Two trusted PMM reviewers put two Sealey tools through their paces.

Tom Godfrey the VS8230 borescope

A borescope is becoming more and more of a must-have tool in today’s modern workshops. Often only used to inspect cylinder bores the cameras are being used for much more fault finding in today’s environment. I reviewed the Sealey VS8230 and first impressions are fantastic, the camera comes in a hard plastic moulded case to ensure it stays damage free when not in use. Packed with accessories such as the 9mm camera probe, camera charger, 45° mirror, hook, magnetic pick-up, AV and USB cable and most importantly a 4GB micro-SD. The camera has a 3.7 V lithiumion rechargeable battery which takes six hours maximum charge time which in turn gives you up to 4.5 hours of video record time and up to 10,000 images.

The borescope has screen resolution of 320×240 pixels which provides a clear crisp picture on the 85mm colour screen. I love the fact that you can adjust the LED brightness on the end of the probe as well as zoom in and out and rotate/flip the images. It feels great when holding and is easy to navigate through its menu when in use. Pictures and videos are saved by one click of a button which is easily transferred to a computer or an external monitor using the RCA cable included. The 9mm probe has a 1m length to it which is great for getting down the back of engines, dashboards, inside door cards and into exhaust systems. The probe itself provides a great viewing angle of 53°.

We will often grab the borescope on a daily basis in our workshop especially when servicing vehicles as it can be difficult to see components such as the bottom of rear coil springs when sat in the rear trailing arms. Not only is it great for us to see but any broken springs we may find the picture is easily transferred to a computer and attached to the vehicle’s health check for the customer to see. Another case was a BMW X5 with a heavy engine oil leak. The leak itself was running down the side of the engine which was impossible to see from the top with the airbox and exhaust system in the way and underneath as engine covers, shields, and components such as the air conditioning compressor in the way. With the Sealey borescope we could easily manoeuvre around these items and quickly establish the cause of the oil leak.

Issues with diesel particulate filters are helped diagnosed with borescopes where on occasions it can be difficult to remove the system a camera can be used through temp sensor holes to assess the condition, looking out for any defects such as cracks of even missing internals.

Mirror image

Sealey has thought of everything when it comes down the VS8230, the 45° mirror is great when inspecting engine cylinder bores, not only can we inspect the top of the piston and the cylinder bores, but we can also attach the mirror to inspect the bottom of the intake and exhaust valves. Capturing a video rather than multiple images is a bonus as we can keep looking back and go over our findings in case we missed something the first time. In the unfortunate case of dropping a bolt and it falls in a tight spot between the engine block and starter motor for example, the camera helps not only find the bolt but when used with the magnetic pick-up it becomes a must for time saving.

In today’s environment where it’s even more important to find and record all your findings the Sealey VS8230 in my opinion is a must for any workshop. Not only a great tool for diagnosing faults and time saving, it’s another great tool for building the trust with our customers.

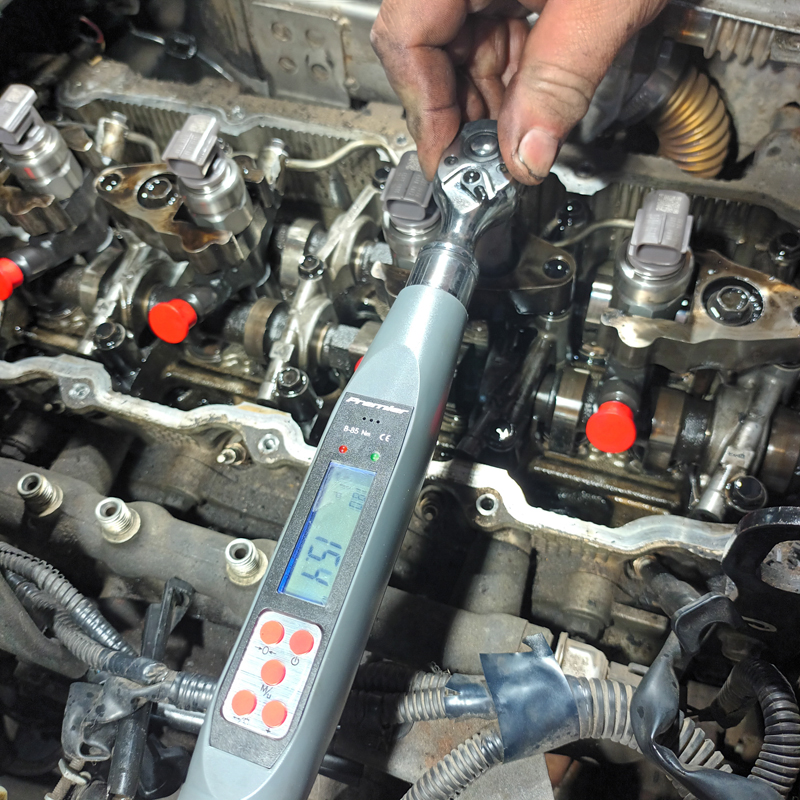

Tony Powell 3/8 IN. digital torque wrench, model No. STW 308

The wrench arrived in a glossy cardboard sleeve which waxed lyrical about the tool’s capabilities. Beneath this flashy exterior lay the sturdy black-blown plastic case which held the torque wrench itself. Opening the case revealed a very nicelooking wrench with a shiny chrome reversible ratchet head and a very comfortable feeling grey plastic handle.

