How can such a small part play such a big role in a vehicle’s handling? Well, Polybush explains.

When it comes to vehicle suspension, the smallest components often have the biggest impact. Suspension bushes, although relatively simple parts, play a crucial role in maintaining the ride comfort, handling, and overall safety of a vehicle. For years, mechanics have wrestled with the limitations of traditional rubber bushes— leading to frustrated customers and repeat repairs.

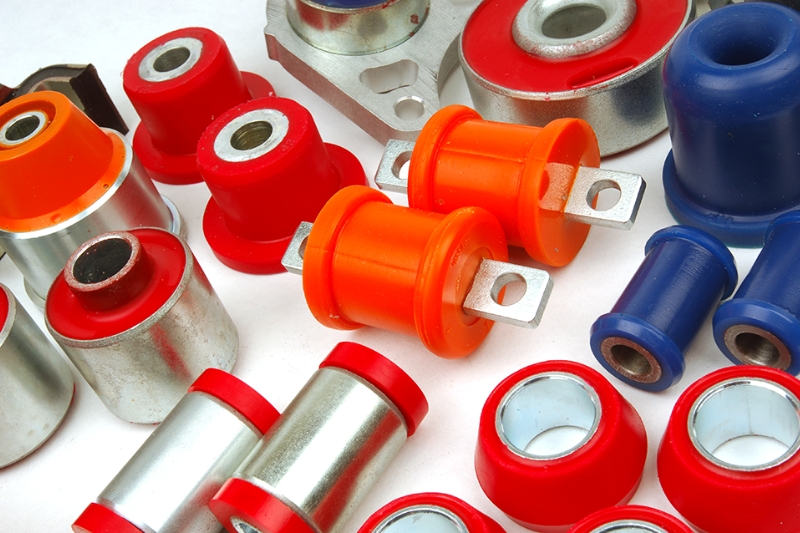

Polyurethane suspension bushes, like those produced by Polybush, represent a smarter, longer-lasting solution. In this article, we’ll explore why traditional rubber bushes fail, why polyurethane outperforms them and how Polybush bushes save mechanics time and effort in the workshop.

Rubber rubbing up the wrong way

Rubber has been the go-to material for suspension bushes since the earliest days of the automobile. Its initial flexibility allows it to dampen vibrations and noise effectively, but it comes with a significant drawback: Rubber degrades over time (which can be as short as six months)

Several factors contribute to this failure:

- Environmental damage: Rubber bushes are highly vulnerable to exposure to oil, fuel, road grime, salt, and extreme temperatures. These elements cause the rubber to dry out, crack, or swell, leading to premature wear.

- Compression set: Rubber bushes soften and deform with repeated compression, which occurs every time the vehicle is driven. This results in excess movement, leading to uneven tyre wear, vague steering, and a less responsive driving experience.

- Short lifespan: On modern and performance vehicles, rubber bushes often need replacing after as little as a few thousand miles. For mechanics, this means frequent customer returns for bush replacements – often resulting in frustration and complaints.

Polyurethane alternative

Polyurethane, the material Polybush uses, addresses all the shortcomings of rubber and provides several unique advantages:

- Superior Durability: Polyurethane is immune to oil, grease, UV, and weather conditions and is far more resistant to deflection than rubber. Polybush bushes have been proven to last over 10 times longer than traditional rubber bushes, with some lasting hundreds of thousands of miles.

- Better handling performance: Unlike rubber, polyurethane doesn’t suffer from significant compression set or deformation. This stability ensures consistent handling, improved steering response, and reduced tyre wear—factors that are especially crucial for performance vehicles and workhorses like vans and 4x4s.

- Retains comfort: For classic cars and Land Rovers, we offer a choice of bush hardness to suit different needs, from comfort to performance. On modern vehicles, we engineer bushes to exceed factory specifications, providing durability and a slightly sportier ride while maintaining compatibility with the vehicle’s suspension system.

- Reduced maintenance: While rubber bushes crack or disintegrate within a few years, Polybush products continue to perform for decades, reducing the need for replacements and callbacks.

Easier to install

One of the standout features of Polybush bushes is how much easier they are to fit compared to other aftermarket options. For mechanics, this means saving valuable time and avoiding headaches.

- No special tools required: Polybush bushes are designed to be installed with basic workshop tools, unlike other products that require hydraulic presses or specialised equipment. This is particularly beneficial for mobile mechanics or smaller workshops.

- Split design for easy fitting: Many Polybush bushes are designed as two-piece units, which makes installation far quicker than trying to wrestle a single, solid bush into place.

- Pre-lubricated design: Polybush bushes come with a specially formulated polyurethane which is slightly oily, this ensures smooth installation and prevents squeaking once installed.

- Direct replacement fit: Polybush bushes are precision-engineered to fit into existing mounts without modifications. Whether working on a classic restoration or a modern performance car, you can trust that the bushes will fit perfectly every time.

Proven performance

Mechanics are often sceptical of new materials or designs, but Polybush products have a long track record of success in the real world:

- Classic cars: Owners of classics like the MG BGT or Triumph TR6 trust Polybush to provide a lasting solution for worn-out suspension components, with options tailored for comfort or performance.

- Performance cars: For models like the Audi TT MK1 Quattro or MX-5 ND, Polybush products enhance handling while retaining drivability.

- Workhorse vehicles: Vans such as the Ford Transit and 4x4s like the Land Rover Defender benefit from the exceptional longevity and robustness of polyurethane, even under the harshest conditions.

Customers value the enhanced driving experience and reliability that Polybush bushes provide—and as a mechanic, it’s always satisfying to fit a product that delivers real value and eliminates repeat repairs.

It’s how they’re made

- ISO9001 Accredited: Every Polybush product is manufactured to the highest standards of quality, ensuring consistent performance and fitment.

- Made in Britain: Designed and produced in the UK, Polybush bushes are created with the specific needs of British roads— and their challenges—in mind.

- Comprehensive range: Polybush offers bushes for over 40 car marques, including Abarth, Alfa Romeo, Ford, Jaguar, Land Rover, Mazda, and many more. Whether your customers drive classics, modern vehicles, or high-performance models, there’s a solution available.

- Environmentally friendly: Polybush products last significantly longer than rubber bushes, reducing waste and contributing to a more sustainable automotive industry.