PMM hears from a number of leading battery and charging specialists, to find out what technicians can do this winter to maximise business and make sure their customers keep coming back.

Winter takes its toll

The performance and lifespan of lead-acid batteries can be seriously inhibited when exposed to temperature extremes, and as a result, effective battery management and support during winter servicing is essential for the wellbeing of both the battery and indeed your workshop’s reputation, says CTEK.

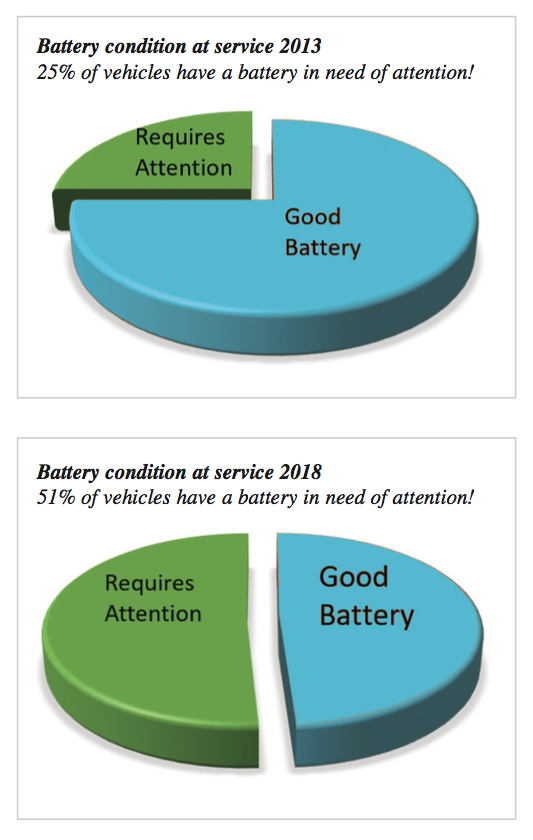

Indeed, following a recent workshop trial carried out by CTEK in partnership with PMM, we know that as many as one in two vehicles entering the workshop has a battery that needs attention. When you compare this statistic to a similar trial we undertook back in 2013, which saw only 25% of vehicles with a battery requiring attention, we see the risk of battery failure has significantly increased.

Batteries age in summer and fail in winter

According to JOHNSON CONTROLS, the company behind the VARTA brand, it’s not just the winter that causes problems for batteries. Winter is certainly the time when cold weather proves too harsh for a weak battery to survive – but this is magnified if it was preceded by an extraordinarily long and hot summer – like last summer.

Heat dramatically shortens the lifespan of a battery, so by the time winter comes around, older batteries are close to their limit.

“Many drivers think that it’s just cold weather that causes damage to the battery, but it is the heat that is the start of its downfall,” explains Dr. Christian Rosenkranz. An outside temperature of 20°C is optimal for a car battery. In the summer of 2018, the temperature often climbed over 30°C.

High temperatures lead to self-discharge of the battery and cause its electrochemical parts to age more quickly. “These effects may not cause the battery to fail immediately, but they can jump-start the deterioration,” says Rosenkranz. Whilst this development remains unnoticed throughout summer and autumn, the problems start to show in winter, when more energy is needed to start the engine. For this reason, the battery should be checked regularly throughout the whole year.

Apart from extreme temperatures in summer and winter, there are many other reasons for battery failures. If the car is used infrequently or only for short distances, the alternator cannot fully charge the battery, while electrical consumers such as the rear window and seat heating contribute to further battery discharge. Long downtimes should be avoided if possible, because in many modern cars the battery has to supply energy even when the engine is switched off. Systems such as alarms, door locks, keyless-go functions and navigation systems need energy even when the car is parked. Especially in winter, drivers should therefore try to make a longer journey at least once per month for the battery to be fully re-charged.

