During a period of rapid change for Europe’s automotive industry, and coinciding with its 125th anniversary in 2024, Castrol decided (for the first time) to provide an exclusive insight into its Driveline Technology Centre (DTC) in Hamburg-Neuhof in Germany.

This, otherwise closed for public, research and development facility is where Castrol develops and tests ‘EV fluids’ for current and future electric vehicles, in addition to gear oils for cars with internal combustion engine..

The global shift towards electric mobility opens up numerous opportunities for Castrol to take a lead in the development and supply of specialised high-quality lubricants and other technical fluids formulated specifically for plug-in hybrids and full battery electric vehicles. The DTC is where these fluids that are critical for the safe and efficient operation of future EVs are formulated.

A century’s progress

The rigorous test and development of lubricants by Castrol dates back to 1899, when Sir Charles ‘Cheers’ Wakefield founded CC Wakefield & Co. Limited; the company that became Castrol as we know it today. Early in the 20th century, the Wakefield business began developing lubricants for automobile and aeroplane engines; a range of products that were runny enough to operate effectively from cold at start-up, but also thick enough to keep working at very high temperatures. Wakefield researchers found that by adding a measure of castor oil, which is a vegetable oil made from castor beans, they could achieve the perfect balance. They called the new product ‘Castrol’. The company formally adopted the Castrol name in 1960, and in 2000 it was acquired by bp.

The production of lubricants at the Neuhof site on the southern edge of the Hamburg port area began in 1976. Together with its research and development centre in Shanghai, China, the Castrol DTC in Hamburg-Neuhof is now a global competence centre for Castrol’s gear oils and EV fluids. Highly complex EV lubricant solutions are being developed at the DTC to improve the efficiency of the latest electrified drive systems. Significantly, three out of four of the world’s major vehicle manufacturers now use Castrol ON EV Fluids for factory fill (GlobalData report for top 20 selling OEMs; total new passenger car and light commercial vehicle sales in 2023).

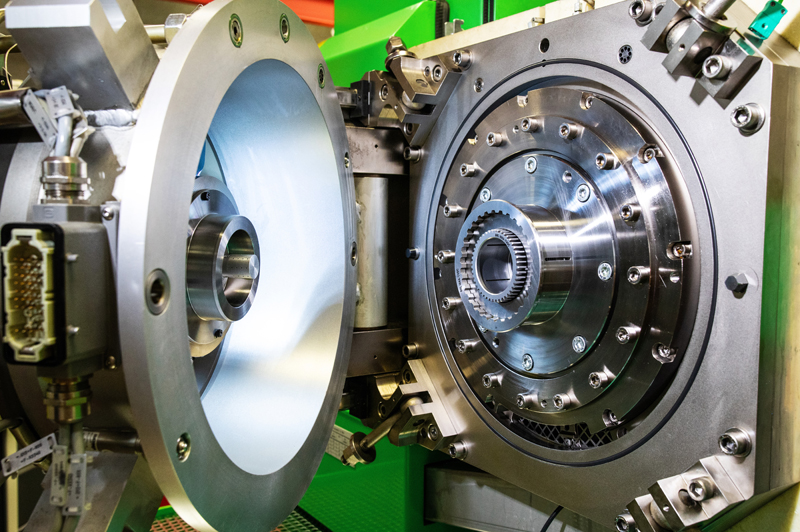

Castrol tests its products at the DTC, continuously making improvements to meet new technical and regulatory requirements. “Our latest EV transmission oils for fully electric vehicles support the development of new powertrain architectures that OEMs create to be more efficient, more compact and more durable,” explains Daniel Knoblauch, expert team leader, advanced electrification OEM liaison.

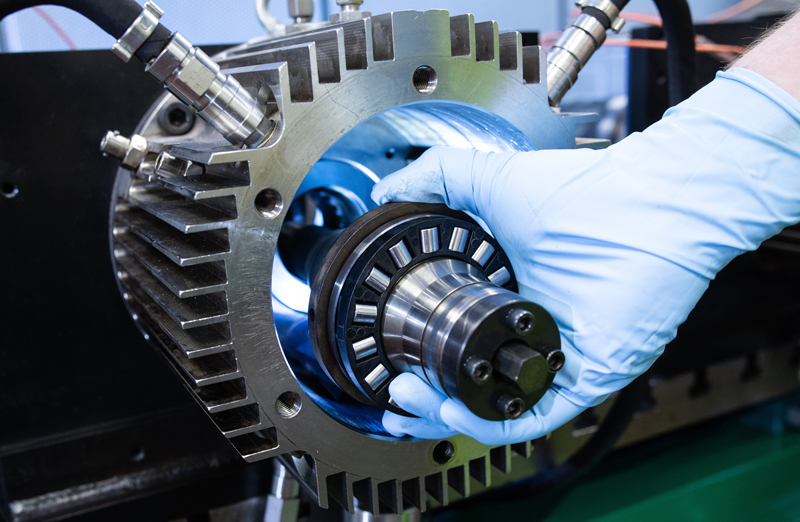

To meet a diverse range of test and development requirements, Castrol teams at the DTC typically operate around 30 ‘test stands’ at any given time: from table-top rigs that evaluate just 40 millilitres of a material, to transmission fluid test stands that fill a large room and can run a full transmission or e-drive unit. After completing test runs that can last from one day to more than a month, tiny differences in efficiency and performance can be measured and the causes and outcomes tracked.

