Shaftec explains why, in the case of gaiters and boots, prevention really is better than cure.

Winter woes

Road salt lowers the freezing point of water. In a chemical process, it turns ice back into water and creates traction between the tyres and the road surface, meaning the vehicle won’t slip on the ice. But as vital as salt and grit are for safe winter driving, technicians need to be aware of the corrosive qualities of these substances and the subsequent effect they can have on vehicles coming in during, or just after, the winter season.

Are your boots up to the job?

Are your boots up to the job?

On a vehicle, a gaiter – or, to give this part its industry nickname of ‘boot’ – refers to a protective and flexible sleeve covering a moving part. This sleeve is intended to keep the part clean. Within the steering and suspension system, they are rubber covers which seal each end of the car’s steering rack or constant velocity (CV) joint. They seal in lubricant and keep out dirt and water while still allowing movement of the steering parts and driveshafts. To distinguish the parts, at Shaftec the steering rack cover is referred to as a ‘gaiter’, and the term ‘boot’ is used to identify the CV joint cover.

Prevention is cheaper than cure

For a safe and efficient drive for the customer, and to make sure they get the most out of expensive steering components, technicians need to go back to basics and regularly check the more perishable parts. A split gaiter or boot may compromise the vehicle’s next MOT. A split boot will fail and any cracking or deterioration will warrant an advisory notice.

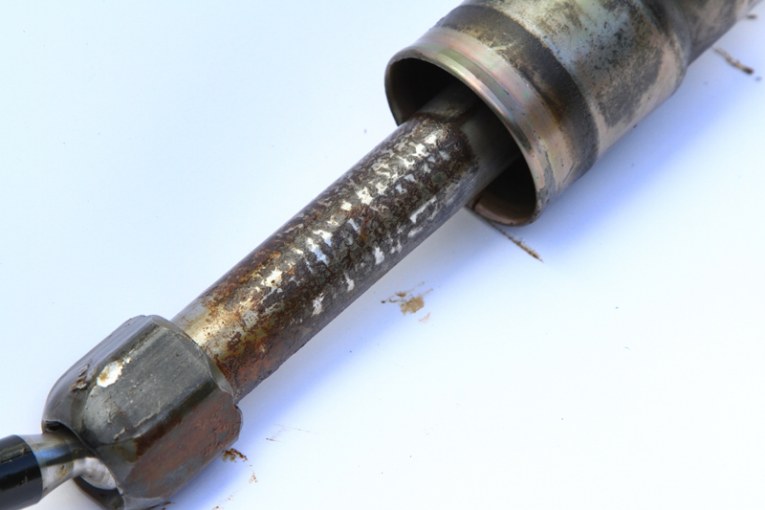

If a visual inspection reveals that the gaiter is starting to crack, split or perish, replace the part immediately. A hole, gap or split in the rubber which lets in water and dirt will cause rapid wear and rust. This will lead to steering stiffness or play. In addition, rust will damage the seals from the outside, and contaminated fluid will damage the seals from the inside. The bottom line is that ignoring a damaged gaiter or boot will eventually lead to part replacement, which could be costly but is in many cases avoidable. Boots made of thermoplastic material instead of rubber are more susceptible to cracks and splits as they lack flexibility and can become brittle more quickly. Whilst the boots are off the unit, it makes sense to take the time to inspect the rack bar for any signs of rust or wear, along with signs of steering fluid. All these signs would necessitate the replacement of the steering rack as failure is inevitable.

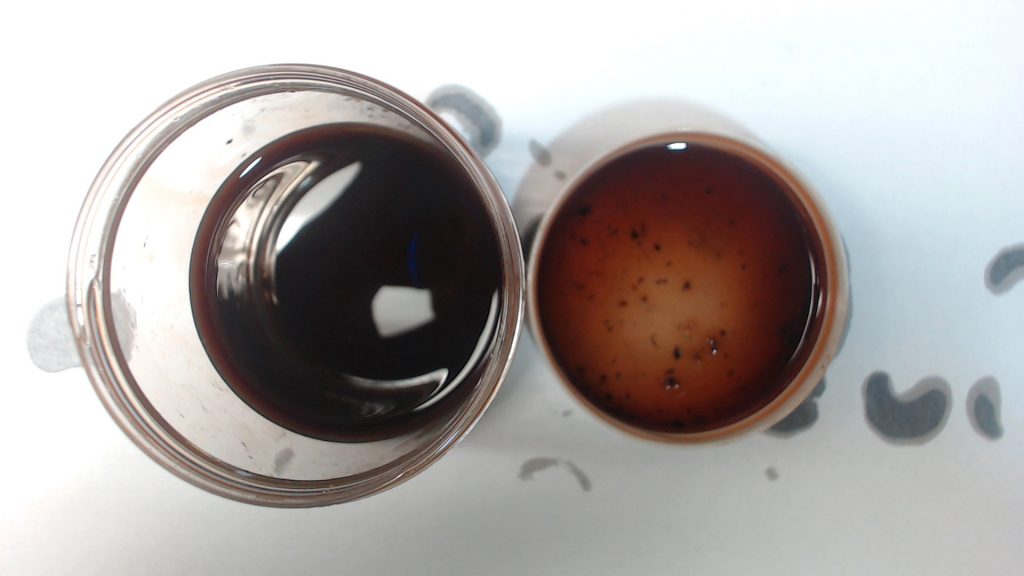

The good practice of replacing the steering fluid is also recommended on a regular basis. Low fluid levels make steering difficult and parts can become damaged or could signal a leak and thus a bigger problem. Over time, systems deteriorate and small particles start to break off. Furthermore, fluid oxidises as it ages, making it less efficient. The smallest piece of remaining debris could damage a seal and cause a leak, unit failure or a jammed valve due to the high pressures the steering systems work under.

Pumps and racks will live longer if the system is flushed regularly. The best way to do this is by using a flushing machine and a steering flushing agent. If these are not available, running 5L of steering fluid

through the system is recommended to flush out any contaminants. Don’t forget to clean out the header tank/reservoir as most of the debris will settle here and failure to do this will render all other efforts to cleanse the system a waste of time.