The battery test and charge service

The Rotronics team always recommends that independent workshops offer a simple Battery Test and Charge service for every vehicle that enters their premises. You can then identify all opportunities in supporting your customers and their vehicles with just a few simple steps:

1. Test every vehicle’s battery using a diagnostic battery tester, as part of your winter inspection programme.

2. Notify the customer/owner of the outcome – the battery is:

a) Good – fully charged (no action required);

b) Faulty – needs replacing (offer a replacement).

Offering this service helps you show your customer how to prevent an issue before they are standing at the side of the road in the snow or rain. It also presents you with additional revenue streams by giving you the chance to identify a faulty battery and, more importantly, replacing it.

Why should garages consider battery management?

The importance of effective battery management over winter is advocated by ROTRONICS, which is the UK partner for CTEK and Midtronics battery management technology. According to the company, the inevitable fall in temperature at this time of year will significantly affect a battery’s performance and, in extreme temperatures, this can mean as much as a 50% dip.

There are increased power demands on a vehicle due to the darker, colder nights: lighting, heating systems, electrics, heated seats and de-misting windows, which, all together, put an excessive drain on the vehicles battery and charging is vital.

The battery is often overlooked, yet it’s one of the single most important components of the vehicle. Many vehicle batteries in use today will be in a discharged or semi- discharged state. The vehicle’s alternator is not able to cope with the high demands of the modern consumer requirements, especially when the vehicle is driven on numerous short start/stop journeys. A battery voltage should always be above 12.4V to prevent sulphating of the cells (the most common cause of battery failure) reducing performance and serviceable life of the vehicles battery.

A few battery facts

- Battery performance can reduce by 35% when temperatures hit 0°C and fall by as much as 50% if temperatures go even colder

- At freezing temperatures, an engine’s starting power requirement can increase by as much as 250% when compared to that of a summer’s day

- Low temperature affects the chemical reaction in the battery, and this makes the alternator even less effective as the battery will take longer to charge.

According to CTEK, simply by charging and conditioning batteries during a regular service, workshops can ensure that their customers are protected against flat batteries and other battery-related breakdowns during the cold winter months. CTEK has a fast, safe and effective solution that will enable workshops to charge batteries without the removing the battery from the vehicle or interfering with vehicle servicing procedures.

CTEK chargers are claimed to be powerful, fully automatic switched mode battery chargers designed to offer outstanding levels of reliability, safety and efficiency. They are said to be easy to use and require no specialist knowledge or monitoring – simply connect, forget and carry on with a normal service without worrying about the risk of overcharging and gassing. CTEK battery chargers are compatible with all types of lead acid vehicle battery, including wet/flooded, calcium, gel, AGM and EFB and for some models, Lithium-Ion (LiFePO4) batteries too.

When it comes to charging, VARTA’s Dr Rosenkranz supports the view that it should form an essential part of a garage’s winter strategy: “Battery testing helps to indicate upcoming failure. Therefore, drivers should have their batteries checked by workshops at least once a year before winter. This keeps them on the road and protects them from additional costs and hassle. Nothing is more annoying than a battery that is still strong enough to turn on the lights, but too weak to spin the starter.”

