What’s the most common cause of a noisy Auxiliary Belt Drive System (ABDS)?

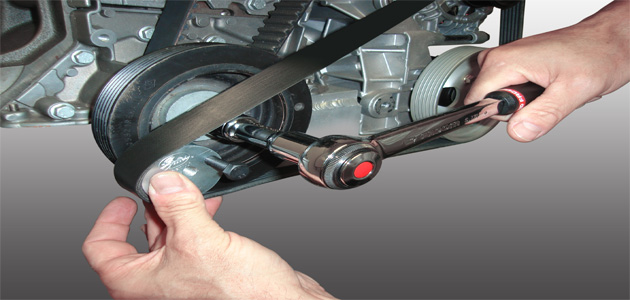

There is no single cause, but there is a common suspect. The belt is usually blamed and that’s often because replacing it will normally cure the noise. This is only a temporary respite as the symptom has been addressed rather than the cause. It could be misalignment or it could be wear to another component. The only way to identify the cause is to take a holistic approach and to examine the entire drive system for wear as well as any irregularities. That should include an examination of all of the components in the ABDS.

Overrunning Alternator Pulleys (OAPs) are expensive, but isn’t it true that a solid pulley will work just as well?

It sounds like your first priority is to save the customer money, when your true responsibility is to deliver the most appropriate repair. The OAP is a vibration damper and is installed in the ABDS to take out vibration. A solid pulley has no damping effect. It would run, but in our experience the consequences are all bad, including extra noise in the drive system. The tensioner could also rapidly deteriorate, leading to premature failure of the belt.

Is it OK to replace a Torsional Vibration Damper (TVD) with a solid pulley?

Torsional Vibration Dampers (TVDs) are usually located in the Auxiliary Belt Drive System. They were introduced to absorb vibration from the crankshaft and produce much smoother drive system operation. They are required as a result of the increasing number of components in the drive system and are found on most late models of passenger cars and light commercials.

Without this damping effect, the vibration would be transmitted through the ABDS and can lead to premature belt failure. It is also worth noting that as the timing belt is also attached to the crankshaft, the absence of a TVD would have adverse implications for the SBDS. The additional vibrations can eventually contribute to de-lamination of the timing belt.

A failing TVD can cause the noise and vibration that many mechanics erroneously believe to be the belt or the tensioner.

If the automatic tensioner is still tensioning the belt, doesn’t that mean it is still OK?

Appearances can be deceptive. Although the spring part of the tensioner applies the tension to the belt, the internal damper assembly could be worn. If that is the case, the tension will be fine while the belt is static (engine off). Once the belt is in dynamic mode (engine running) a worn assembly will eventually cause the belt to flap around.

Assuming this is a scheduled replacement, the tensioner has already endured the same amount of work as the belt – one complete duty cycle. It’s asking a lot for it to complete another one. If you are replacing the belt, we recommend you change the tensioner too.

Stretch Fit ABDS belts seem to be on the increase. Are there any other ABDS belt developments on the way?

There is a new kind of belt compound on the horizon and it has arrived in the form of a completely new belt. It was developed by Gates and was introduced to the aftermarket at the Automechanika show, in Frankfurt, last month.

The Micro-V® Horizon™ is a multi-ribbed belt that has been developed for today’s more compact and more powerful engines, which are equipped with engines that place different demands on drive belts.

The new belt compound is designed to increase flexibility and reduce noise in the ABDS.