The heater resistor is also known as the heater blower motor resistor or blower speed controller because it fundamentally controls the fan speed of the interior heater. Here, ELTA Automotive’s TechASSIST team looks at the different types of resistors, the causes and symptoms of failure, and offers advice on diagnosing faults.

Original type heater resistors

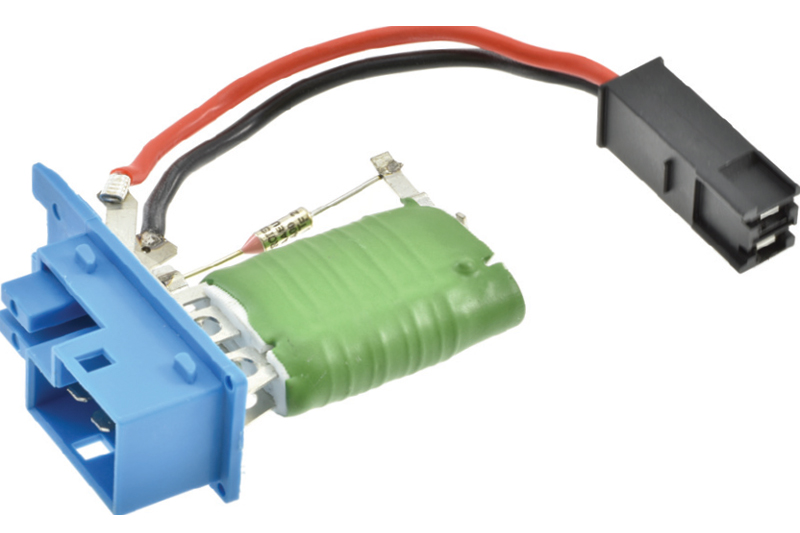

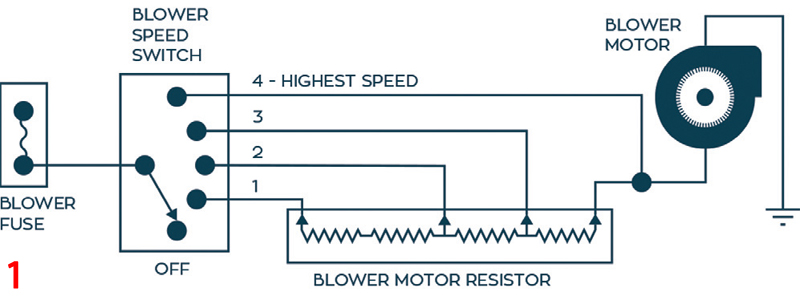

The original resistor-based blower motor control was a simple resistor winding arrangement. Vehicles fitted with this type of resistor would typically have four fan speed settings for the driver to choose from; the resistance is changed and the voltage through the motor is increased or decreased to control the speed of the blower motor/fan (Fig 1).

Modern type speed controllers

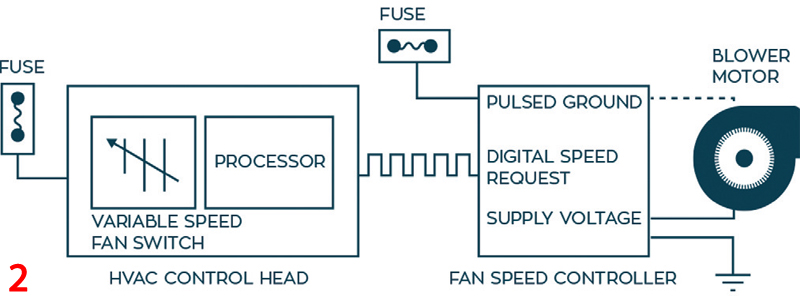

Modern vehicles with automatic climate control feature variable speed blower motors that use a blower speed controller rather than the traditional four-speed resistor. The driver inputs the required temperature settings via the HVAC control head, which sends a digital signal to the blower motor speed controller. The speed controller then uses the information to pulse either power or ground to the blower motor, accurately controlling the fan speed (Fig 2).

What causes failure?

The heater blower is one of the most commonly used cabin functions, so it is no surprise that these components are prone to simply wearing out. Other causes can include:

- Damaged wiring:Wiring and connectors to and from the heater resistors draw a lot of power from the vehicle’s electrical system, and this in turn causes high temperatures that can damage wiring and connectors

- Failed blower motor: A failed or failing blower motor can draw too much power and damage the resistor and wiring

- Leakages: In some cases, the heater core can leak coolant onto the resistor and/or blower motor causing damage and failure

Symptoms of failure

A failed resistor can result in several outcomes.

- Fans stuck on one speed: The purpose of the heater resistor is to control the speed of the fan/blower. Therefore, when variable control of the fan is lost, it is likely that the resistor has failed. Often the fans will only run at maximum speed as the faulty resistor cannot reduce the voltage to the motor

- Fans not working at all: Sometimes, resistor failure results in complete fan/blower failure and vice-versa. If the fan does not function, the resistor may be at fault.

Always test before replacement

It is important that tests are conducted to identify the heating component that needs replacing and the causes of failure.

First, visually inspect the system for leaks from the heater core. If the heater core is leaking, this should be resolved before replacing further components.

Next, check for damage to wiring and connectors, and replace if required. Note that whilst damaged wiring and connectors could be the sole cause of the blower not functioning, the damage could have been caused by a failed resistor or motor drawing too much power. Therefore, continue to check further components.

You should then test the blower motor using an ohmmeter against specifications. If the motor is drawing too much power, it may be failing and could cause damage to any newly fitted resistors or connectors in time. If the motor has failed, it will need to be replaced, but continue to test the resistor and wiring as the failure may have damaged those components too.

Finally, visually inspect the resistor for signs of corrosion, then check the resistance between the terminals with an ohmmeter against specifications. Readings should usually be around 0-5 ohms. If an open circuit is reported, then the component has failed.