Blue Print guides PMM readers through clutch systems and how its Smartfit clutch conversion kits can facilitate clutch repair for independent workshops.

A vehicle’s clutch is the primary system that transfers the engine output to the gearbox, which must be optimally synchronised in all driving conditions. The clutch separates and connects the vehicle’s engine to and from the transmission. When the clutch pedal is depressed, the vehicle’s powertrain is interrupted and a different gear can be selected. The clutch also enables the vehicle to accelerate away smoothly and efficiently.

Vehicle development has evolved and adapted in a variety of ways, this has directly influenced how all the working components of the vehicle have developed. This includes a vehicle’s clutch components, which must satisfy a host of requirements and have a direct effect on the driver’s comfort and the behaviour of the vehicle.

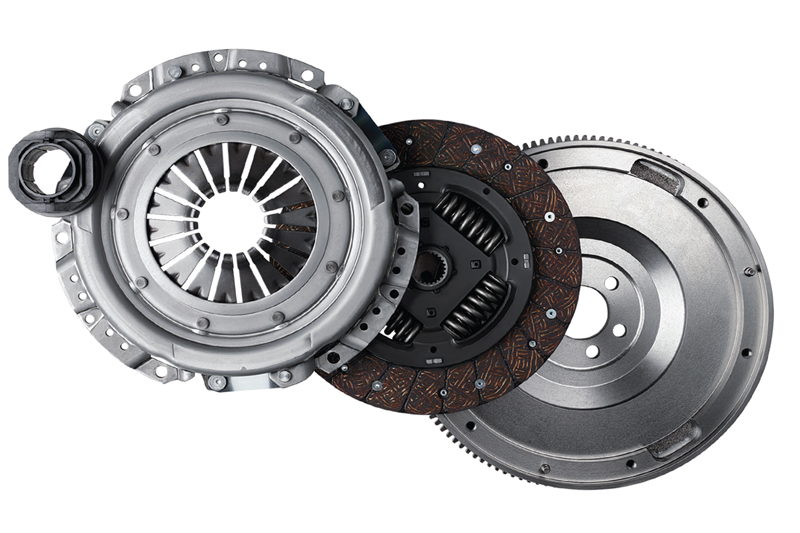

These include an increased engine torque, stop-start, demand for smooth and quick gear selection and reduction of noise, vibration and harshness characteristics, including damping and noise reduction. A clutch must have good resistance to rotational speed, low overall height, low engagement forces and provide a long service life, to give high transmission reliability. The main clutch components are the clutch cover, friction disc and release bearing. Together they form a friction system with the flywheel.

Clutch cover

The clutch cover ensures that the engine torque is transferred smoothly via the friction disc to the transmission intake shaft. Slotted diaphragm springs are used in the pressure plate to increase driver comfort, because it requires less effort to apply pressure on the pedal, due to the lower engaging force. Depending on clutch design, structure and actuation, these are either a push or pull type pressure plate, to compress the diaphragm spring.

Friction disc

The friction disc is the clutch kit’s central connection component, in combination with the clutch cover, it both separates and connects the engine and transmission. Each clutch disc lining is selected to the particular vehicle application, to enable smooth torque build-up when pulling away. They also reduce the speed and torque fluctuations, generated by the internal combustion processes of the engine. The clutch disc must also provide the damping function, in order to reduce noise and stress in the gearbox.

This can be provided by a clutch disc fitted with a torsion damper, which is a solution for overcoming torsion fluctuation problems in the powertrain and guarantees a precise damping function, even when the engine is idling.

Clutch release bearing

The clutch release bearing, forms the link between the rotating diaphragm spring, in the clutch cover on the engine side, and the release mechanism on the transmission side, which slides on the guide sleeve mounted in the gearbox bell housing, as it is operated. This gives the bearing a central position in relation to the diaphragm spring tips of the clutch, which is achieved at all times. Self-aligning reduces the wear on the diaphragm spring fingers, and thereby counterbalances a possible misalignment between engine and transmission. Release bearings are either mechanically or hydraulically operated, via the clutch fork or are of a concentric slave cylinder type, which consists of a ring-shaped hydraulic cylinder, with a built-in release bearing.

Smartfit system

When replacing this important vehicle component, which transmits the engine’s power to the transmission and absorbs the stress and vibration of constant operation, it is crucial that high quality components are used. Blue Print claims its Smartfit system is a tailor-made solution for a professional and cost-effective repair.

In order to meet the exact demands of each vehicle’s requirements, all clutch components undergo stringent quality control tests, with the aid of automated measurement tools, all product dimensions are checked to be accurate to the thousandth of a millimetre.

Dual-mass flywheel kits

The Smartfit for dual mass-flywheel type clutches is a coordinated combination of a rigid flywheel and clutch disc, with torsion damper guaranteeing, excellent vibration damping and with the customary high degree of driving comfort. In order to protect the gearbox, torsion dampers, tuned specifically to the engine, are used in the Smartfit kit. The torsional vibrations generated by the engine are filtered out in all driving conditions, noise is reduced and the service life of the clutch is prolonged by means of low-wear clutch linings. No special tools are required for these retrofitting kits to provide a quick, professional conversion. New fixing bolts, high-performance grease and specialist installation instructions are enclosed to ensure a straightforward replacement.

Blue Print also supplies these kits without the flywheel. The enormous benefit, is that the previously installed rigid flywheel can be re-used when the clutch is replaced. This means that only the clutch disc, pressure plate and release bearing need to be exchanged.

Self-adjusting clutch kits

The advantages of these Smartfit kits include quick and easy fitment, because conventional clutch covers are used and no special tools are required to install them. Therefore, there is no need to secure the clutch pressure plate without applying a counterforce. This not only significantly reduces the time required, but also the risk of incorrect installation.