Paul Dobbyn, director of BG Products explains why fuel system cleaners are essential to the running of modern vehicles.

Do additives work? Yes, and they are essential too. The statement (usually not up for debate) we often hear is “additives do not make a difference”. This is an attitude that seems to be rooted in and passed down through the generations of mechanic folklore – without any consideration as to a) Is it true? b) Was it ever true? and c) If the answer to b is correct then is it still true?

It is worth clarifying a point here: Fuel additives have become synonymous with fuel system cleaners. This is where there can be a misunderstanding. Additives can be just chemicals that are added to the fuel to achieve certain goals such as fuel stability, reducing deposits or lowering emissions. A fuel system cleaner containing detergents is something that should do what it says on the tin – clean the fuel system! To have their full effect, additives need to be used consistently as they are designed to improve the quality of the fuel. It’s an important job.

Fuel system cleaners

In this article I want to refer to fuel system cleaners and in particular the ones that can clean hard-baked carbon from the injector tip, the piston crown, the internal workings of the injector and the intake valves.

The Worldwide Fuel Charter, a document signed up to by all engine manufacturers, states the following:

Influence of detergent additives

Cleanliness of the injectors has become a higher priority because

of high pressure injection systems. Modern engines, with their specified performance in terms of power, fuel consumption and emissions over time will depend largely on the cleanliness of their injectors.

Modern engines are using much higher pressure in their injector systems to allow faster fuel delivery as well as smaller droplet size to aid combustion. Deposits on, and in, the injectors interfere with that rapid and atomised fuel delivery and so interfere with (as stated in the charter) “power, fuel economy and emissions” of the vehicle. Indeed, we are seeing new types of deposits inside diesel injectors too caused by a combination of pressure/heat, fuel residue and changes in fuel composition through bio diesel.

Remember, a modern fuel injector will often be only a third of the size of a human hair – so it only requires the smallest of deposits to interfere with the precision and integrity of the fuel delivery.

With that in mind, and appreciating this is the car manufacturers’ own representative body saying this, then really every garage should be including a quality fuel system cleaner at every service (and charging the customer for it), in the same way that a garage would not think twice about changing an oil filter or a fuel filter (and passing on that cost).

Interestingly, research from 2018 suggests that 82 per cent of drivers are happy to know about services/treatments that are good for the car or save them money.

Quality fuel system cleaners, used periodically, will keep the critically important injectors free of power-sapping, emissions-increasing, fuel-wasting deposits.

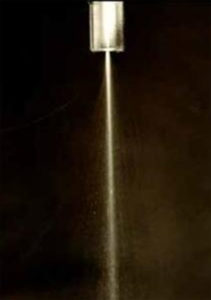

The question now becomes, ‘do fuel system cleaners clean deposits?’ We can only speak for the results that BG Products produce but in the pictures here you can see before and after pictures of spray patterns.

Figs.1&2 show spray apertures from a diesel engine before treatment and 1,000 miles later. There is a significant reduction in the deposit around the hole.

In the injectors shown there is a clear difference in the quality of atomisation.

The positive impact of keeping injectors clean is not just lower emissions and better fuel economy, there is also a positive impact on components such as EGRs, DPFs and Turbos. This is a consequence of better fuel atomisation allows more efficient combustion and in turn that means less soot production.

A quality fuel system cleaner is vital for garage customers and will pay for itself though fuel economy alone, plus it will forestall other issues.