The lifetime of a compressor is only guaranteed when the correct amount of recommended oil is used. If contaminated by foreign oil or additives, such as the wrong or too much UV dye, the refrigerant must be flushed before new parts are installed, as Denso explains…

A compressor is lubricated by oil, which mixes with the refrigerant gas R1234yf – or R134a if the vehicle was built before European Union legislation came into play. When the vehicle starts up, it forces the refrigerant gas and oil mix around the system. As the mixture flows around the system, oil coats the inner surfaces of the pipework, condenser tubing, and remaining components. The remainder is for lubricating the compressor while in operation, which relates to decanting the new and old compressor.

A replacement compressor supplied by Denso contains the correct amount and type of oil for the entire system – half of the oil remains lining the pipework, condenser tubing and remaining components. The remainder is used to lubricate the compressor while in operation.

When technicians check for leaks, only 3-5cm3 of UV leak dye should be added to a system containing up to 1kg of refrigerant and 2cc, for a 500g system. However, it can only be added once, as too much would degrade the lubricative quantities of oil.

When does the system need flushing?

The nature of the repair dictates whether flushing should be carried out – when flushing is necessary, it is, in essence, cleaning the system.

The flushing process uses refrigerant in liquid form – liquid is eventually compressed into gas. However, Denso’s philosophy is that where metal particles are suspected to be present and contaminating the system, following catastrophic internal compressor failure, for example, best practice is to change the entire system, as flushing will not guarantee the removal of those metallic particles.

When flushing, technicians should use dedicated flushing equipment and correct type of refrigerant, without using an air conditioning service station.

Installation tips

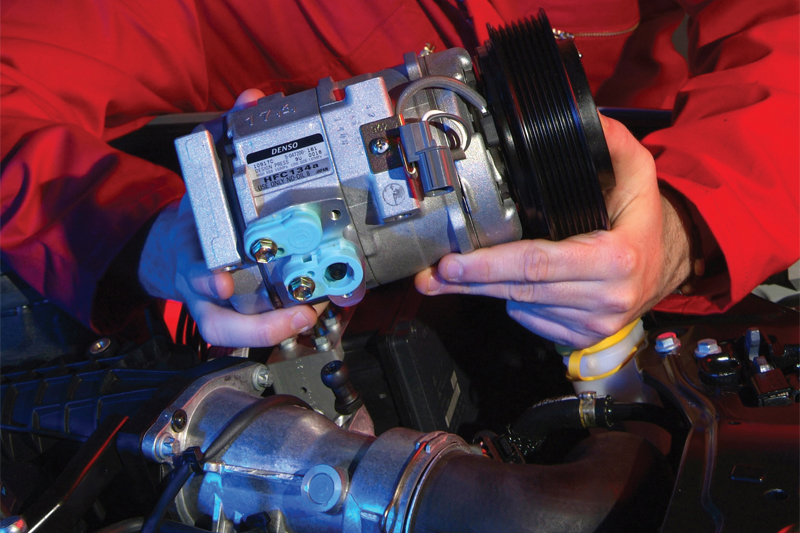

If the system has been flushed, the Denso compressor can be installed directly. Turn the compressor systematically by hand to distribute oil evenly – this will avoid damage during start-up.

For some applications, it is necessary to add oil; for example, when single and dual evaporator cycles have the same part number, or when the oil quantity of the new compressor differs from the vehicle specifications. If this is the case, technicians should check the data from the vehicle manufacturer to confirm the correct oil amount. However, oil should never be added to the compressor – it should always go into the condenser, receiver dryer or second evaporator cycle.

Technicians are urged to stick with Denso’s recommended oil type, ND-oils, and are advised never to mix or use a ‘universal oil’, as doing so likely shorten the life expectancy of the new compressor and cause severe damage. Denso will refuse a warranty claim if an investigation proves that there was contamination. After installing a new compressor, it is essential to ‘run it in’, the purpose of which being to distribute the oil and start up lubrication to prevent damage after the new component is fitted.

Procedure

Set the temperature to ‘max cool’ and switch blower to ‘max speed’. Then start the engine and maintain engine RPM at ‘idle’. Switch on the air conditioning for a minimum of five minutes without increasing the engine speed. After five minutes, the compressor oil will have travelled around the system thoroughly. Only after conducting this procedure is it safe to increase the engine speed and test the air conditioning.

Oil distribution

If flushing is not required, technicians should use the following calculation to determine the correct amount of oil to drain from the new Denso compressor:

C = A – B

A = Total amount of oil in new Denso compressor

B = Amount of oil drained from the old compressor

C = Amount of oil to remove from the new compressor

The total amount of oil in the new compressor (A) is 120cm3. The total amount drained from the old compressor (B) is 50cm3. The amount of oil to remove (C) from the new compressor is A-B (120-50 = 70cm3).