The Citroën C1 was created in 2005 from a joint project between PSA Peugeot Citroën and Toyota. This popular city car has sold over 64,000 models in the UK and is starting to become a regular sight in the aftermarket.

Replacing a clutch on the C1 can be a little tricky, but with the guidance of LuK the whole process will become much easier. Nothing out of the ordinary is needed to complete the job, the only special tools required are a transmission jack, an engine support beam and a long axle stand. A two-post ramp was used in this example as a four-post ramp may not provide enough clearance.

For safety reasons its considered best practice to disconnect the battery earth lead before commencing work. If the vehicle has alloy wheels it may be fitted with anti-theft wheel bolts, so make sure you have the key before you start.

Disconnect the battery cables, remove the support clamp and lift the battery out. Undo the small satellite fuse box (not forgetting the hidden bolt at the rear (pictured below)) and stow it to one side.

Release the attached wiring harness from the battery tray and remove the tray, making sure you find the hidden bolt through the hole on the tray (pictured below).

Remove the securing clips on the gear linkage cables (pictured below) and the large tension spring. Undo and release the clutch cable from the transmission and stow it to one side. Unclip the reverse light switch and remove the bracket.

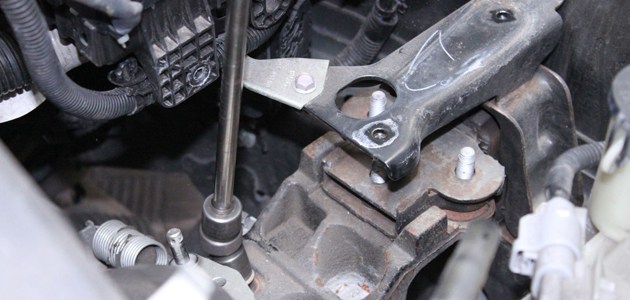

Install the support beam and undo the upper bell housing bolts and the starter motor upper bolt. Remove the gearbox supporting bracket (pictured below).

Remove the gearbox cover plate

Raise the vehicle and remove the N/S/F wheel. Remove the gearbox cover plate above the exhaust and disconnect the oxygen sensor. Drain the gearbox oil and undo the lower arm (pictured below) castle nut and pin and release the N/S drive shaft.

Undo the final starter motor bolt (pictured below, left) and remove the rear gearbox mounting (pictured below, right). Finally remove the remaining lower bell housing bolts and, while supporting the gearbox, pull it back to access the clutch and release bearing.

With the clutch removed, check to see if the vehicle has a Dual Mass Flywheel (DMF) fitted. If it has it will need to be checked for signs of heat stress and evidence of grease loss. The DMF should also be tested for freeplay and rock between the primary and secondary masses – LuK tool number 400 0080 10 is specifically designed for this purpose on all LuK manufactured DMFs. Full instructions and tolerance data for all LuK DMFs are contained on a CD which comes with this special tool.

Clean the first motion shaft splines and any debris from the bell housing (especially important when a release bearing has failed). Put a small dab of high melting point grease (not a copper-based product) on the first motion shaft splines and make sure the new driven plate slides freely back and forth. This not only spreads the grease evenly but also makes sure you have the correct kit. Wipe any excess grease off the shaft and driven plate hub. Using a universal alignment tool and checking the driven plate is the correct way round (note ‘Getriebe Seite’ is German for ‘Gearbox Side’), the clutch can be bolted to the flywheel evenly and sequentially.

Before fitting the gearbox make sure the locating dowels are in place and not damaged, refit any that have become dislodged. Inspect the release fork, cross shaft and bushes for wear and tear and refit the gearbox. Make sure the gearbox bell housing bolts are secured before lowering the jack. Refitting is the reverse of the removal.