JLM looks at how changing customer behaviour and rising costs are forcing technicians to dig deep.

Motorists are neglecting their cars; hardly a startling statement for any time served technician. Joe Public is delaying servicing or not bothering in the first place; only bringing their vehicle in when it’s ground to a halt, sometimes beyond economic repair. Motorists are also, perilously, heading down the DIY route with cheap-as-chips additives they’ve picked up with the supermarket shop. Close inspection of these products often reveals little or none of the active ingredients required to make good on their promises. This is especially concerning for workshops given the rise in operational costs.

A recent survey conducted by the Motor Ombudsman Bureau validates these statements. Technicians were asked about the challenges facing them.

54 per cent said that customers were putting off essential repairs and neglecting servicing.

49 per cent said customers were also neglecting routine maintenance.

75 per cent said that rising operational costs, taxes and energy bills were the most significant challenges facing them; followed closely by paying more for spare parts – not to mention the regular delays in obtaining them.

It’s a perfect storm that Mike Schlup, MD of Kalimex, the UK distributors of JLM Lubricants’ products, is also familiar with, commenting: “We work closely with top tier technicians throughout the UK, and we meet up with them at trade events. We understand their pain points. We also know from anecdotal feedback and rising sales, that technicians are actively looking to diversify and to build new income streams, as well as streamlining efficiencies; not at the expense of sacrificing customers or alienating their team, I hasten to add! Additives are now on the workshop menu and for compelling reasons. They can sometimes be used as a robust and credible alternative to a part or a repair, especially if the age or condition of a vehicle does not justify the expense. Using an additive can also reduce the time spent on a vehicle and it keeps the customer’s final bill within affordable limits. If a proven, trade trusted, trade tested additive can tick the box, everyone’s a winner. We’re also seeing thousands of technicians using additives to build a growing income stream.

These workshops know that whilst a customer may be putting off workshop visits, if they can sell them several additives to use in between these visits, on the basis they will help keep their vehicle in good working order, then that’s another win.”

Why should technicians choose JLM Lubricants’ products for workshop use, and to promote to their customers? As Mike explains, “JLM focuses on developing and manufacturing products in line with the Lean philosophy, which aims to deliver value to the customer by continuously improving processes and eliminating waste to provide more value with fewer resources. Crucially JLM works closely with technicians to ensure that every product is road tested, professional feedback is considered, and improvements are made swiftly.”

“A top-tier additive with a high active ingredient percentage offers a reliable and affordable alternative for technicians considering customer budgets. These technicians also realise that despite their reminders and marketing messages, some customers will nonetheless fall through the net, only bringing their vehicle for repair as a last resort.”

“These customers should be informed about additives and the benefits of maintaining their vehicle between regular services,” continues Mike. “It’s not a perfect science but for any workshop, additives provide an additional income stream, one that will grow if every team member talks about them to customers and promotes their virtues in reducing repair bills and optimising vehicle health. It’s about making additives a core part of the business culture.”

Oil changes neglected

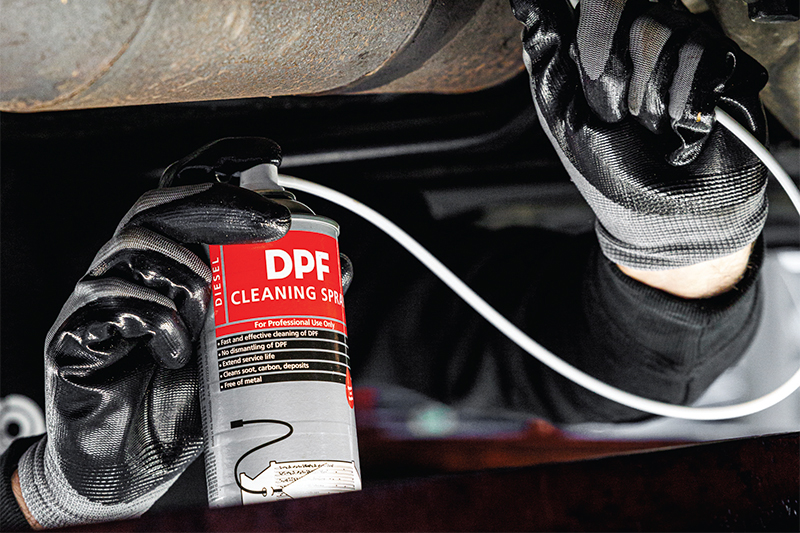

“Technicians are telling us that customer are neglecting oil changes with the inevitable consequence that the oil becomes polluted with sludge deposit accumulations. This increases exhaust emissions and contributes to poor fuel economy,” says Mike. “For diesel vehicles, dirty and deteriorating oil can prevent active DPF regeneration, leading to blockages. The customer can then be faced with an eye watering bill for a new DPF. We recommend that workshops use and recommend the JLM Lubricants’

Engine Oil Flush Pro and the full JLM range of oil treatment products. The JLM DPF range of products, including the trade only professional Diesel DPF Cleaning Toolkit is a must for any workshop that services and repairs diesel vehicles. Your customers can also buy the Diesel Particulate Filter Cleaner, the DPF Diesel Regen Plus and the Diesel Emission Reduction Treatment from their workshop. All of them one step easy to use products.”

“I’ve highlighted some JLM Lubricants’ products for technicians to use and recommend regularly. I would encourage readers of PMM to get in touch,” concludes Mike.