Shaftec believes that the key to its success in manufacturing parts best suited to the vehicles of the future is its continuous monitoring of industry trends – specifically those relating to the environment and fuel economy. PMM gets the full story.

Shaftec claims that the business has seen a 59% increase in the sale of its electric steering rack and column parts since 2014. Furthermore, the supplier advocates being mindful of ‘living’ these changes, by adapting business models accordingly and investing in the latest generation of machinery and testing equipment – such as its brand new diagnostic apparatus which completes a ‘real life simulation’.

This increase in Shaftec’s production is right in line with global demand. The Global Automotive Power Steering Systems market registered revenue of $17.16 billion in 2015 and is expected to touch $41.24 billion by 2020. The market for electric power steering (EPS) constituted over 50% of the overall power steering market share and this is expected to reach over 70% by 2025 due to shift from the former technology to the EPS systems.

In the past 20 years, the market for EPS systems has gradually surpassed that of conventional hydraulic steering. Increasingly, we’re seeing the replacement of traditional hydraulic pumps with electric motors and a change in design of steering pumps – from traditional hydraulic designs to electro- hydraulic power steering (EHPS) pumps. The design of the electrical component over the hydraulic offers advantages such as less weight, less maintenance, better response at different speeds, higher durability and lower fuel consumption.

Because the vehicle manufacturers have moved in this direction, it stands to reason that the aftermarket has and will continue to follow in their footsteps. Unstable fuel prices and more commonplace safety features such as electronic stability control and ABS integrated with electronic steering systems are also fueling market demand.

But it’s not enough to simply be aware of the ever shifting trends in automotive technology, as Chris Journet, Shaftec’s UK Sales & Marketing Manager, says: “To prosper in an increasingly competitive market, you have to actually put your money were your mouth is and replicate these changes within your own business model.

“That means constant research, ongoing market evaluation and investment to ensure you retain as much control of material, testing and manufacturing processes as possible in order to stay ahead of the game. In addition to this, knowledge is power when it comes to steering systems. The better you know your product, how it operates, its features and benefits, together with how to maintain it, the better equipped you will be to assist your customers – and in turn they can better assist their customers with advice on components.”

Know your steering stuff

The steering system consists of several items: a rack and pinion connected to the front wheels; a piston inside the rack and pinion, which is moved by pressurised fluid from the power-steering pump that helps to turn the wheels; and a cylinder containing fluid mounted on the pump or remotely mounted for easier access. If there isn’t enough fluid, steering becomes more difficult and parts can become damaged. Low fluid levels can also be the first sign of a bigger problem as it may indicate a leak and for everything to work as it should, the fluid level should never drop. It’s therefore vital to regularly check power-steering fluid levels and top up when necessary. And remember, pumps and racks will live longer if the system is flushed regularly.

She’s electric

EPS works like this: to provide steering assistance, an electric motor mounted to the side of the rack housing drives a ball-screw mechanism via a toothed rubber belt. The screw engages a spiral cut in the outside of the steering rack. A torque sensor attached to the pinion shaft signals to a control computer when to provide assistance.

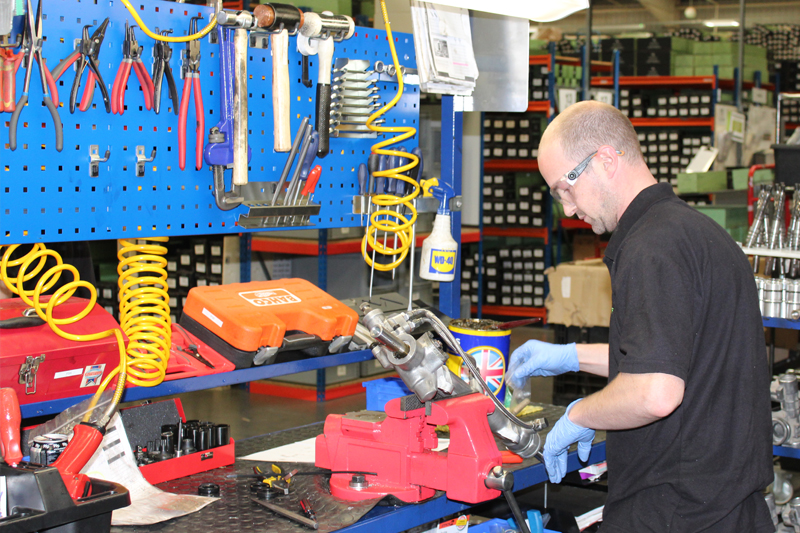

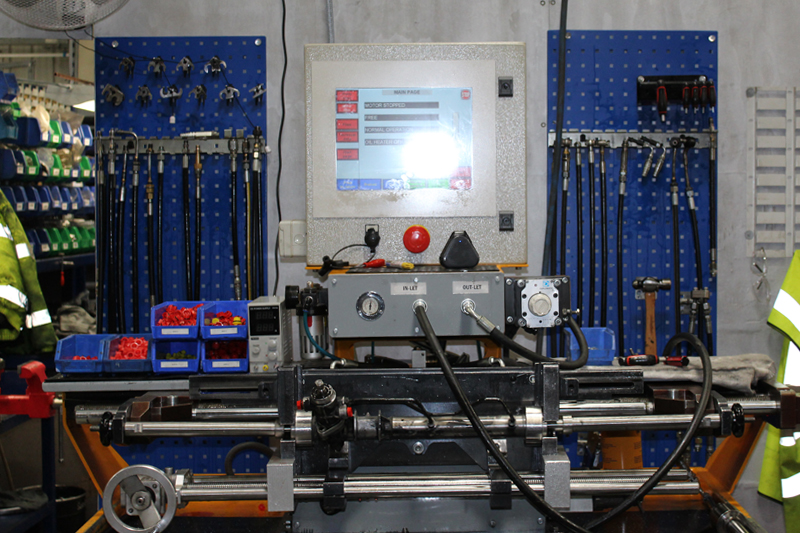

Chis continued: “We invest back into the business in terms of infrastructure, manpower and machinery. The latest addition is a state of the art piece of diagnostic equipment that completes a ‘real life simulation’. This tests steering racks as if they were fitted to a car being driven. By allowing us to check the torque sensors and steering angles, clear fault codes stored in the ECU, and assess the assistance the rack is giving at different speeds (as they are speed variable) it provides a much clearer picture of the components’ ability to react to real life situations.

Furthermore, as many electric racks are individually imbedded with the vehicle chassis number and unique identity, this equipment allows us to ‘virginise’ the unit, allowing a remanufactured component to be connected to a new vehicle and obtain its new details from the main vehicle ECU.

This means the unit can be fitted with a ‘plug and go’ ethos as long as the fault has been cleared from the main vehicle ECU prior to being fitted. The benefits of this include a bigger range of part numbers available, speedier diagnosis of faults and massively increased in-house control.”