Air/fuel ratio sensors and oxygen sensors – what’s the difference? Denso has the answers for PMM.

Despite the rise in popularity of pure electric powertrains, vehicle manufacturers (VMs) are still under intense pressure to improve the ecological performance of their combustion engines to comply with evermore strict emissions targets. As a result, monitoring the engine’s exhaust emissions takes centre stage and the air/fuel ratio sensor is a special type of oxygen sensor that can support more sophisticated emission control processes.

To comply with current and future emissions targets, engine management technology never rests, as original equipment (OE) component manufacturers such as Denso, continue to develop more sophisticated sensors to satisfy the needs of the VMs. As a result, the trusted oxygen, more commonly referred to as Lambda, sensor has had to be supported with the addition of many other sensors, including air/fuel ratio sensors.

The differences

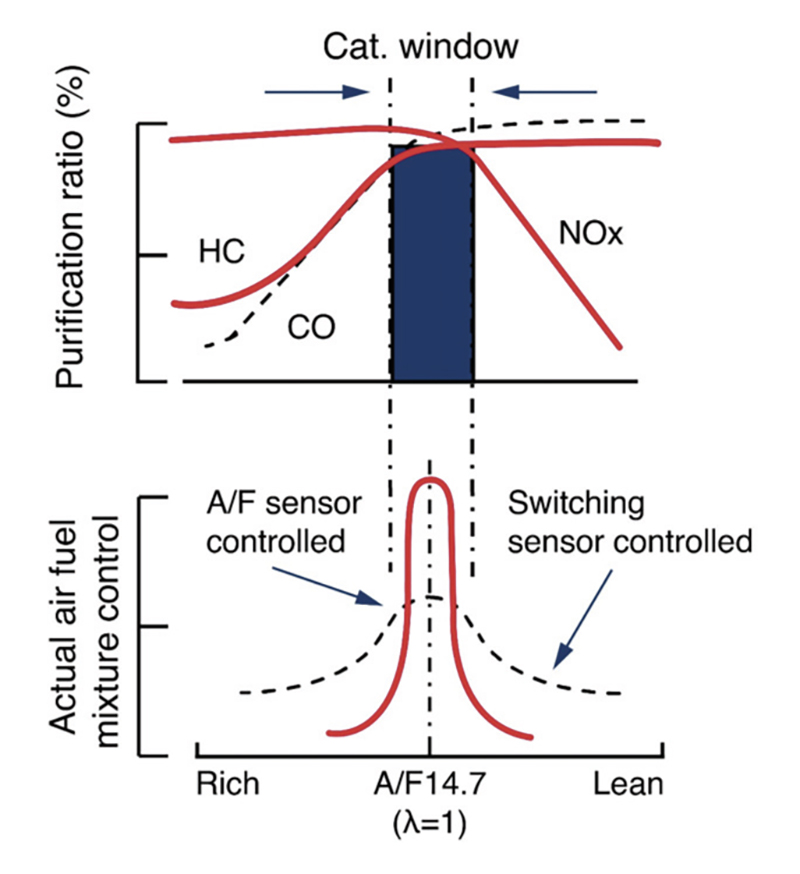

Although both these sensors serve a similar purpose – to monitor the exhaust gases and communicate this data to the vehicle’s engine management system (EMS), to optimise the fuel and air mixture coming into the engine’s combustion chambers, as well as the engine’s ignition timing etc. – the air/fuel ratio sensor provides a higher level of sensitivity than the traditional oxygen sensor. This allows the EMS to respond to the needs of the engine with higher accuracy, which enables the fuel to burn more efficiently, therefore producing lower emissions and increasing the vehicle’s fuel economy.

