Nissens Automotive discusses its turbo offering to the automotive aftermarket.

Despite the rise in the number of electric vehicles, turbocharged internal combustion engines remain dominant in the service and repair sector. In fact, industry forecasts project a 10 per cent plus growth in the turbocharger market by 2030, with the independent aftermarket expected to account for more than 50 per cent of the replacements, within a decade. Driving the growing demand are stricter emissions regulations, the prevalence of downsized engines and the increasing complexity of turbocharging technologies.

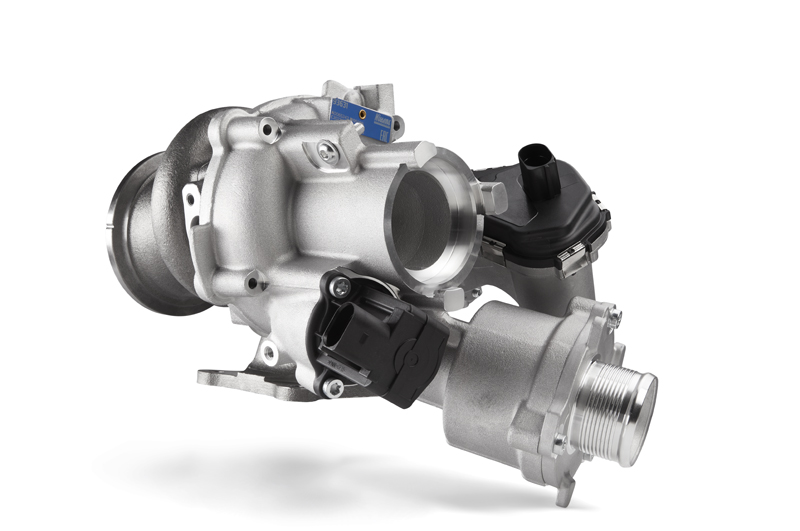

In this vibrant market, Nissens Automotive has positioned itself as a leading provider of premium aftermarket turbochargers. The company offers a reliable, high coverage solution designed to meet the needs of independent workshops, and the distributors that supply them. Over the past seven years, Nissens has refined its turbo programme through rigorous research and development, field testing, and strategic commercial planning, ensuring a product that delivers performance, durability, and ease of installation.

Ease of installation

For workshops and the technicians undertaking turbocharger replacement, technical support and ease of installation are key considerations, as these factors provide them with extra confidence and help them to carry out a full and thorough repair.

As a result, another ingredient within the complete Nissens offering is recognition of the critical role of technical support in the successful installation and maintenance of turbochargers. The company therefore provides a comprehensive range of technical support services, including a dedicated turbo hotline, e-learning modules, live learning sessions and technical marketing materials. These resources are designed to equip professional technicians with the knowledge and confidence necessary for proficient turbo installation, maintenance, and troubleshooting.

Furthermore, the Nissens First Fit concept ensures that all the essential installation parts, such as gaskets, stretch bolts, and a syringe enabling the pre-lubrication of the turbo shaft, are included in the product box. Other critical installation parts, like oil feed lines, are fully available in the programme to aid efficient turbo installation and ensure their long-term reliability.

All Nissens turbos are new units, manufactured from quality materials, which eliminates the need to return the old unit or pay the surcharge, a requirement that is typical with many remanufactured components. In addition, each is safeguarded by robust packaging to ensure their maximum protection both on the shelf and in transit.

As a result, the installation process is made seamless, allowing technicians to achieve a successful installation on the first attempt, which is the most cost-effective solution for the workshop and its customers.

Development

Nissens takes a distinctive approach to developing its aftermarket turbos. This process involves significant investment in research and development, meticulous testing, and thorough field examinations. By leveraging in house expertise and collaborating with external institutes, Nissens ensures that its turbos meet the highest standards for performance, reliability, and durability. The result is a product that not only matches, but often exceeds the qualities of the original turbo, earning the prestigious Genuine Nissens Quality stamp, a guarantee of reliability throughout the engine’s lifespan. Furthermore, Nissens remains a leader in aftermarket parts innovation by using high quality materials in many of its turbo models to ensure compatibility with modern, highperformance engines.

For instance, turbos designed for engines that operate under extreme combustion temperatures due to stringent emissions requirements and lean combustion for enhanced fuel economy utilise advanced, heat-resistant alloys such as D5S and 1.4848. Additionally, some Nissens truck turbo models feature highly durable titanium compressor wheels, while high-end engine turbos are equipped with advanced electronic actuators.

Technical advice

Among many technical tips and advice, is this example concerning the 1.6-litre PSA DV6 diesel engine, used in many applications, which providing it is serviced correctly and in accordance with the vehicle manufacturer’s schedule, is a solid and reliable unit. It is however, particularly vulnerable to lubrication related issues if regular maintenance is ignored, or subjected to incomplete service where the oil filter has not been replaced.

Although turbo failure will naturally require its replacement, simply carrying out an oil and filter change and replacing the turbo, without finding the underlying cause, risks further turbo failure. So, in addition to highlighting the issue and providing the insight to allow workshops to complete a full and thorough repair, Nissens has four replacement turbo kits (two basic and two with additional parts, designated plus) for the various models of this engine.

As mentioned, although oil degradation and contamination are generally the root cause of these turbo failures, a related issue is oil flow. The two problems are closely linked as the contaminated oil can block or restrict the lubrication channels and oil lines, disrupting the flow with carbon or soot deposits, or sludge that has built up in the oil.

Three other frequent causes of turbo failure on this engine are: DPF regeneration failure, often caused by a build up in back pressure because of restrictions in the filter, foreign objects in the air intake/exhaust system and leakage in the air intake system, which can cause turbo over speeding. Both the basic and plus versions of the kits are available for both DPF and non-DPF variants of the DV6 engine, with the basic kits (Nissens part numbers 9300908 and 9300909) containing the oil pick up/strainer, oil feed line, oil return line, oil return line flange and two banjo fitting bolts, whereas the plus kits (9300910 and 9300911) also come with two oil filters, plus their assembly gaskets, as well as vacuum pump and oil cooler gaskets.

These four kits, plus the two replacement turbos (93037 and 93061), combine to provide workshops with a reliable repair solution that is straightforward to install and matches the performance of the original unit.

Feedback

Workshops and distributors across Europe have been applauding the Nissens turbo programme. The positive feedback concerning reliability, ease of installation and competitive pricing underscores the company’s commitment to delivering high quality products that meet the needs of the aftermarket.

As the demand for turbocharged engines continues to grow, Nissens stands ready to meet the challenges of the evolving market, ensuring that aftermarket professionals have the products, technical insight and support they need to succeed.