Varta discusses the ongoing relevance of the 12 V battery in EV vehicles.

Did you know, as well as start-stop and ICE vehicles, nearly all EVs (BEV, PHEV, FCEV, hybrids) require a 12 V power supply. As cars become more electrified and autonomous, the traditional 12 V lead-acid battery is taking on a new and challenging responsibility as a critical source of power across the evolving range of EVs.

There are an increasing number of electrified vehicles entering the market to support governmental targets of reducing CO2 emissions. Their emergence has intensified low-voltage power demands and is continually redefining the role of the 12 V battery. Enhanced levels of vehicle electrification have driven the 12 V battery to become a safety critical component, particularly if the high voltage battery fails.

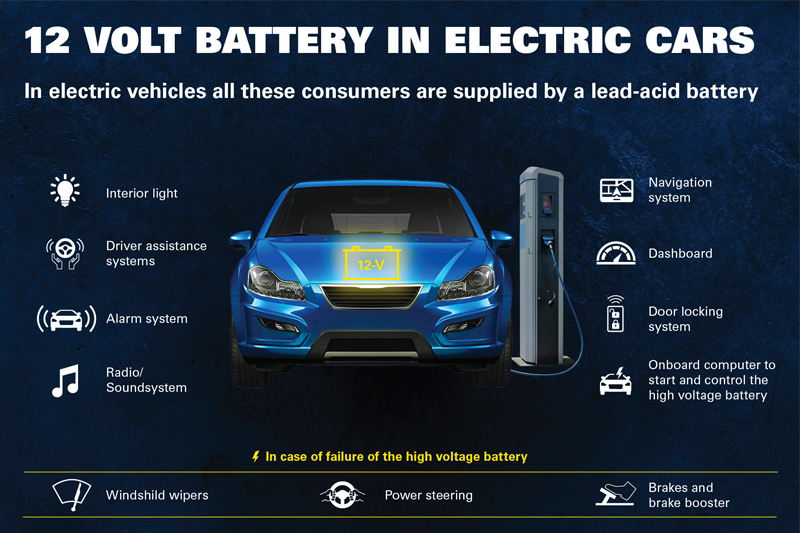

An electric car’s high-voltage Li-Ion battery powers the drivetrain and the propulsion system, however not the whole vehicle and not all of its electrical power devices. The internal electrical 12 V power system with its comfort and critical safety features, is powered by a 12 V battery. It works as a secondary power source for the vehicle’s electrical system and ensures that the car maintains its functionality while driving but also whilst parked and the high-voltage battery is disconnected from the drive train.

Comfort and safety features like lane assist, power steering and the brake booster are handled by onboard smart systems which also draw power from the 12 V system. The same goes for most of the car’s monitoring functions, it is therefore essential that a reliable 12 V power supply is in good working order.

Traditional technology

Why is lead-acid technology still being used in a modern electric vehicle?

Lithium-ion technology is often considered the successor of lead-acid technology when it comes to batteries. However, it is not as inherently robust as other battery technologies and requires continuous monitoring by the battery management system. Overall, it is a very sophisticated technology.

Lead-acid batteries, on the other hand, are known to be both reliable and affordable. Their wide operational temperature window intrinsically enhances the operational robustness of the entire system. The safety record of lead-acid batteries makes them invaluable for Europe’s future low-emission mobility sector, plus lifecycle analysis of a vehicle’s environmental impact show that lead-acid has a lower impact compared to other technologies.

“It is safe to say that the unique benefits of lead-acid technology will be important to meet growing consumer expectations for safety, comfort, and connectivity,” says Dr. Christian Rosenkranz, from Clarios, the parent company of the Varta brand.

What makes Varta’s AGM batteries many OEMs’ choice for EVs?

Varta’s absorbent glass mat batteries have proven their reliability for many years. It is their sturdy construction, behaviour and inherent safety that makes them the perfect companion in supporting the 12 V electrical system of EVs.

Every major car manufacturer is entering the electric vehicle market with battery electric or hybrid electric vehicles. As the world’s leading battery manufacturer, Clarios is the number one supplier to all renowned original equipment manufacturers with its Varta brand. Its products are fulfilling all OE requirements. That is why well-known manufacturers such as Mercedes, Volkswagen and BMW are fitting their cars with Varta batteries; in fact over 60 per cent of new vehicles in Europe are being factory fitted with a Varta.

The Varta Silver Dynamic AGM portfolio is designed to be ready for EV and hybrid vehicles, now with added designation to the AGM labelling.