Compound disc brakes are lighter than standard brake discs and therefore reduce carbon emissions. It is essential technicians are familiar with their properties. Bosch provides some Best Practice advice on how to work with them.

The compound brake disc is a new product innovation in lightweight design, comprised of a profiled aluminium disc chamber, combined with a high-carbon cast iron friction ring. The two components are held together by stainless steel rivets.

Compound brake discs feature various materials, binding methods and designs, depending on the vehicle model. Advantages over standard cast iron brake discs include:

- Lightweight component design results in lower fuel consumption and reduced CO2 emission

- Reduced unsprung mass improves driving comfort and performance

- Enhanced thermal capacity and heat conductivity reduces brake judder. Another advantage is that the friction ring is highly resistant to thermo-mechanical stresses

- The friction ring and rotor hat are joined using a special method which further reduces undesired heat flow. This reduces warping and hot tears, as well as vibration and noise

Bosch compound brake discs follow the OE hat material concepts (steel and aluminum hat) combined with the robust market proven connection concept (rivet) in order to provide premium aftermarket advantages in line with concepts in OE. All Bosch compound brake discs are ECE R90 certified and therefore offer customers the same quality as OE components. Their material composition and tolerances are optimally adapted to the brake system of the designated applications. Bosch compound brake discs also come with the required studs and feature an Alutherm coating for corrosion protection.

Handling and installation

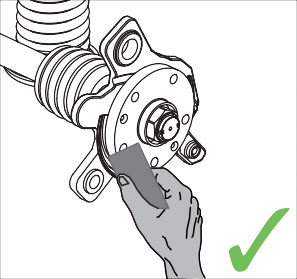

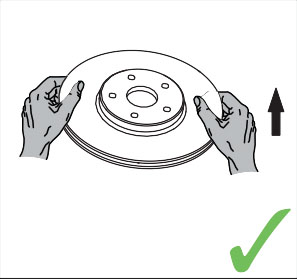

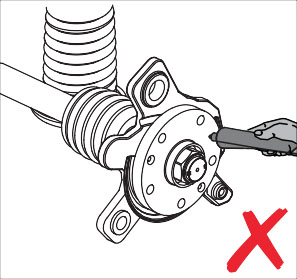

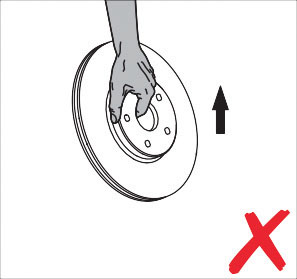

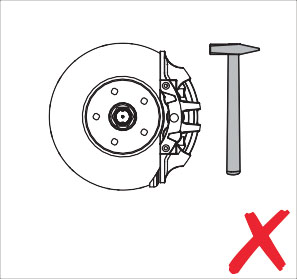

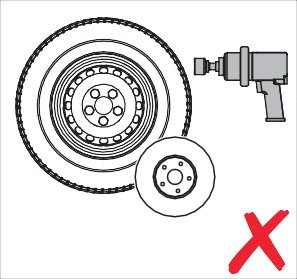

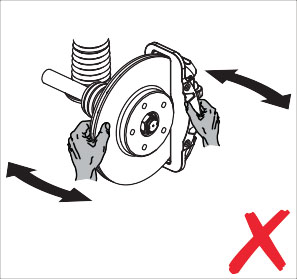

Compound brake discs are very sensitive, high-quality products. Special requirements and safety precautions are involved in the handling and installation of these components.

DO

DON’T

Tightening

Always use a torque wrench to tighten the screws of the compound brake discs. Tighten the wheel screws evenly in three stages to the torque specified for the vehicle.

- Evenly tighten the wheel screws crosswise using a torque wrench, max. 30% of the rated torque specified by the vehicle manufacturer

- Tighten crosswise to 60% of the rated torque specified by the vehicle manufacturer

- Tighten crosswise to 100% of the rated torque specified by the vehicle manufacturer

After repair, the brake system should be bedded in somewhat if possible. Be sure to follow the vehicle manufacturer’s installation, assembly and safety instructions.