Straightset provides some advice for readers considering installing or upgrading their MOT equipment.

The MOT Bay is one of the most used bays in a workshop, having the right equipment, located in the right place to allow for efficient MOT testing provides many advantages for the mechanic and garage as a whole.

Whether you’re looking to replace an existing MOT bay or build a new MOT bay, the most important starting point, according to Straightset, is the design. Speaking to specialist teams who know the rules and regulations around DVSA requirements is advisable to ensure your MOT bay is fit for purpose and gets the approvals it needs to be operational.

Starting from scratch

Installing into a new build is generally an easier process, as there is a blank canvas to work with as long as you involve garage equipment specialists early enough in the project so that key decisions and discussions can happen with architects to ensure the layouts are right and meet the DVSA requirements. Full CAD and 3D designs can be drawn up to bring the project to life.

Using an existing workshop

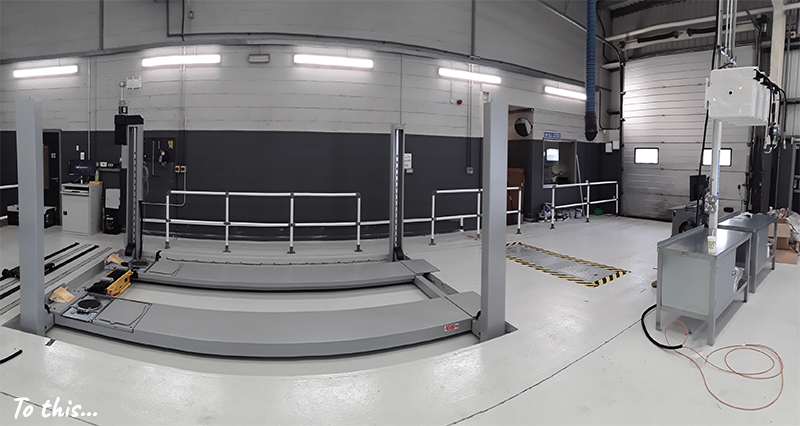

Installing into an existing workshop can prove a bit more of a challenge, but this is where the specialist skills and service of a knowledgeable garage equipment company comes into play. Starting with a detailed site survey, and analysing what existing equipment the customer already has, then discussing what the customer would like to achieve with the new bay, all whilst meeting current DVSA regulations. Utilising a design team offering CAD drawings, the replacement MOT bay can be worked out to ensure minimal disruption to the workshop.

Choosing the right equipment

There are key pieces of equipment required in an MOT bay and some of these have specific requirements to meet according to the DVSA. The main equipment that is required for an MOT bay typically includes:

- An MOT lift – with the required lifting capacity for the range of vehicles you are likely to test. With so many variations available depending upon what class you are offering, whether you want a 4-post lift, scissor lift, one for just ATL or ATL combined with wheel alignment. The Italian manufacturer Space offers a range of MOT lifts to suit individual requirements. They are robust and meet the safety standards required and with ranges available in a narrow design to fit into existing spaces or maximise the space available.

- A jacking beam – again with the required lifting capacity for the range of vehicles you are wanting to test. With variations which are manually operated or with pneumatic operation. Majorlift offers a simple, safe and compatible range of jacking beams.

- A connected and approved brake tester – there is a list of approved brake testers, ensure the brake tester you are installing is approved and can be connected. Brake tester beds come in a variety of size; if you are replacing an existing brake tester consider one with the same recess as the existing bed which will have significant savings on building works and minimise disruption to the workshop, such as the BM brake tester which fits into most existing recesses. If you are looking for a brake tester in a new build, the Capalec brake tester is a well-built, affordable choice.

- A headlight tester, such as the Tecnolux headlight tester which is DVSA approved for all classes including H.G.V and rotating column with mirror visor for accurate alignment to vehicle.

- An emissions analyser with Euro 6 compliance and MTS connectivity. There are significant advantages of a combined gas and smoke analyser like the British- built combined petrol and diesel emission analyser with the latest software, integrated oil temperature and unique RPM measurement technology.

- An MOT accessory pack with all the required tools needed to perform an MOT, which includes brake pedal depressor, mirrors, signage, pry bars, wheel chocks and more. Having a pack which has all the necessary tools rather than having to individually buy each piece, will ensure you are ready to start work on your MOTs.Above all choose MOT equipment that you can maintain efficiently once its installed. Make sure you choose equipment where spare parts can be easily accessible should you require and ask questions around whether equipment is code locked which only permits certain companies to calibrate and service equipment. Having a preventative maintenance contract on your equipment will protect your investment over time.

Straightset is a family-ran garage equipment company with over 35 years’ experience in supplying, installing and servicing garage equipment. Straightset is not owned by a manufacturer or group, therefore is able to offer choice and flexibility with the range of equipment they offer, working with leading manufacturers such as Space, Slift, BM Autoteknic, Capalec, Majorlift, Premier Diagnostics, HPA-Faip, Supertracker, HPC.