Running a diagnostics test is no easy task, and with the influx of electric and autonomous vehicles on UK roads, it looks to be getting even harder. ACtronics updates PMM on the do’s and don’ts when trying to pinpoint a vehicle fault.

As the technological trend moves more towards modern cars and vehicles being electric and autonomous, more and more electronic components, sensors and modern technology are being implemented and used in such vehicles.

With the increasing amount of technologies that is being added, it is important that they are correctly diagnosed when they are faulty, as the problem could be caused by many different issues in many different units.

FAULT CODES

Here is a very brief explanation of fault codes and their meanings:

P codes = Powertrain

C codes = Chassis

B codes = Body

U codes = Network Communication

In most garages these days, you will find a diagnostic tool of some description. When your engineers are diagnosing vehicles with electronic faults, it’s not just a case of plugging in the diagnostic tool and hoping that it will tell you your exact problem; you might find that there is a variety of different codes in there, which could be causing the same problem.

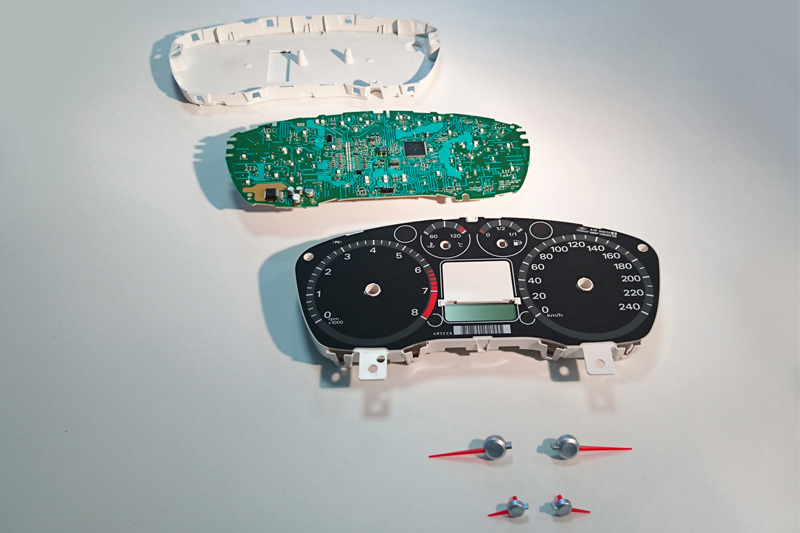

Let’s take one of our common units into consideration, the Ford Focus II instrument cluster (pictured). When this is faulty, there is usually a whole host of issues and faults with it. This may include the failure of all illumination on the instrument cluster, with warning lights either wrongly illuminating or failing to illuminate at all, whilst the gauges often register nothing, causing the car to go into limp mode or possibly fail to start.

Nowadays though, a lot of car owners will own OBD tools to self-diagnose at home to try and save money, but often do not have the experience or knowledge to be able to properly diagnose where the fault is, and would rather believe that the fault lies where the reader says.

Without proper diagnosis, there could be multiple areas where the fault may lie as there are many units connected by canbus lines, which, in turn, are getting connected to different sensors across the whole of the car. This is why it is so important to have knowledge of diagnostics when testing for faults, especially when electronic components are involved, as it could result in wrong parts being delivered, and consequently costing money unnecessarily.

If we go back to the Ford Focus II instrument cluster, an easy mistake to make is to assume that, if the vehicle is failing to start, then the fault must be mechanical.

However, if you are still unable to find the fault, this could lead you to look for an electrical fault, which could be forgiven, if you looked towards the Engine Control Unit (ECU) for the fault, especially when there are various fault codes displayed. Yet, it is most common to see ‘U codes’ such as ‘U1900-20 (CAN) Communication Bus Fault – Receive Error’ or ‘U2510-20 CAN – Invalid data for vehicle security’, to name only a few.

So, if you were to get one or a number of the common ‘U codes’ relating to a Ford Focus II with any of the issues mentioned earlier, it would be fruitful to look along the immobiliser network, which contains the instrument cluster, ECU and key, and inspect the continuity between all three.

With these issues, we usually see the fault within the instrument cluster, which is typically due to a fault on the Printed Circuit Board (PCB), caused by cracks in the network and pins throughout the PCB. This is why it’s important to be able to diagnose a car properly when using diagnostic tools, because fault codes can point you in the right direction, but not pinpoint the fault itself.