Carwood is urging garage owners to switch themselves on to the potential offered by high-voltage battery repair.

As the transition to electric vehicles continues apace, independent garages face a growing risk of losing yet more business to VM dealer networks due to a lack of high-voltage expertise. With Bosch’s new high-voltage battery repair programme, Carwood is intent on reversing this trend; allowing non-EV qualified workshops to add EV battery capability and tap into a new revenue stream, with minimal risk.

With approximately 1.3 million battery electric vehicles (BEVs) on the UK’s roads at the end of 2024, and over one fifth of new car registrations now electric, the shift to zero-emission vehicles is clear. Although still largely driven by fleet adoption, this represents a growing opportunity for the IAM.

And as EV adoption grows, so too will the demand for high-quality, affordable EV servicing. Whilst there are arguably fewer items that require servicing in an EV – an electric motor has only a handful of moving parts compared to hundreds in an ICE powered vehicle – there are several high ticket items. One of these being the high voltage battery. Indeed, a new battery can cost from £2,000 to £20,000, a sizeable chunk of an EV’s total value. This also makes it a highly lucrative opportunity for independent garages – think of it an engine, gearbox and fuel tank in one – a job you won’t want to miss out on.

Breaking the VM monopoly

Until now, this opportunity has largely been satisfied by the VM dealership network due to the complexity of HEVs, a lack of qualified independent garages, and few, if any, viable service options; either replacing the complete battery pack, which is both inefficient and expensive, or replacing only individual faulty modules, which risks compromising the batteries performance and lifespan.

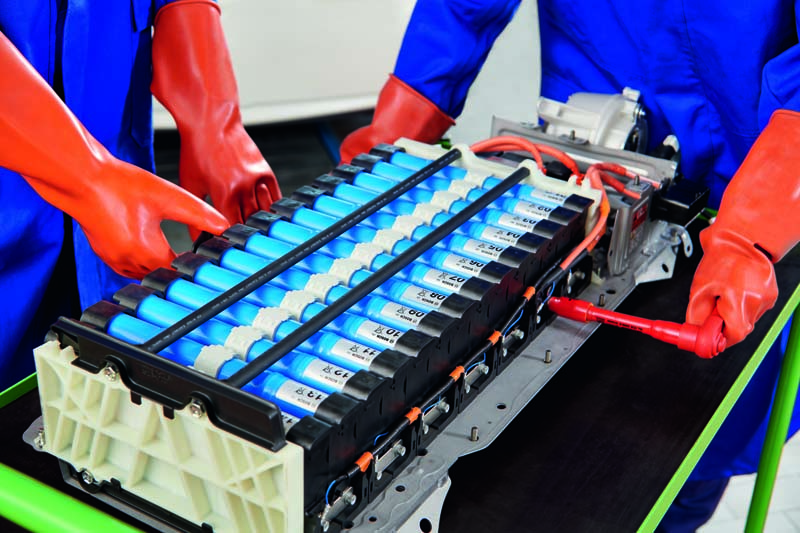

To ensure the IAM can tap into this revenue stream, Carwood has launched high voltage battery repair for Toyota Yaris, Prius, Auris and Lexus CT. Using Bosch’s OEgrade solution, our EV trained technicians can swap out all of the old modules with brand new nickel metal hydride modules.

Each module is voltage and capacity matched, just like in a new battery pack, ensuring better capacity, faster charging and a longer battery life. By replacing all modules, instead of just faulty ones, it also helps to eliminate the risk of voltage, internal resistance and state of charge imbalance, that comes from mixing old and new modules.

Because Carwood reuse all other functional components such as the housing, fan and electronics, the solution saves money and valuable resources. A repaired high voltage battery from Carwood costs on average 25 per cent less than a new unit, whilst preventing otherwise good parts from going to landfill. So you’re saving, you, and your customer, money, and at the same time, doing your bit for the planet.

The repair also meets OEM-equivalent safety, performance, and durability benchmarks, and is approved by the UK Road Vehicles Regulation. This avoids the need for additional checks post repair, saving you time and hassle too. By partnering with an EV battery repairer, independent garages without the necessary training and skills can still position themselves as an EV-capable workshop without having to handle the repair themselves in-house.

To take advantage of this opportunity, either refer the vehicle to our Coventry workshop, or if you’re qualified to do so, remove the battery and send it to us to repair locally – we can arrange a free collection and delivery and have an as-good-as new battery back to you within 48 hours.