Contitech provides readers of PMM with some background advice for working on belt-in-oil drive systems.

With belt-in-oil technology, the timing belt for driving the timing gear runs in its own oil bath. The key benefit here is the reduction in frictional losses, which is also reflected in the vehicle’s fuel consumption and CO2 emissions. Belts in oil also run much more quietly than a chain drive, for example. Besides increasing driving comfort, the belt’s smooth operation also has a positive effect on the oil’s useful life in the vehicle.

We initially developed our timing belts for belt-in-oil technology for the Ford 1.0l Eco Boost engine and the 1.2l units from PSA and Opel manufactured from late 2012.

They have been specially geared to the specific demands of operation in oil. Another application is the Ford 2.0l EcoBlue unit, while Volkswagen 1.6 and 2.0 TDI engines also use a timing belt in oil for driving the oil pump.

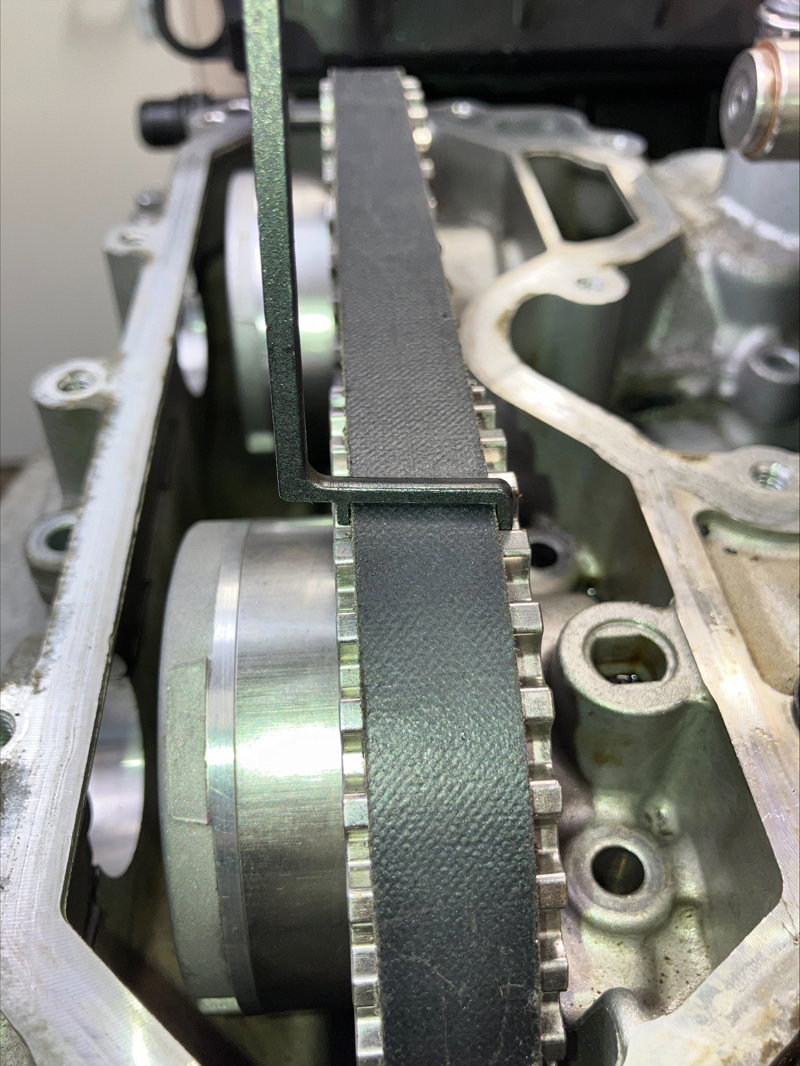

There is a risk of soot building up in modern direct injection engines with high compression ratios. These soot particles can become lodged in the oil bath between the sprocket and the belt, damaging the belt and thereby ultimately causing damage to the engine. Other crystalline compounds or fuel in the oil (dilution of the oil) also pose a challenge for the belt. Our timing belts are able to withstand these strains thanks to their special material composition (Fig.1).