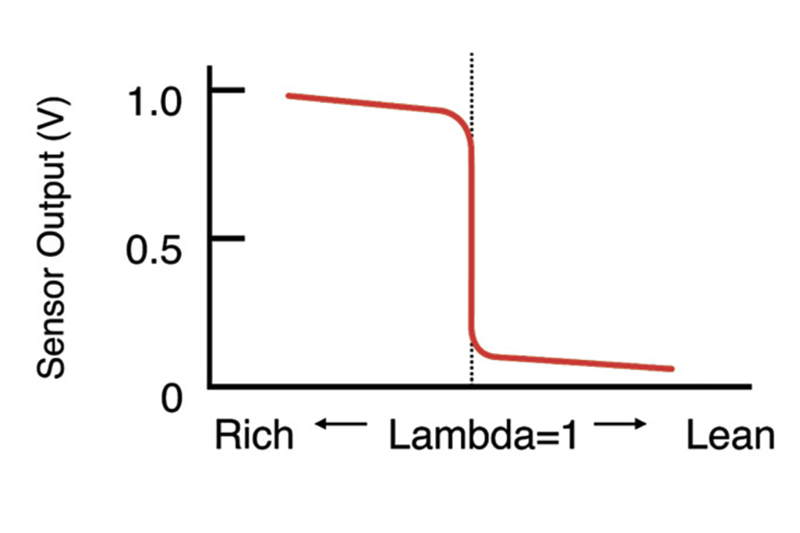

This difference in sensitivity can be demonstrated by the fact that the oxygen sensor produces a voltage signal that suddenly changes on either side of the ‘Lambda ratio’ – defined as 14.7 parts air to one part fuel, which is the most efficient air/fuel mixture for a combustion engine – 0.8 volts if the mixture is too rich or 0.2 volts if it’s too lean.

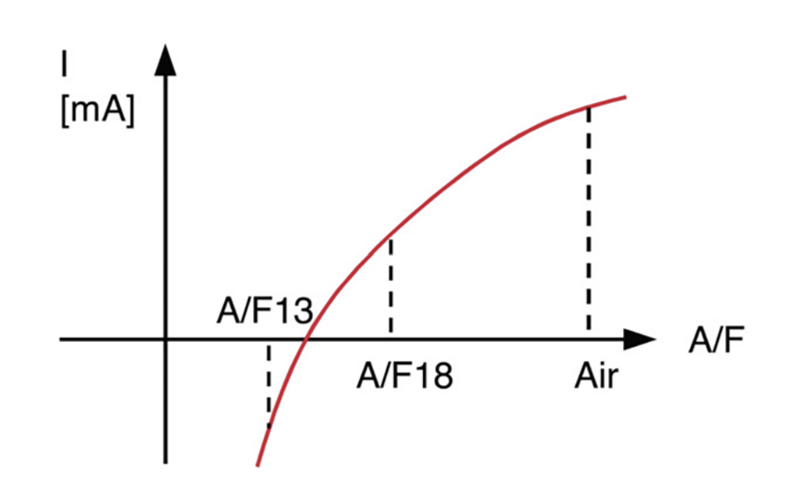

In contrast, the signal output of an air/fuel ratio sensor is not a voltage, but a current. This current, measured in mA, changes in proportion to the amount of oxygen left in the exhaust gases. In other words, the ECU (engine control unit) can understand, not only if the mixture is rich or lean, but can also precisely understand by how much.

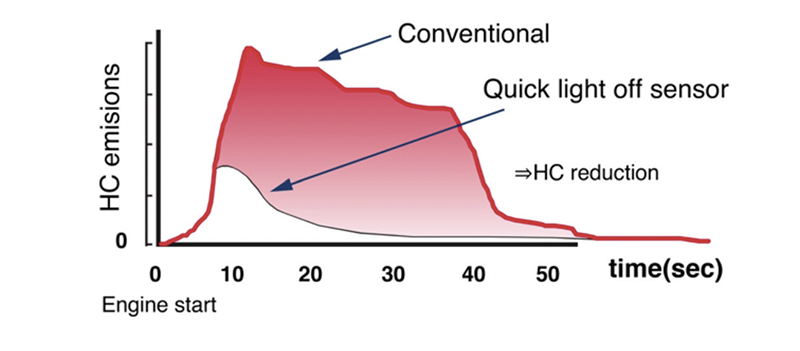

This quantitative measurement allows the EMS to respond to the immediate air/fuel mixture requirements of the engine more quickly and accurately. This provides a greater degree of control over the combustion process and the efficiency of the catalytic converter can be improved significantly as a result. Also, in case of a cold start, the engine can reach a closed loop control much quicker, which reduces the emission of unburned hydrocarbons.

It goes without saying that the signals that these two types of sensors produce are very different from each other, therefore, they cannot be exchanged. In fact, there are many different varieties of air/fuel ratio sensors. Some differences are visible from the outside, whereas others vary electronically, but most differences are hidden inside the composition of the ceramic recipe or the protection coatings on the sensor’s elements. Therefore, it is very important to always choose the exact same original design specifications, when replacing an air/fuel ratio sensor.

Denso has recently witnessed a few examples of imitation sensors appearing on the market and its laboratory and vehicle tests of these products have revealed very poor performance levels and lifetime, as well as over-consolidation of vehicle applications, which would certainly lead to premature failure and re-occurring engine warning lights on the dashboard should they be fitted to a customer’s vehicle.