Meyle is arguing that high quality parts should be a must-have for garages and customers alike and are easily obtainable within the aftermarket.

Studies show that over 70 per cent of vehicle owners choose high-quality aftermarket parts, appreciating their affordability and performance.

Why is that? Because certain modern aftermarket solutions now even exceed OEM standards, offering greater durability and reliability. For workshops, these parts are not only widely available but also ensure faster repairs and satisfied customers. Many aftermarket manufacturers have nowadays adopted cutting-edge production techniques, stringent quality control measures, and advanced materials to ensure their products meet or surpass the reliability and performance of OEM parts.

Meyle HD is a prime example of this evolution. Using advanced materials and technologies, it delivers parts that claim to outperform OEM components, making them more durable and reliable.

By choosing high-quality aftermarket solutions, workshops can build customer trust, reduce downtime, and increase profitability.

Going for durability

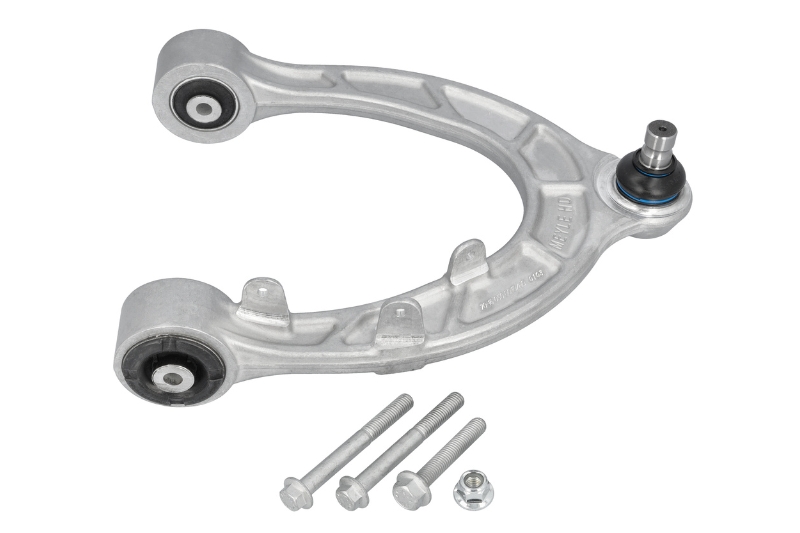

For workshops, durability is a key consideration. Quality aftermarket parts often incorporate improvements based on real-world feedback and technological advances. Meyle for example refines and optimises designs and materials in accordance with strict international regulations, addressing common failure points found in OEM components. A good example being control arms, brake pads or filters where Meyle frequently uses superior materials or innovative re-engineering.

These enhancements result in parts that resist wear and tear more effectively, offering extended service life. For workshops, this means fewer repeat repairs, fewer warranty claims, and a stronger reputation for delivering reliable solutions.

Won’t break the bank

While high-quality aftermarket parts may sometimes be priced similarly to OEM components, they often provide greater value over time due to their enhanced durability. These parts reduce the frequency of replacements, leading to long-term savings for both workshops and customers.

Moreover, the precision with which these parts are designed for specific problems and solutions results in significant time and cost savings for workshops.

The diversity in the aftermarket sector gives workshops flexibility in selecting parts tailored to specific applications. For instance, performance-oriented parts for enthusiasts, like the Meyle PD line, or higher durability options like the Meyle HD line, may provide specialised solutions that OEM parts cannot. This adaptability helps workshops cater to a broader customer base, while saving time and costs.

Unlike OEM parts, which must adhere to standardised designs and materials, aftermarket manufacturers like Meyle are free to introduce improvements and workshop-oriented solutions that leverage the latest technologies. For example, its control arm for Tesla Model 3 and Y, which not only impresses with its body that’s made of a one-piece forged aluminium but also with a bigger ball joint.

Customisation is another critical advantage. Workshops can use aftermarket parts to address unique client needs. This capability helps workshops differentiate themselves in a competitive market. Sustainability In an era of increasing environmental awareness, the aftermarket has taken some important steps in increasing its efforts: A lot of high-quality aftermarket parts are already produced with eco-friendly practices, such as recycling materials or reduced manufacturing waste. Additionally, the durability of high-quality aftermarket parts and solutions reduces the overall consumption of resources, aligning with broader goals of sustainability and environmental responsibility.stage.

For workshops, the decision to use high-quality aftermarket parts reflects a commitment to excellence. Customers rely on workshops for expertise and advice, trusting them to prioritise quality and durability. By consistently using reliable parts and solutions, workshops can establish a reputation for dependability, therefor nurturing and building customer loyalty.

In addition, offering high-quality parts can lead to positive word-of-mouth recommendations, as satisfied clients share their experiences with others. In a competitive industry, this reputation for quality can be a decisive factor in a workshop’s success.

Using high-quality aftermarket parts and solutions like Meyle’s HD line benefits workshops by enhancing reliability, efficiency, and customer satisfaction. The components exceed OEM standards, offering improved designs and materials for greater durability. Solutions like the company’s HD control arm for Tesla or VW streamlines repairs as well as pre-assembled kits, which further save time and simplify installation, boosting workshop productivity.

The use of high-quality aftermarket parts and solutions is not merely a time and cost-saving measure; it is a future-oriented, strategic approach to delivering superior service. These components combine durability, innovation, and adaptability, enabling workshops to meet diverse customer needs while maintaining efficiency and profitability. By prioritising reputable aftermarket solutions, workshops can build trust with clients, and ultimately thrive in an ever-evolving industry.