As a critical item on the MOT tester’s checklist, KYB recommends that every vehicle that comes into the workshop during (and after) the winter months is checked for broken coil springs as a matter of course.

The majority of drivers will not even realise when they have a broken spring on their vehicle.

Rapid corrosion

During harsh weather conditions, any road spring can ultimately break. Grit thrown up from the road hits the coil springs and can damage the surface coating. This means that the metal becomes exposed and it therefore rapidly corrodes, especially when there is salt on the roads. In addition to this, debris which collects on the spring pan acts as a grinding paste between the spring and spring seat.

Even though a coil spring may appear to be in perfect condition when viewed in-situ with the shock absorber, the coil which is in contact with the shock absorber itself may have suffered from extensive corrosion, making it liable to breakage at any time.

The ongoing trend to reduce the shape and size of coil springs versus the continuing increase in vehicle weight is also a contributing factor to the increase in coil spring breakages. Drivers demand more optional extras, such as air conditioning and sound systems – but this additional weight puts more strain on the spring. High strength steels have been introduced, which are capable of working at higher stress levels, however even with a good surface coating on the spring, the harsh conditions on the roads in the winter mean that they are still susceptible at this time of year.

What if the spring needs replacing?

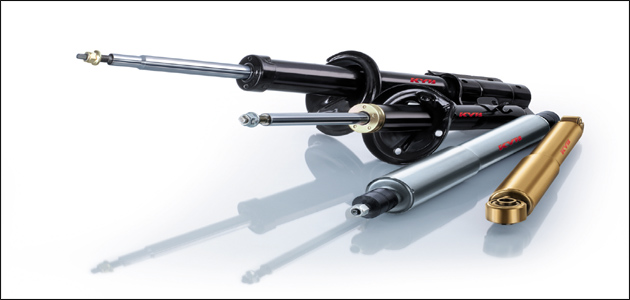

If the inspection of the coil spring highlights a breakage, resulting in a replacement being required, why not take the opportunity to check the shock absorber, suspension mounting kit and protection kit at the same time?

Shock absorber and coil spring manufacturers always talk about the importance of fitting shocks and springs in pairs – the reason for this being that shock absorbers wear gradually over time. If one is  identified as leaking and worn, it’s most likely that the other one is too, as there is no significant difference between the wear rates on each side. However, if oil isn’t pouring out, the second one is not recommended for replacement. If a shock is worn, it is no longer keeping the tyre in contact with the road – which is dangerous. It also leaves the car imbalanced.

identified as leaking and worn, it’s most likely that the other one is too, as there is no significant difference between the wear rates on each side. However, if oil isn’t pouring out, the second one is not recommended for replacement. If a shock is worn, it is no longer keeping the tyre in contact with the road – which is dangerous. It also leaves the car imbalanced.

Coil springs should be replaced at the same time as this in order to maintain an even ride height on the vehicle. They also return the vehicle to the correct ride height, as they can become coil-bound over time – this is essentially losing their ‘bounce back-ability’.

The most effective way for the vehicle owner to understand this issue when it comes to their vehicle service is to explain to them the importance of fitting a pair. To help back this up, manufacturers all have a range of point of sale material – such as posters and leaflets – that garages can use in their MOT viewing area or reception.