Nissens guides the PMM audience through the replacement of an EGR valve.

Note: This is a generic installation guide, therefore some specific fitting instructions issued for a given vehicle make and model may overrule these recommendations, which is why it is also important to refer to the vehicle manufacturer’s documentation and original equipment data.

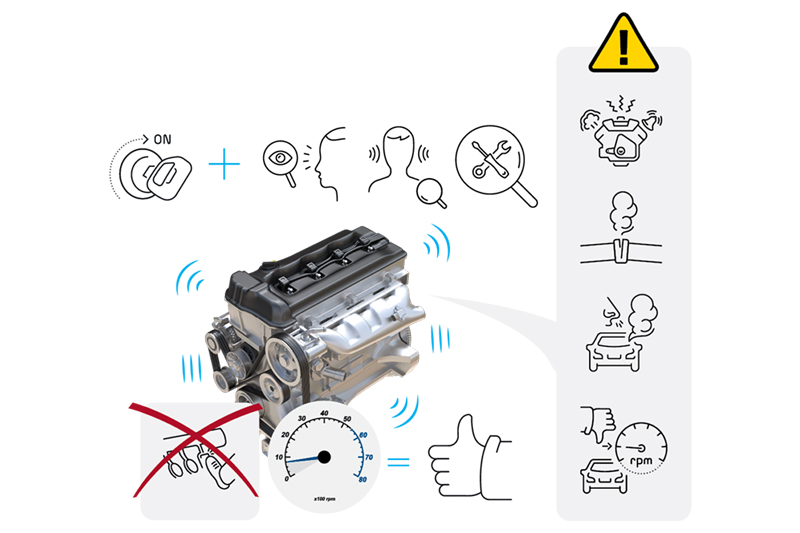

The failure of an EGR valve can provoke malfunction of the exhaust emission control and cause the failure of emission control devices such as the DPF filter, catalytic converter or turbocharger. Look out for these common signs of malfunction:

- Engine check control lighting on the dashboard

- ECU setting the engine into limp mode

- Reduced engine power

- Significant changes in fuel consumption

- Engine emitting pinging and knocking sounds

- Rough, uneven idling

- Stalling and hesitation during acceleration

- Exhaust gases escaping within the engine compartment

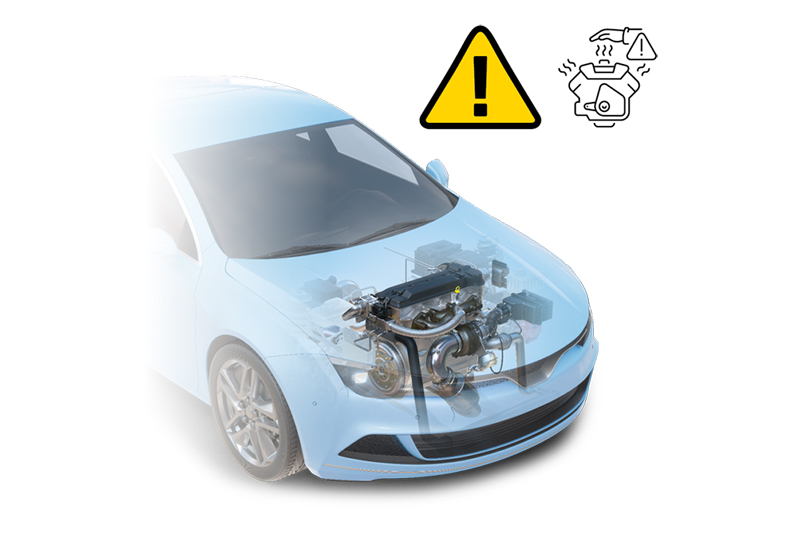

EGR valves are often located in the engine compartment and close to heat-generating components, so the valve can get very hot. Therefore, before starting the diagnosis and fitting procedure, make sure the vehicle has cooled down to a safe, low temperature level.

Understanding what can cause damage

As the valve operates in a harsh environment, under thermal stress and the direct influence of the flow of exhaust gases, there are many factors that can cause its premature failure. The following are the most common reasons and their root causes must be recognised and eliminated effectively.

1. Excessive contamination by carbon build-up

The most frequent failure is the valve getting stuck in an open or closed position. This happens because of unusually high levels of carbon deposits and the reason for the contamination must be eliminated. Typically, it’s linked to one of the following:

Improper, unclean combustion in the engine caused by:

- Improper air-fuel ratio of combustion

- Excessive oil intake/burning by the engine

- Engine overcharge

- ECU/Engine management errors including software version problems

Frequent short-distance journeys: Specifically at lower ambient temperatures, when the higher humidity of the intake air impacts the crankcase ventilation, which leads to the formation of sludge, soot and carbon.

2. Thermal stress

Excessive exhaust gas temperatures and engine overheating can cause the valve housing to crack or its inner elements to melt.

3. EGR system leaks

Leaks in the ducts and hoses of the EGR system expose the valve to abnormal working conditions and can quickly cause breakdowns.

Diagnosis

As the EGR valve is not a standalone part and operates in a system with other components a thorough EGR system diagnosis is required, particularly as most valve breakdowns are caused by factors other than the failure of the component itself.

Using dedicated tools and recommended methods, as well as by simple visual inspection, check:

- Exhaust lines related to the EGR

- Vacuum pump connection and lines

- EGR electrical connections

- EGR air connection (pressure/vacuum)

- Coolant connections to EGR cooler (If applicable)

Perform an OBD diagnostic span to specify the failures related to the valve, but remember that error codes for a specific sensor or malfunction may not reveal the root cause of the problem. Often, the errors are stored due to another problem in a related system/component, causing the inspected sensor/device to send improper readings. It is, therefore, important to analyse and recognise the real cause of the malfunction before replacing parts.

