Arnott Europe, a specialist in air suspension systems, has noticed that there is a lot of misinformation out in the industry regarding air suspension. Here, the company runs through the basics that every technician should know about the component category.

How air suspension works

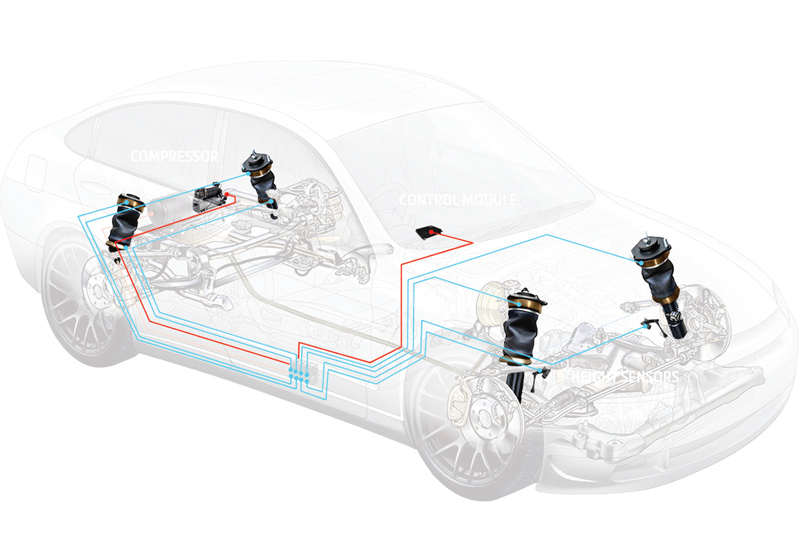

Air suspension systems use a compressor to inflate rubber air springs; these may be separate from the shock absorber, or combined with the damper as an air suspension strut. Height sensors give the ECU (Electronic Control Unit) a signal when the vehicle is not at a predetermined height.

The compressor then pumps air into the air springs until the proper height is reached. Like all rubber components, air springs and struts are wear and tear parts. Typically, the rubber will eventually dry rot, with small cracks appearing where the air bladder rolls up on itself. On average, an air suspension part will need to be replaced in six to 10 years. Mileage, climate, driving conditions and off-road usage will also influence the replacement rate.

Diagnosis and repair

If there is a problem with the air suspension on a vehicle, the customer will first notice one corner, side or the entire vehicle sitting lower than normal. However, once the car is started the compressor might be able to maintain adequate pressure and ride height.

Unless the leaks are fixed, these tiny holes will eventually grow larger than the air compressor can sustain, or the pump may simply burn out due to overheating, causing additional expense.

At that point, the customer will find that the vehicle is unable to level itself or a dashboard warning light may come on indicating the compressor has failed. If the air suspension is no longer functioning, the customer may not be able to drive it or the ride may be harsh and uncomfortable, making a replacement absolutely necessary.

Compressor problems

An air suspension compressor failure is usually caused by a leak in the system. After replacement, check the air springs and other components and immediately replace any leaking components or the pump will fail again, voiding the warranty.

An air suspension leak is easy to find by spraying the air springs, struts and fittings with a soap and water solution. Bubbles will indicate where the leak or leaks are.

It should also be noted that air suspension parts should be replaced in pairs where appropriate. For example, Arnott rear air springs for the Mercedes-Benz E-Class W211 must be replaced in pairs, as the company has improved the air spring and piston design. As a result, installation has become faster and easier because of these improvements. All other Arnott air springs and struts may be used next to the OE part.

Finally, some compressor may require a software update after installation; Land Rover LR3, LR4 and Range Rover Sport are such examples. Since Land Rover moved away from Hitachi to another compressors supplier, a software update has become mandatory. Without this update, the compressor may not function well and this could void the warranty.