Dayco has encouraged businesses to take a similar stance to a workshop in Devon who is offering a fixed price for timing belt replacement on the Ford 1.0-litre EcoBoost engine.

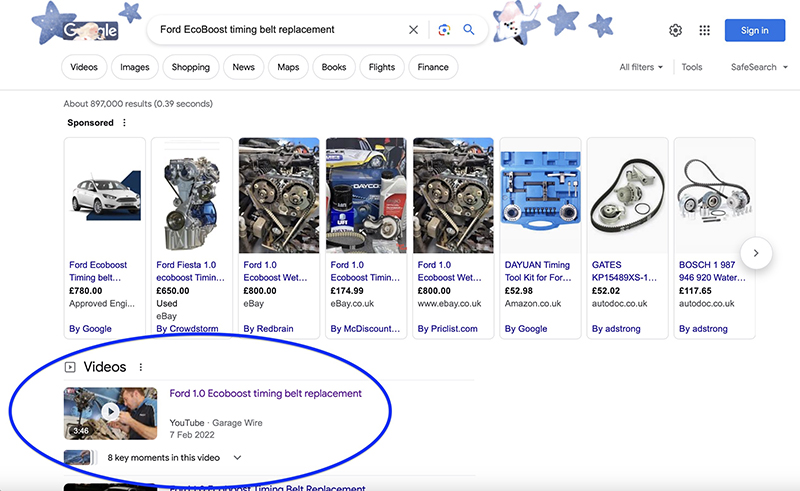

Dayco’s National Sales Manager, Steve Carolan, explained: “According to the article, and after trying it myself, I can verify, a search for ‘Ford EcoBoost timing belt replacement’ in Google lists the workshop, and its service offer, on the first page, which is a great achievement.

“Finding a niche and being proactive are both principles that deliver huge benefits and as a supplier of OE components into the independent aftermarket, Dayco applauds this approach and encourages other workshops to take a similar stance.

“Naturally, we are here to help with the like-for-like OE replacement parts for this engine, and literally hundreds of others, but we also provide technical support through published fitting advice and instructional videos, one of which concerns the installation process for replacing the timing belt on the 1.0-litre EcoBoost, which incidentally, is ranked number one of the non-sponsored listings, on the same internet search!

“The 1.0-litre EcoBoost engine is used in several Ford models, so independents will already be familiar with it, but the belt replacement process isn’t without its issues, so we encourage technicians to view our video before undertaking the job, as it highlights a number of important factors that need to be kept in mind.

“Among these include the sealant that must be used on the timing belt cover and the sump, to ensure there is no leakage when the engine is refitted and refilled with oil. It is strongly recommended that this is sourced through a Ford dealer, as its specification is crucial and it only has a 10 minute window before it starts to become hard and unmanageable. It is also wise to replace the crankshaft oil seal before refitting the timing belt cover, but easier to fit the new one once the cover is secured in place, and replacing the water pump is another best practice principle.

“Two crucial steps are also important, the first is to fit a new friction washer, which is a part that is not fitted when the engine is originally built and only comes into play when a timing belt replacement is carried out, and the second the correct torque value and process for tightening the replacement crankshaft pulley bolt, which at 300Nm plus 90°, requires a torque multiplier for the final tightening.

“Applying these principles and using the appropriate Dayco timing belt and water pump kit (Dayco KBIOWP020 or KBIOWP030 dependent on the engine variant) other workshops can also tackle this replacement with confidence and in the knowledge that they are able to make a first class repair.”