PMM meets Polybush, a Wrexham-based manufacturer of polyurethane suspension bushes, which came into being in the most unusual of ways.

It all started with a visit to a local Wrexham factory, where Suba the dog picked up a piece of polyurethane elastomer, which ended up being her favourite chew toy. Over time, her owner Roy noticed that the polyurethane was completely untarnished and free of bite marks, and this triggered a series of events. Roy, having worked closely with suspension bushings before, began to think, ‘if only bushes were as tough as that polyurethane – they wouldn’t need to be changed so often…’

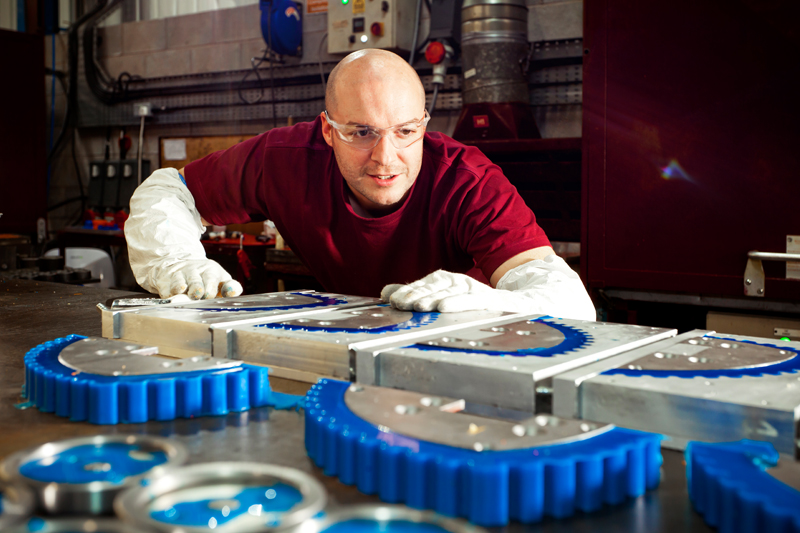

Roy approached a manufacturer – Bonaprene Products – and together they began to create polyurethane bushes that were not only easier to fit, but far longer lasting than their metalastic counterparts, with varying benefits depending on design. Very quickly, demand increased and the creation of bushes became a large operation, with many types of bushes being distributed internationally, as far as Columbia, The Middle East, Africa and India.

Due to the speedy growth of the business, Roy (and Suba) had to make the difficult decision between selling the business and cruising the Mediterranean in his yacht. At this point, Bonaprene took on the bush business in its entirety and Roy set sail to enjoy his retirement. Bonaprene kept the division separate from its own industrial activities, naming it Polybush.

The Polybush division has its own dedicated design, marketing, sales and administrative staff. The business has continued to grow over the years and says it is proud to manufacture OE products that are supplied directly into many types of industry, including commercial and retail.

Polyurethane is an ideal material for suspension bushes as it has a combination of high tensile strength and elasticity, which translates into immense durability even in the toughest conditions. As well as no perishability or wear, it will spring back into shape effortlessly to absorb huge levels of shock, making for a more comfortable ride. Polyurethane bushes require no special tools for fitment, have four to five times longer life spans than rubber bushes, and are generally easier to fit.

Polybush has solved many issues within different markets, ranging from MOT failures to costly recurring replacements on large fleets. An example of a huge cost saving is a bush that was designed for the ambulance market. The bushes were suffering premature wear due to their intense usage, but the parts required were not available separately, meaning a full ARB and spring replacement was needed on a regular basis. Polybush was able to design a bush that solved the problem of premature wear, fitted perfectly into the current ARBs, and decreased fitment time significantly. This change is claimed to have saved the NHS £700 per vehicle in parts alone.

Polybush says it is dedicated to expanding its product range, and is always working on new designs and manufacturing techniques that will save time and money in the automotive industry.