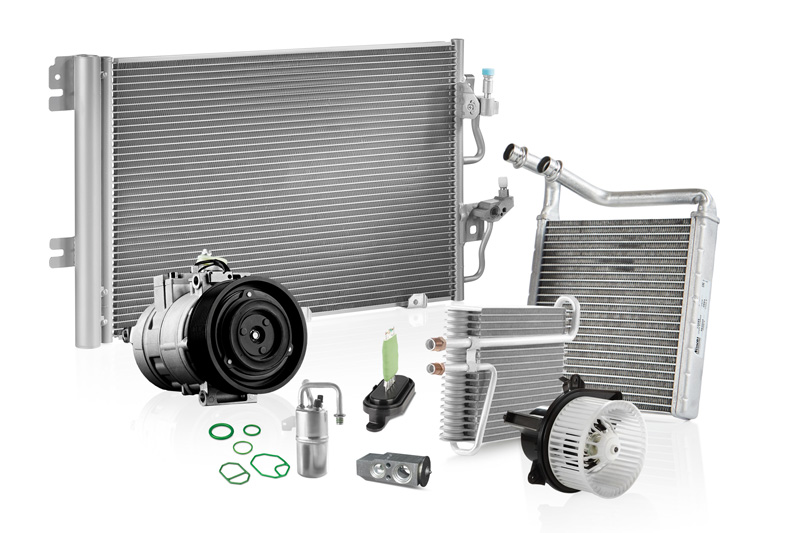

AVA, part of the Nissens Group, is explaining how its A/C parts range is designed to simplify tasks for the workshop technician.

Among the seasonal tasks facing the typical workshop is the service and repair of air conditioning systems, as owners find they have problems when they switch on and expect a rush of cool, fresh air, only to be greeted with a lukewarm and stale smelling one!

Obviously, to maintain a going concern, workshops need to have a broad range of skills and knowledge to service and repair the vehicles that they take in. However, partly due to its traditional seasonality, which means it’s not a daily job, and also due to its inherent complexity, working on an A/C system can often be a significant challenge.

Fortunately, workshops are not left to flounder as AVA, part of the Nissens Group, is on hand with its Clever Fit concept, which makes life simpler for the technicians undertaking the work, and its optimised range of quality replacement components also takes away some of the complications when it comes to multiple part numbers.

Fixing problems

Expanding on the Clever Fit concept, AVA has directly addressed one of the primary irritations for those that actually have to fit replacement parts, namely to have at hand all of the related items they need by way of fixings such as nuts, bolts, washers, clips and screws and consumables like O-rings and other seals etc., as these are all including in a single box.

On top of the convenience it gives to technicians, which allows them to complete the installation as easily as possible, it is also a big benefit to workshops as it speeds the fitting process, which in turn maximises efficiency and the number of jobs it can carry out each day.

While providing a cost effective, but high quality replacement parts solution, and facilitating a hassle free installation are major benefits, as a thermal management specialist, AVA is also able to help by sharing its knowledge when it comes to technical matters.

Although an A/C system comprises many important components, the condenser is one of the most critical as it maintains the correct performance parameters of the refrigerant and keeps the overall system working properly. It therefore needs to be regularly and carefully checked.

The condenser is relatively fragile, and its position at the front of the vehicle exposes it to harsh conditions, such as de-icing salts used in the winter, which can quickly lead to corrosion, causing the condenser’s surface to deteriorate and leak. Furthermore, mechanical damage from careless service, insects or dust, and other debris from the road, can limit the condenser’s heat exchange performance.

Even if the part seems to be okay and is still partially working, a condenser in poor condition can lead to costly system failure, such as damage to, or even complete seizure of, the compressor, for example. That is why it is advisable to perform condenser inspection during regular car and A/C system service.

Overall, condenser failures are relatively common, therefore its impact on the efficiency of the system should not be ignored. Any signs of damage or substandard performance require diagnosis to determine the root cause and, if a replacement is required, it is important to fit only a product of the appropriate quality, as this will secure long and optimised system performance and help to avoid repeat repairs.

Although its range is enhanced to provide multiple solutions across a limited number of parts, the quality of AVA’s components is beyond reproach, which means alongside the benefits of workshop efficiency, those installing its replacement parts can relax in the knowledge that they are fitting a product that delivers performance and reliability.