Possible OBD error codes:

P0401 Exhaust Gas Recirculation –

Insufficient flow detected

P0402 Exhaust Gas Recirculation –

Excessive flow detected

P0404 Exhaust Gas Recirculation – Circuit

Range/Performance

P0103 Air mass too high

P0102 Air mass too low

Other possible causes:

- Vacuum pump operation or its connection/ducts problems

- Crankcase ventilation system issues including PCV valve function and improper oil separation

- Tolerances within the engine inner parts (high mileage engines) causing excessive blow-by gases formation

- Turbocharger failures, specifically bearing and seals issues, blocked oil return line

- Improper engine oil filtration – worn filter, exceeding service intervals

- Improper grade/poor quality engine oil applied

- Improper oil level, mainly too high

- Wear of the valve seals/washers/guides causing excessive oil transfer to the intake port

Installation

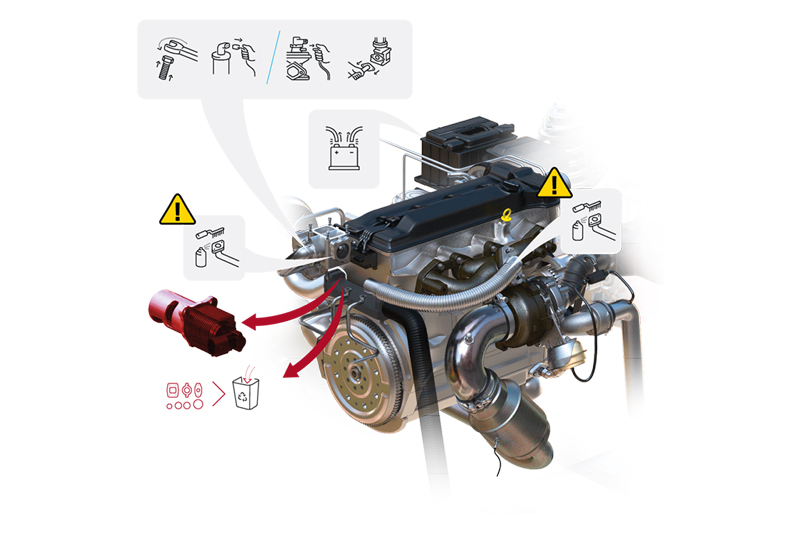

After disconnecting the battery and removing the faulty EGR valve, thoroughly clean all gasket surfaces and flanges and check the condition of the supply pipes and cables, then fit the new EGR valve as follows:

- Install all new gaskets (if applicable) for the EGR valve connections

- Fit the valve using original fixings/screws. Use a torque wrench when tightening – for information on tightening torques, refer to the vehicle manufacturer’s specifications

Note: Do not use an air impact wrench. It can cause irreversible damage to the valve mounting brackets and housing

- Reconnect electrical fittings

- Reconnect vacuum line fittings

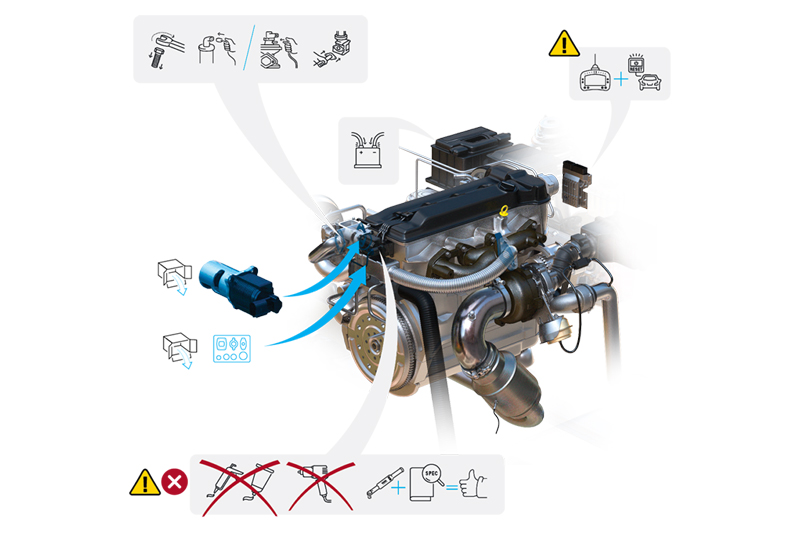

- Reconnect battery

- Reset ECU/check software version by means of an OBD controller

For some vehicle models it may be necessary to reset the ECU unit in order to clear any stored fault codes relating to the previous EGR failure.

In some cases, after installation of a new electric EGR valve, the new part may not be detected properly by the ECU and the valve will not operate, which can repeat some further OBD faults for the EGR, so it needs to be mapped. This can be performed by the ECU tester/OBD controller. For a specific mapping guide consult the device manual or vehicle technical documentation.

Testing

A. Inspect the engine operation. Run the engine at idle to warm up to the normal operating temperature of around 90°C, it should idle smoothly and evenly. Inspect for any leakages of air, exhaust gas or coolant (by water-cooled valves). If any are spotted, they must be fixed immediately.

B. Final OBD diagnosis. Perform another OBD inspection for any EGR-related errors, and examine the exhaust gases emission.

C. Road test. Finally, take the car out for a drive and check that the engine operates properly, running smoothly in all rev ranges and generates the proper power.