One of the reoccurring repair issues that has become a problem for the independent workshop is the failure of the idler pulley on the 1.7 diesel engine fitted to many General Motors (GM) vehicles such as the Vauxhall/Opel Astra, Combo, Corsa, Mariva, Vectra and Zafira.

Catastrophic consequences

Although the problem ultimately stems from the timing belt being too tight, it reveals itself in damage to, and very often the subsequent failure of, the idler. The pressure exerted on the idler when too much belt tension is applied can result in its distortion and breakup, with the obvious catastrophic consequences.

This is a potentially costly and damaging outcome, so it is therefore vital that technicians fit an original equipment (OE) quality timing belt such as a Dayco High Tenacity (HT) belt – which is the OE fitment for the majority of diesel engines used by European vehicle manufacturers – and take great care to adopt the correct belt tension when undertaking this repair.

The ‘cup’ structure (left) with the ‘plain’ pulley (right)

To further complicate the repair for the independent, GM supplies two different styles of idler for the engine. For earlier versions of the engine, it uses an idler with a ‘cup’ structure, with the original reference 97129939 (636730 for Opel) and the Dayco reference ATB2064. However, on more recent engines it uses a ‘plain’ guide pulley, with the reference 97376296 (636928 for Opel) and the Dayco reference ATB2516 (see image above).

Despite the fact that both versions of the idler have been designed and produced to withstand the stresses of the engine to which they are fitted, it is essential that the timing belt is fitted following the correct procedure and adjusted to the tension specified by GM.

Timing belt tension

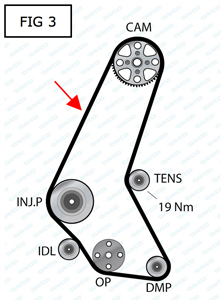

As aforementioned, failure to set the correct timing belt tension could result in the failure of the idler (see image below), so Dayco recommends the use of a quality belt tensioner tool like its Tensiometer to ensure that the correct tension is obtained and reliable timing belt performance maintained.

A failed idler — the result of incorrect timing belt tension

This is done by ensuring the tension is correct between the camshaft and injection pump pulley (pictured below). To do this, use the Tensiometer and insert the unique test code (1262028) and measure the span of the belt in the normal way. If the tension reading on the tool is high, represented by up to three “+” signs then the tensioner must be completely released and the full tension procedure must be adhered to until the digital display on the Tensiometer says “OK”. If the tension is too low, represented by up to three “–“ signs, then it is possible to adjust the tension spring with the allen key until the digital display reads “OK”. The tensioner MUST not be altered under any other circumstance.