A unique benefit of the Hamburg location is the wealth of experience of local employees, some of whom have been working in research and development for Castrol for decades.

EV transmission fluids

The Castrol ON Dry EV Transmission Fluids, synthetic fluids formulated for transmissions with dry electric motors, are developed at the DTC. The products are part of Castrol ON’s advanced EV product range, which also includes EV thermal management fluids and EV lubricating greases.

The Castrol ON transmission fluids help compatible EVs go further (vs mass market EV factory fill fluids), charge faster (vs indirect cooled battery system) and last longer (vs standard EV transmission fluid). The EV lubricants play an important role in aiding efficiency and extending the life of vehicle components. The lubricating fluids create a balance between reduced fluid viscosity and gear and bearing protection.

Castrol ON EV Wet Transmission Fluids have been developed for powertrains with ‘wet’ electric motors. In addition to low conductivity and high resistance, the new EV fluids fulfil numerous additional requirements, including effective protection against copper corrosion within the electric motor. On top of that, these fluids have excellent cold-flow properties to aid ‘pumpability’ at low operating temperatures, as well as outstanding thermal properties and exceptional oxidative stability. All of these facilitate lower temperatures in the gearbox and motors thanks to significantly reduced friction.

Supporting new plug-in powertrain technologies

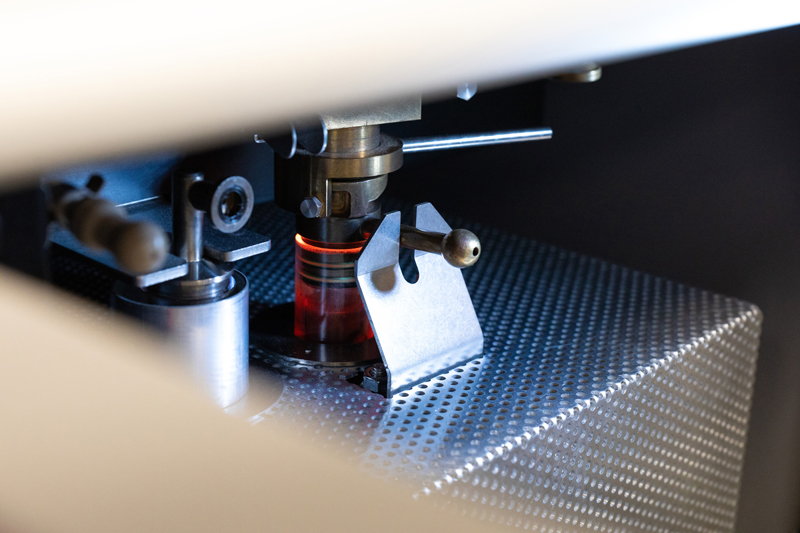

The precise behaviour of a new lubricant cannot entirely be calculated and measured via standard test processes. Where the journey is headed becomes clear in the DTC’s central analytical laboratory with attached special analytics, where employees research the innovations of tomorrow. They come up with several original test fluids per week, which can help shape major changes in mobility.

“While the historical gear oils were thick, odorous and highly viscous, the new generation of EV fluids are characterised by being odourless and significantly thinner,” explains Patrick Bauer, team leader, Thermal Management Fluids. “The water-like EV thermal fluids that are being used in the thermal management system of electric vehicles are even thinner, reducing the temperature of batteries, electric motors and other components in electric drive systems.”

In the analytical laboratory, every innovation begins with a first small blend of only 100 millilitres of a new fluid. At the end of the development, this small amount is the starting point for a scalingup process from the laboratory to full scale multiple thousand litre production runs. Typical test methods that are run at the laboratory include the evaluation of ‘foam behaviour’, testing the electrical properties, and the ‘copper strip test’. The formation of foam must be avoided with lubricants because the liquid could have a reduced cooling capacity and it can also lower lubrication performance.

The electrical properties of fresh oils and used oils must be carefully checked, particularly with EV thermal fluids that could ultimately be introduced into the internals of electric motors and batteries. In the ‘copper strip test’, aging processes are simulated by increasing temperatures.

With microscopes and mass spectrometers further detailed evaluations of the composition and performance of the new product can be done. In addition to providing its Castrol ON EV fluids to OEMs for passenger vehicles, Castrol has been the Official EV Fluids Partner to the Jaguar TCS Racing Formula E Team since 2019. Castrol works with the team to coengineer advanced EV Fluids and lubricants for their all-electric race cars. This enables Castrol to further advance its EV fluid technologies for current and future electric road vehicles.

As more and more electric vehicles come onto the service market, more vehicle manufacturers have asked Castrol to provide their workshop partners with an advanced EV transmission oil to support ongoing repair and maintenance work. Patrick Bauer adds: “While these fluids are considered ‘fill for life’ in some electric vehicles, workshops require a replacement product in the event of a repair. Our DTC facility plays a critical role in the development of those fluids.”