Fed up of wet timing belts failing prematurely? Become your customers’ best friend with this preventative maintenance advice from engine oil additives firm Wynn’s.

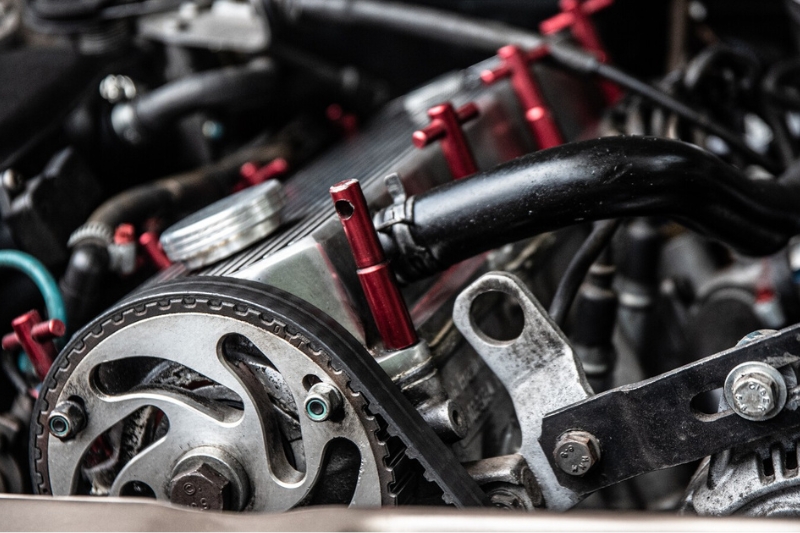

Timing belts immersed in oil are a well-known problem for any mechanic charged with maintaining them. Some of the best-known engines are:

- Ford 1.0 EcoBoost

- PSA 1.2 PureTech

- VW 1.0 TFSI

What are the benefits of having the straps submerged?

- Reduction of friction (up to 20 per cent)

- Reduction of fuel consumption and CO2 emissions

- Reduction of weight and consequently in costs for manufacturers

- Reduction of the belt maintenance interval (from 74,000 to 124,000 miles)

What are the drawbacks?

The belt immersed in oil can break down very prematurely, even before 37,000 miles. The decomposition of this belt and the dirty oil, generates a type of sludge that in many cases clogs the suction tube and other circuit components. This obstruction can cause damage that will cost at least £3,000 to fix the oil pump, and the turbo as well as replace a new timing belt.

Why do timing belts break down?

Currently, gasoline usually contains 10 per cent bioethanol. Due to direct injection, part of this fuel is filtered and ends up meeting the crankcase oil. This mixture will be in continuous contact with the belt and it is the acetic acid of the bioethanol that will cause the timing belt to break down.

How can we avoid or slow down this decomposition effect on the belts?

Keeping the engine oil as clean as possible: To do this you must clean the engine at every oil change. If you don’t clean it and add a new oil, the acetic acid from the bioethanol will still be present in the crankcase and the decomposition of the belt will continue to be provoked.

Instructions for cleaning the lubrication system and keeping the oil clean:

- Add a bottle of oil system cleaner before changing the oil into the tank with between 3 and 6 litres of lubricant.

- Maintain the idle speed for 20 minutes.

- Remove the used oil and replace the filter. Then fill with new oil.

- One 325ml container treats up to 6 litres of motor oil.

Avoid fuel leaks into the oil as much as possible:

To do this, it will be necessary to reinforce the properties of the lubricants to neutralise the acids and improve friction in the engine. For this, you will use hydraulic valve lifter concentrate.

Instructions for use:

- Add one bottle of hydraulic valve lifter Concentrate to the oil tank with between 3 and 6 litres of lubricant.

- Check that, when adding the product, you do not exceed the maximum oil level.

- One 352ml container treats up to 6 litres of motor oil.

- Use at every oil change or more frequently if necessary

Cleaning the fuel injectors is also key to reducing excess fuel entering the oil system. When the spray pattern is poor, more fuel is used. The excess fuel passes the piston rings and enters the oil system further contaminating the oil. Cleaning the injectors with Wynn’s extreme injector cleaner will restore injector spray patterns and vehicle performance.