Replacing brake fluid may not be a part of your standard servicing package, but it’s still something which needs to kept on top of. Here, febi explains how the unique properties of brake fluid allow the vehicle to remain safe and when and why that fluid needs to be replaced.

It is well known that servicing and maintaining a vehicle will prolong its efficiency, performance and safety – thus increasing its lifespan. Consequently, vehicle manufacturers create recommended maintenance schedules for each model, which can vary from market to market based on environmental conditions and other factors, such as if the vehicle is used for towing or taxi work.

Safety checks are carried out on the vehicle’s steering, suspension and braking systems, and common service replacement items include engine oil and oil, air, fuel and cabin filters. Fluids that are not replaced regularly, such as brake fluid, may be considered as optional. A vehicle’s brake discs and pads may receive regular checks, but the condition of the brake fluid receives less attention.

Hygroscopic properties

Brake fluid is hygroscopic, which means it likes to absorb moisture. This can be a problem because higher moisture content leads to a lower boiling point – therefore, the older the brake fluid, the less effective it is.

Brake fluid is an important safety-critical component within a vehicle’s braking system. febi DOT 4, DOT 4 LV (low viscosity), DOT 4 Plus, DOT 5.1 and DOT 5.1 EHV (electric and hybrid vehicle) are fully-synthetic brake fluids based on glycols, containing oxidation and corrosion inhibitors. They can also prevent vapour bubble formation and have improved dry and wet boiling point properties.

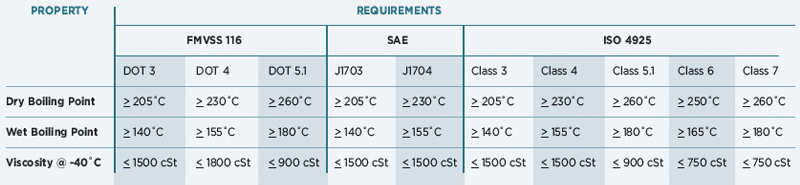

Friction during the braking process generates heat; some of this heat is absorbed by the brake fluid, which must meet the requirements defined in the applicable standards:

- Dry boiling point of the brake fluid with no water content [°C]

- Wet boiling point of the brake fluid with water content [°C]

- pH value of the brake fluid

The parameters are defined by standards FMVSS No. 116, SAE J1703, ISO 4925 and PN-EN ISO 2719: 2016-08 and constitute some of the basic criteria for determining the suitability for use. These parameters are summarised according to standards SAE J1703 and ISO 4925 (dry and wet boiling points, viscosity), as well as FMVSS No. 116 (pH value), in the table show in Fig.1.

The importance of replacement The boiling point of a brake fluid is a temperature at which gas bubbles form. As soon as gas bubbles form, the pressure in the brake system can no longer be maintained because the gas can be compressed. The consequence is a sudden reduction in braking effectiveness, which can lead to an accident.

The hygroscopic property of brake fluid is required so that any water present distributes itself evenly throughout the liquid. If water is collected in a specific area, the boiling point would lower to approximately 100°C. However, if the water is dissolved in the brake fluid up to a proportion of 3 per cent, for example, the boiling point would remain significantly higher than 100°C, where the risk of bubble formation is much lower.

Several factors affect and accelerate the absorption of water. These include the storage of brake fluid in open, unsealed packaging for longer periods, non-compliance with brake fluid service intervals, damaged brake system components (e.g. cracks or splits in the outer layers of flexible brake hoses), or damaged seals/gaskets. The hygroscopic properties of the brake fluid stem from the glycol content. This allows the fluid to gradually absorb more and more water, which also means that it needs to be changed on a regular basis. Vehicle manufacturers generally recommend changing the brake fluid every 30,000 to 50,000 kilometres or every two years, subject to operating conditions.

Without regular maintenance, the high moisture content held within the brake fluid corrodes the internal metal components of the brake system, contributing to seizing brake calipers, failing anti-lock brake modulators and the deterioration of the internal brake hose rubber, causing blockages within the braking system.

Electric and hybrid requirements

Electric and hybrid vehicles are becoming more popular. Therefore, febi has added an enhanced brake fluid specifically for the requirements of EHVs. In technical terms, when a vehicle’s battery is full, the brake system cannot take advantage of regenerative braking. Therefore, the brakes must do all the work without any support from the engine or electric motor braking. This creates the need for a brake fluid with a higher dry and wet boiling point – typically 274°C and 184°C respectively – as well as increased lubricity and viscosity.

In normal conditions, the brakes are used less because of the proportion of work done by regenerative braking. However, they must still be in perfect working condition when required. This creates the need for enhanced corrosion protection, due to the high electrical currents in the vicinity of the braking system, and a lower conductivity fluid.

To ensure an effectively-functioning braking system while guaranteeing driving safety in all road traffic conditions, brake fluid must be regularly checked and replaced as necessary. febi brake fluids are developed in accordance with the binding quality standards and requirements of vehicle and brake system manufacturers to meet all requirements for current brake systems, including electronically-controlled brake systems which need to perform reliably within fractions of a second.