The right oil

Oil is one of the most important operating fluids in a car. It is therefore crucial to follow each manufacturer’s exact specifications and only use approved oils when changing the oil. Here, mechanics need to check the oil’s technical properties as well as its grade. This is particularly true of vehicles with belt-in-oil technology. These require special oils whose chemical composition has been tailored specifically to the particular engine application. Additives can also be used to reduce the formation of soot referred to above. These include dispersing agents, friction modifiers, corrosion inhibitors, antioxidants and cleaning agents.

Over time, the aforementioned additives become less effective at preventing soot formation. The reason for this is the oil in the engine becoming diluted over the course of operation. This is a normal phenomenon (within certain limits) that occurs less in vehicles used for long journeys and more in vehicles that either drive short distances in urban traffic or operate as taxis/delivery vehicles with frequent engine starts and stationary periods.

On short journeys, a particularly high quantity of fuel accumulates in the engine oil, where it then impairs the belt. Leaving a vehicle that is only used for short journeys parked up for a prolonged period can therefore do far more harm to the belt than driving it daily. The duration of contact with the diluted oil is largely responsible for the damage caused to the belt. Driving with a full load, towing a trailer or frequently driving uphill can also speed up dilution of the engine oil.

Other factors that can lead to faster engine oil dilution include:

- Use of an oil that does not match the specifications of the oil recommended by the manufacturer.

- Failing to follow maintenance intervals.

- Use of additional additives that harm the composition of the engine oil.

- Not maintaining the engine oil at the correct level.

When the engine is used under aggravated operating conditions, servicing work such as oil changes and vehicle inspections need to be carried out sooner. Because diluted or fuel-contaminated oil also has an abrasive effect on timing belts in belt-in-oil engines, the timing belt may also need to be replaced more frequently if necessary. As a general rule, oil changes for belt-in-oil engines should be carried out every 20,000 kilometres and at least once a year. Ultimately, though, the manufacturer’s specifications should always be followed here.

Detecting damage caused by the wrong oil

Timing belt damage is a continuous process that begins slowly. First, the back of the belt starts to crack (Fig.2), as can be observed on PSA and Opel engines by simply looking through the oil cap (Fig.3).

As wear increases, individual fibres or teeth break away from the belt and are deposited in the strainer upstream from the oil pump.

In the case of 1.2l PureTech engines from PSA and Opel, the strainers for the variable camshaft timing system’s two solenoid valves can also become clogged with belt particles, as can the vacuum pump’s oil strainer. This can also lead to faults in the oil pressure system (oil pressure warning lamp).

The timing belt on 1.2l PureTech engines from PSA and Opel must be checked annually during every oil service using a control gauge. The control gauge must fit over the back of the belt. If the timing belt is damaged, it will swell and become larger, meaning that it needs to be replaced (Fig.4).

If the timing belt has to be replaced due to the belt disintegrating, it is advisable to carry out additional servicing work:

- Check and clean the two solenoid valves for the camshaft timing; replace if necessary.

- Check and clean the vacuum pump’s oil strainer; replace if necessary.

- Check and clean the oil pump’s strainer.

- Replace the banjo bolt for the turbocharger’s oil feed.

- Change oil and replace oil filters.

- Check and clean the oil pressure control valve, replace if necessary.

If the oil is heavily contaminated, impurities may accumulate in the oil strainers again after traveling a short distance (Fig.5), whereupon the additional work must be repeated until all impurities have been removed. This does not necessarily mean the timing belt will have to be replaced again, however.

What to do if the wrong engine oil is used?

If a non-approved oil is ever added to the engine by mistake, the wrong oil should be drained immediately and replaced with an engine oil that has been approved by the vehicle manufacturer. If the customer has driven the vehicle with the wrong engine oil for some time, the timing belt may have already suffered damage. Draining the wrong oil and topping up the engine with an engine oil that has been approved by the vehicle manufacturer might still be sufficient. It is advisable, however, to carry out another oil change after a short period of operation. If the timing belt has already been damaged, particles would once again be deposited in the oil strainers leading to the fault messages described above. In addition to this, the timing belt width should also be checked with the control gauge on PSA and Opel engines.