In this instalment of the EV series Tom Denton discusses how EVs actually function.

After focusing on the motor in the last article, I thought I would outline how EVs actually work in general.

In any situation, with technologies or otherwise, an effective way to start thinking about how it works is to consider it as a standard control system. This is shown in Fig.1 as three simple blocks: inputs, control, and outputs.

Thinking about an EV as a whole, the basic inputs are:

• Accelerator (move off, speed up, cruise, slow down)

• Brake (slow down or stop)

• Other driver controls (forward or reverse for example)

• Electrical energy (high voltage battery)

The control block represents:

• Electronic control unit

• Power control electronics

The single output of this simplified system will be:

• Traction motor

To drive an EV, press the accelerator – this sends a signal to the power control electronic systems and the motor moves the car.

When the vehicle is slowed down, the motor is driven by the wheels and becomes a generator. Under these circumstances the motor (now a generator) becomes a system input and the electricity is output to the battery. This is known as regeneration or recuperation – in other words, a significant amount of braking energy is stored and not wasted as heat like with normal brakes.

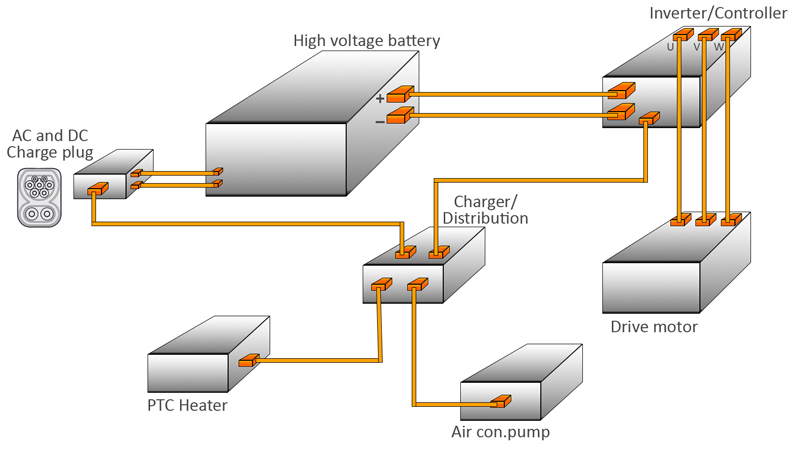

Let’s now expand the ‘blocks’ of an EV further and this is represented by Fig.2.

This shows the main EV components and the high voltage connections. The battery is typically about 400V. There are some very sophisticated electronic control and monitoring systems but the layout and components of an EV are quite simple:

• Battery (usually lithium-ion, stores the electrical energy)

• Inverter (converts battery DC into three-phase AC to drive the motor, the opposite if generating)

• Charger (converts mains electricity to a suitable value and controls charging when plugged in)

• Heater and AC (both are electrically operated on an EV as there is no other source of power)

• Drive motor (three-phase is the most efficient design, becomes a generator when slowing/braking)

Fig.3 is an example of how all these components are positioned in a vehicle. The Volkswagen ID4 is shown here. The battery takes up all of the floor area.

The rear-wheel-drive electric motor is located above the rear axle just in front of the centre of the wheels and transfers its torque to a two-stage 1-speed gearbox with differential. An all-wheel drive system is also available where an additional motor is fitted at the front. The electric drive motor weighs about 90kg. The power control systems are fitted close to the motor(s).

But remember, no matter how complex a vehicle may first look, it is only a combination of inputs, controls and outputs.