New battery technology entering the aftermarket

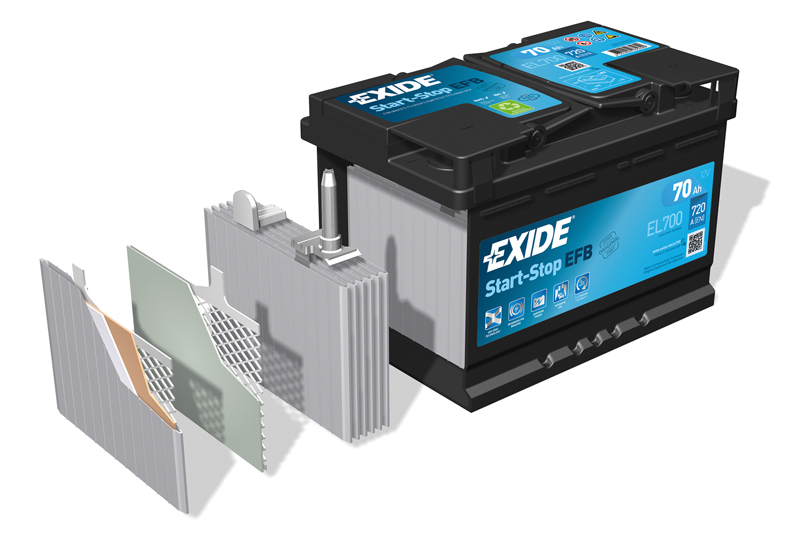

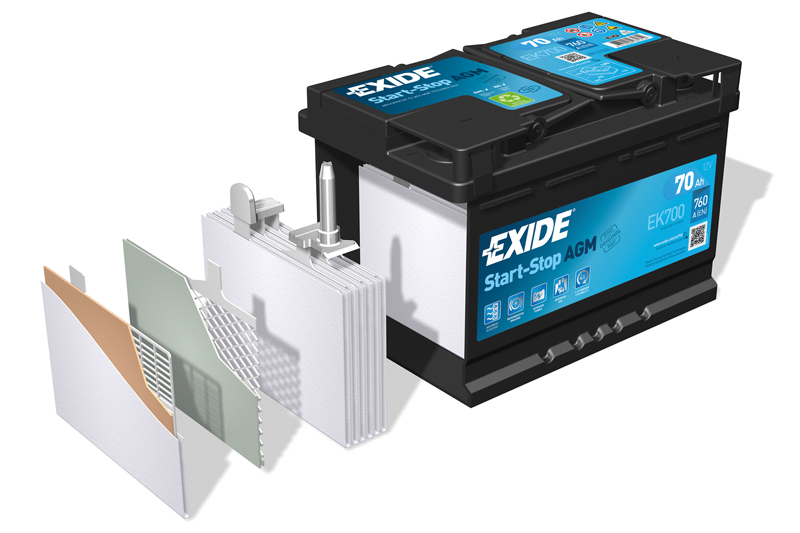

More and more Start-Stop cars are entering the aftermarket, the global Start-Stop market is growing 20% annually, and the Start-Stop powertrain is quickly becoming the preferred option in the UK and around the world, explains EXIDE TECHNOLOGIES. All this is being driven by the pressure on carmakers to reduce emissions, improve fuel efficiency and meet aggressive targets set by legislators.

Exide lays claim to having invented the first Start-Stop AGM battery in 2004 and the first Start-Stop EFB battery in 2008. Both technologies have made impressive gains in efficiency and performance since then, and have been adopted by many of the world’s leading carmakers. Exide estimates that Start- Stop batteries will be the majority of aftermarket battery sales in the UK by 2022.

“Exide’s Start-Stop batteries have far better electrical performance, power, cycle life and charge acceptance than a standard lead-acid battery. This means they can handle the frequent starting and stopping from the Start-Stop powertrain,” says Craig Everett, UK Marketing Manager at Exide Technologies. “A conventional lead-acid battery is not compatible with a Start-Stop car. In fact, fitting one will void the warranty, creating a financial liability for the retailer.”

Support for workshops

Start-Stop provides a range of exciting opportunities for workshops to grow their business, capture market share from competitors, and position themselves for the future. Exide is ensuring that all its workshop partners have the right level of support to navigate Start-Stop, so they in turn can offer superior service to their customers.

The company is helping its customers make the most out of Start-Stop and the broader opportunities in the aftermarket. This includes providing point-of-sale materials to showcase their expertise, the best fitment information, and a range of specially designed workshops tools.

As discussed above, when temperatures start to fall and winter is just around the corner, it is time for drivers to take their car to the workshop and get it ready for the cold season. Exide believes that, all too often, batteries are often overlooked, while changing tyres, testing lights and refilling fluids are all standard procedures. Ultimately, the message to get across to customers is: will your battery make it through the winter? The only way to find out is to have it checked by a workshop.