As with many tools I was initially disappointed due to the lack of batteries, but this disappointment soon proved misplaced, as on further inspection I found them hiding under the paperwork in the bottom of the case. Paperwork, it should be noted, which included a relevant calibration certificate.

Installing the batteries was simple and quick, you just unscrew the base and pop them in, a quick press of the red button and the wrench sprung into life.

Initially setting the wrench without reading the instructions as most of us seem to do was very simple and I was also very pleased to note that once set, the wrench remembered the setting for next time: a good time saver for me as I do hundreds of bolts with the same settings and having to set and unset each time becomes quite a bind (winding off the tension on the spring on my mechanical torque wrench reduces wear and keeps it in calibration for much longer). Not a problem with a digital wrench though. Once I read the instructions I found that it can actually remember several different torque settings even when turned off and back on, most useful if using the same settings repeatedly. This particular wrench operates from 8 to 85 newton-metres but can also read in lb.in, lb.ft, or kgf.m. I should add here that wrenches with higher limits are available in the same range.

Once set, the wrench will vibrate and emit an audible alarm once the preset-limit is reached and the scale has an LCD readout with LED backlight. I also noticed that at a simple flick of a switch on the ratchet head the wrench can be used to discover how tight bolts are when undoing them or when using a left-hand thread, of course.

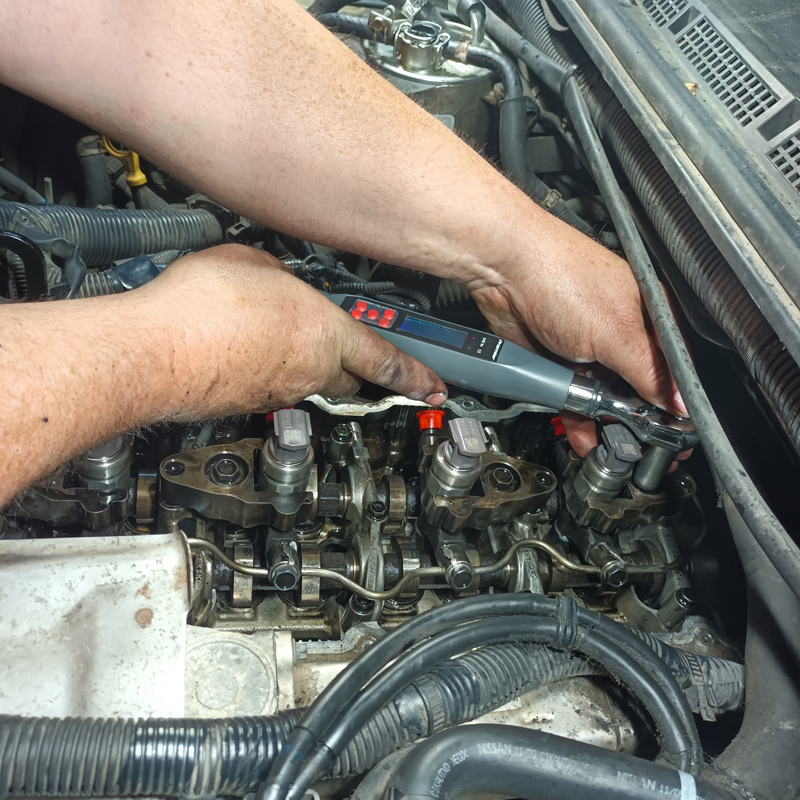

This size wrench is ideally suited to smaller nuts and bolts as found in many vehicles these days including the likes of spark plugs, which need to be torque-tightened to ensure they are located in the correct orientation to ensure an efficient burn of the fuel mixture, injector clamping bolts and use on lawnmowers and motorbikes etc. With a length of 34 cm or just over 13 inches and a good solid feel it looks and feels the part.

Sealey has covered all the bases by using a vibrate, audible beep and a warning light when the set limit is approached and met. So if you’re working in a loud environment you still know the limit is reached. I’ll admit that a part of me does miss the old-fashioned clunk made by mechanical wrenches and in my opinion, the beep could be louder!

In use, the wrench has proven to be a very helpful tool saving me quite a bit of time in winding on and off to release the spring pressure as I have to do with my old wrench.

The wrench itself is comfortable to use and although solid feeling, it’s not too heavy and doesn’t cause any fatigue in use. Plus, it’s small enough for use in the engine bay without difficulty.

The verdict?

Certainly a very nice, easily operated and useful tool and well worth the prices I’ve seen quoted for it.