessing wear to the pulleys.

With the belt still fitted to the ABDS, reach under a straight section of the belt and insert the broad ‘belt’ profile into the grooves between the belt ribs. The teeth of the indicator must fit perfectly within the profile of the grooves of the belt. No side-to-side movement must be possible without lifting the tool out of the belt grooves. If movement is detected, either excessive material has been worn away from the belt or the belt is operating at less than optimal power transmission.

Testing for wear to the pulleys is even more straightforward. Once again, testing can be carried out while the ABDS belt is fitted. The teeth of the tool must fit perfectly into the pulley, with only a thin parallel space evident between the pulley and the teeth of the tool.

If side-to-side movement is possible either excessive plastic or metal has been worn away or pulley-ribs may be rounded instead of straight. A new belt running on a pulley that has not been replaced will have less than optimal grip and its power transmission capabilities will be compromised.

ABDS considerations

Note that technological innovation within the ABDS means that some VMs have replaced ordinary crankshaft pulleys with Torsional Vibration Dampers (TVDs), which absorb vibration and improve the engine’s noise, vibration and harshness (NVH) characteristics. Overrunning Alternator Pulleys (OAPs), which allow more heavyduty alternators to ‘freewheel’ or ‘overrun’ whenever the engine decelerates, are increasingly found inside the modern ABDS. As a result, Gates recommends that all components are replaced simultaneously.