febi gives aftermarket technicians an overview of an underrated suspension component – the stabiliser bar.

The stabiliser bar is a component of the suspension and connects the wheel suspension of an axle with the body structure. Many cars are equipped with a stabiliser bar on the front axle and some of them with one on the rear axle as well.

Stabiliser bars have been installed in passenger cars for many decades and have remained practically unchanged in this time. The stabiliser bar (or anti-roll bar) is little known to many motorists, although this component plays a significant role in ensuring a safe and comfortable journey. The simple reason: Without a stabiliser bar, vehicles would overturn in corners and driving comfort would be drastically reduced when driving straight ahead as well. As a rule, even knocking noises from the suspension can be attributed to a fault in the stabiliser bar area.

Failure of, or damage to, the stabiliser bar is mostly inexpensive. This is due to the relatively low material costs and straightforward installation. But beware: If the stabiliser bar is damaged, the vehicle should not be moved. Failure increases the risk of the rolling motion of the body structure, getting out of control and the vehicle overturning.

How does it work

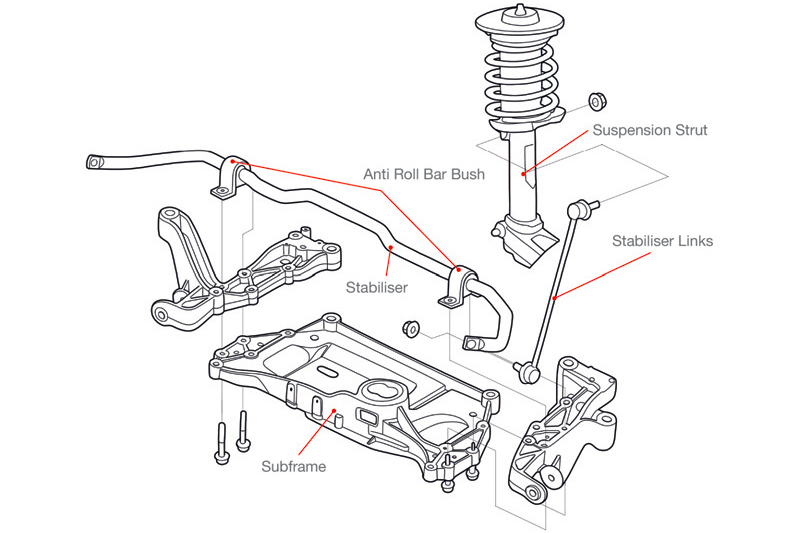

The stabiliser system also consists of other components, e.g. stabiliser links and stabiliser bearings. The stabiliser bar is mostly mounted on a subframe and in rubber bearings. The stabiliser links connect the stabiliser bar to the suspension struts or, alternatively, to the control arms. Special ball joints on the stabiliser links ensure the necessary freedom of movement to allow the stabiliser bar to do its job flawlessly.

When a wheel deflects, the torsion of the stabiliser bar ensures that the other wheel is also raised and likewise lowered upon rebound. This prevents excessive rolling (lateral tilting) of the body when cornering. If the two wheels deflect simultaneously, the stabiliser bar does not activate.

What can go wrong?

In the event of failure or damage to the system, loud knocking noises frequently occur in the suspension when driving over bumps or potholes. These are mostly caused by worn bearings or defective ball joints on the stabiliser links. In the case of worn bearings, an unintended play arises between bearing and stabiliser bar, and the stabiliser bar begins to rattle in the bearings on deflection and rebound.

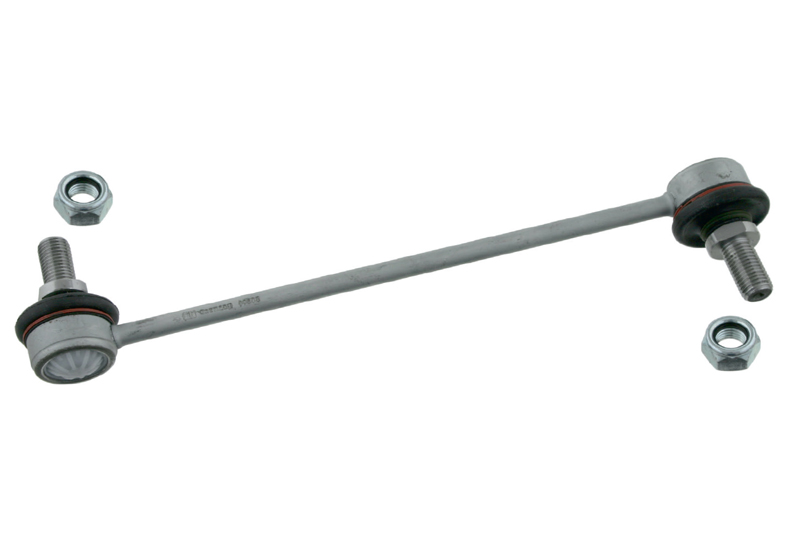

A frequently installed type of stabiliser link features ball joints that are protected by a rubber boot from spray water and external influences. They are also packed with grease to make the movement as frictionless as possible. Every now and then, the rubber boot or the associated seal is damaged. This allows water to enter and provides for unnaturally high wear. The consequence: too much play in the joints, which leads to the noises mentioned above.

When replacing the stabiliser link, it must always be ensured that the correct torque is applied during installation. Otherwise, the ball joint can be damaged, wear prematurely or even break off.