The effects of lockdown and warmer months mean air conditioning (A/C) servicing could soon be in hot demand. Delphi Technologies’ technical advice will help technicians keep their cool in the rush.

Long-term inactivity as a result of lockdown has had a detrimental effect on brakes, batteries and tyres, but with the warmer months now edging into sight it’s soon going to be evident to many drivers that the lack of use has also impaired their vehicle’s A/C systems.

For technicians, Delphi Technologies has compiled comprehensive servicing advice, as well as some of the most common issues associated with A/C failure.

Lack of lubricant

One of the most common causes of A/C failure is a lack of lubrication. This can happen when there’s a refrigerant leak in the system from either a hose, O-ring, compressor, condenser, or evaporator. Whilst most vehicle manufacturers are now factory installing dye in their A/C systems because access is much tighter in modern vehicles, detecting leaks can be tough.

If dye is already included, inspect the system with a detection light. Even if the system is empty, the fluorescent glow should remain at the source of the leak. Otherwise, dye will need to be mixed into the refrigerant oil and added to the system to identify the culprit. Technicians just need to remember to use a dye compatible with the system they are working on. Also, today’s systems are very sensitive to oil overcharge, so care must be taken not to overfill the system.

Oil and lubricant balance

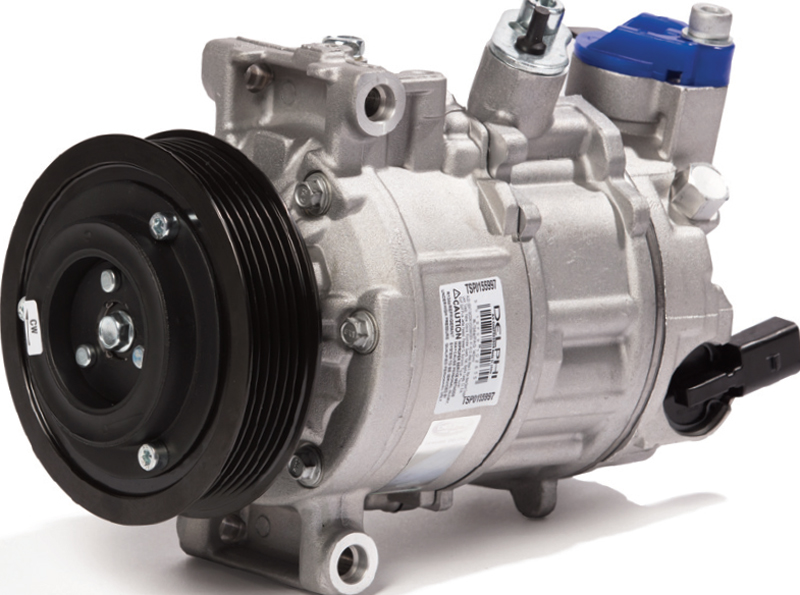

A second common cause of A/C failure is if a newly installed compressor is not oil-balanced with the correct type and amount of lubricant. When installing a compressor, always follow the instructions provided with the part, or in the vehicle’s service manual.

Technicians should also rotate the compressor clutch at least four times by hand after adding oil to the compressor. This will distribute the oil through the compressor, lubricating the components and preventing a dry start-up.

Air and moisture

Air and moisture in the system is also a threat. To operate at its best, an A/C system should contain less than 2% air by weight.

For every 1% increase in the amount of air, there will be an equivalent reduction, approximately 1%, in cooling performance. More than 6% air can cause a noticeable decline in cooling performance, and worse still, potentially lead to the evaporator freezing-up. To avoid this, technicians should vacuum the system for a minimum of 45 minutes prior to recharging. Failure to do this can lead to moisture and oil reacting, making the oil acidic – this leads to corrosion and premature failure of the system.

Best to ensure regular service

While there’s no set period for maintenance components, it’s critical to service them regularly. Take the receiver drier as an example; when the system is exposed to the atmosphere it can very quickly become saturated from humidity in the air. If this occurs, the desiccant is no longer effective and will not provide future protection. It should be replaced every time the system is opened, and as a minimum every two years.

Cabin filters can also become easily clogged, reducing the effectiveness of the filter, and in turn the performance of the heating and cooling system. To prevent this, filters should be changed every 12 months, or six months if a vehicle is mainly used within urban areas.