With the help of MS Motorservice, PMM provides some insight into the electric fuel pump, and the failures that may occur with this sometimes tricky component.

The reduction of emissions in passenger cars dominates public discourse, and there is increasing demand for the use of alternative drives. From an environmental perspective, repairing vehicles which have already been produced is likewise a useful option – after all, this saves the most resources. This particularly applies to the increasingly complex and precise fuel system on a car. Here, ultimately, fuel can only be reliably supplied, precisely dosed and combusted under the condition that the individual components are fully functioning. From the perspective of performance and avoidance of emissions, damage should therefore be quickly repaired.

In this regard, MS Motorservice offers a portfolio of repair solutions. The company provides fuel pumps, pump modules, sender units, system-pressure regulators, non-return valves, regeneration valves and canister purge valves from the Pierburg brand to the aftermarket. Pierburg fuel pumps, for example, have been meeting high quality standards of vehicle manufacturers for decades. Motorservice has approximately 400 of these fuel pumps and fuel delivery modules – which are used in almost every make of vehicle – in its product range.

Useful specialist tools

However, there may be various causes for malfunctions in the fuel supply area. This is why experts initially recommend checking the fuel pressure and fuel flow.

Motorservice has assembled a test kit especially for this purpose; it allows the flow rate to be measured without having to remove of the fuel pump. Be it blocked fuel filters, fuel filter sieves or lines, faulty fuel pressure regulators, fuel pumps or fuel non-return valves, leaking fuel in-tank modules, or much more, the fuel pressure test kit makes inspection a great deal easier for the repair shop. In the case of damage to the fuel lines, there is likewise a suitable repair kit for this available from the spare parts supplier. It has most common connections for fuel filters, fuel pump connectors and fuel pumps, as well as pipe sections and pipe connectors, including refill packages.

Demand based and gentle

There are also suitable control units for fuel pumps for modern engine management systems. In the case of an unregulated fuel supply without control units, the fuel pump always delivers at maximum performance in the fuel tank. As a result, excess fuel flows back into the fuel tank via the return line. With regulated fuel supply on the other hand, the fuel pump is triggered by the fuel pump control unit with a pulse width modulation signal (PWM signal). Thus, demand-based fuel feed, with its significantly lower energy consumption, is a development which further enhances the efficiency of modern engines.

Electric fuel pumps – blocked pre-filter

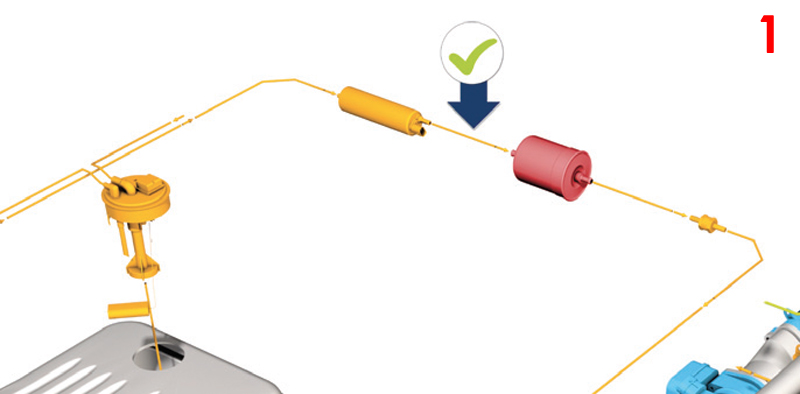

Most electric fuel pumps are flushed by the fuel, lubricated and cooled in the process. In the event of restrictions or blocks on the intake side, there is quite a high risk of dry running, which can very quickly lead to damage to the pump system. This explains why the fuel filter is always on the thrust side of the fuel pump, which results in the filter being located in the direction of flow behind the fuel pump (Fig 1).

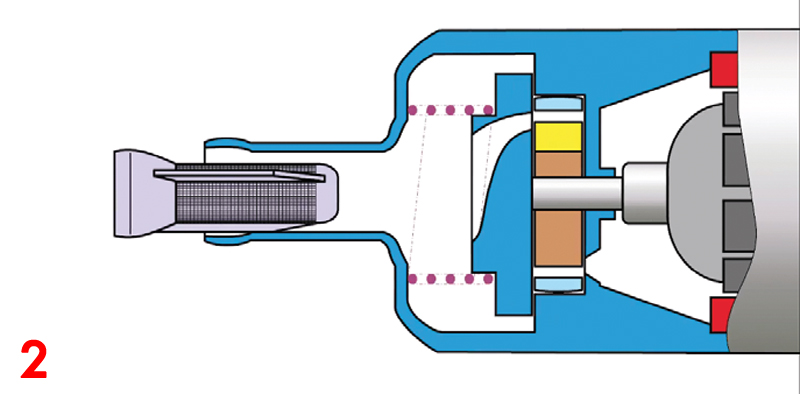

Many inline fuel pumps have a separator installed on the intake side (Fig 2). The separator provides protection from impurities, but if it is blocked by excessive dirt in the fuel, there is a risk of dry running here as well. This causes excessive operating noise and significant warming of the pump, followed by loss of power and engine misfires.

It is important to note that the separator is not available as a spare part, however, it can be cleaned, as long as this is done carefully (Fig 3). Make sure you observe the safety regulations concerning the handling of fuel when you are cleaning the separator.

Motorservice also offers a special C-filter that can be installed before the fuel pump to protect the pump from dirt and foreign particles. The same also applies for in-tank pumps. Here, too, the externally mounted Cfilter can become blocked.

About MS Motorservice

As a sales organisation for Rheinmetall Automotive’s aftermarket activities, MS Motorservice acquires a large proportion of its range internally from within the group, including the subsidiaries Kolbenschmidt and Pierburg. The internationally active spare parts specialist also has the know-how of a large international automotive supplier, which means customers benefit from products of OE quality.