Rotronics, the battery management expert, presents how the newly developed CPX900 can help alleviate the woes of your customers.

Motorists have certainly been going through the mill for the last year and it is vital that workshops prepare to be a source of assistance and exceptional customer service to them if there is to be hope on the horizon. Much has been written about how to best care for customers whose cars have been sitting doing little on their drives for months. Less has been written about the technology required to do that.

Developing the technology

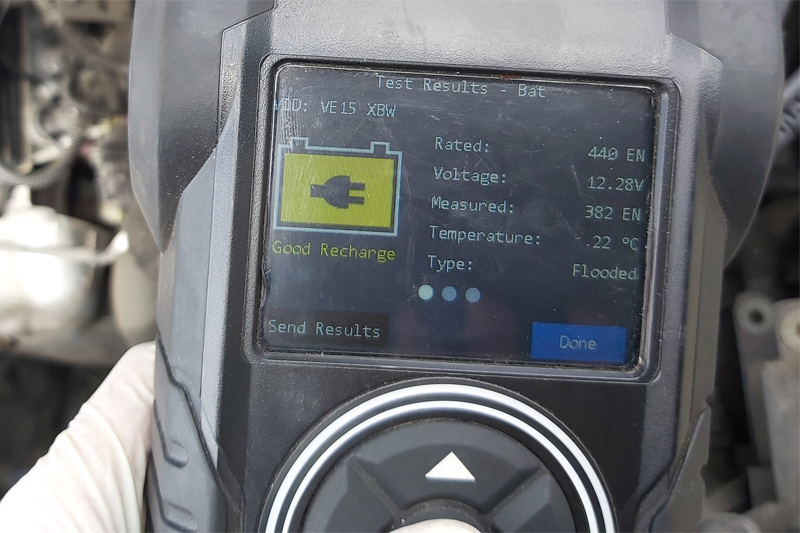

The best options for battery testing, and to ensure that your customers can receive proof of a test without being in the workshop, include the CPX900 Conductance Profiling Battery and System Analyser, which will service contemporary vehicle and battery technology showing reserve capacity (RC) problems.

The CPX900 is ideal for independent garages dealing with inspections, MOTs and servicing, and can be used at any opportunity for testing stop-start applications where the battery is integral for getting a vehicle from A-B.

Some of the product’s features include conductance profiling, WI-FI and Bluetooth connectivity, wireless updateable software, elective connectivity to Rotronics’ ROBIS Online Portal (subscription based), stop-start battery testing, electrical system tests, a built-in temperature sensor and an optional integrated printer. The CPX900 comes with either 1.1m or 3m cables; the 3m cables enable a single-handed full system test from the driving seat of the car.

Keeping up with communication

Importantly for the current restrictive climate, test results can be emailed to your customer due to the wireless interface. This provides several benefits: you have instant visibility concerning the condition of your customer’s battery; it will tell the customer if they need to replace the battery and when next to charge the battery; it will also provide an overall decision about the battery, with a full health check, measurement of the cranking ability, and status regarding the reserve capacity.

The technical experts at Rotronics have been making important changes to the existing CPX900 technology and this will be available in a more intuitive package, which is a real bonus for independent workshops and their customers.

Ken Clark, Managing Director at Rotronics, said, “This is a fantastic tester for independents, and we have worked hard over the past months on a screen layout that is much more user-friendly. We are creating some shortcuts to the testing process and modifying the software to determine why the test is being done, who is doing the test and include the workshop’s logo on the printout.

“This is an ongoing technology development and our team will be delighted to receive any feedback from PMM readers. Please send an email to me at ken.clark@rotronicsbms.com.”

CPX900: What’s included?

- The diagnostic report wording is more customer friendly

- It will recall customers at regular intervals for a battery test

- Linked to the ROBIS portal, it provides historical testing visibility

- The customer can see how the battery is performing over time

- It shows how the drive cycle is affecting the battery

- Gives workshops the ability to provide expert advice, such as:

- Recommending more frequent charging

- Additional customer service offerings

- Vehicle usage and improvements that can be made