99.9% of A/C compressor issues aren’t a result of product failure as Nick Thomas, DENSO Aftermarket UK Product Manager, discusses

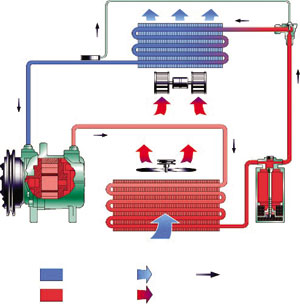

Compressors are vital to a vehicle’s A/C system; compressing the low temperature, low pressure gaseous refrigerant from the evaporator, into a high temperature, high pressure gaseous refrigerant, and discharging it to the condenser.

Compressors are vital to a vehicle’s A/C system; compressing the low temperature, low pressure gaseous refrigerant from the evaporator, into a high temperature, high pressure gaseous refrigerant, and discharging it to the condenser.

Oil in the A/C system is essential, primarily to lubricate moving parts, i.e. the compressor and the expansion valve needle. It also enables heat to escape from the compressor. As with refrigerant, oil in the A/C system must retain its chemical stability.

However, it is vital to choose the right oil for the job. Insufficient lubrication due to universal oil is the second most frequent reason for A/C compressor damage and failure. Analysis of our warranty claims for 2012 showed that in 24% of cases, garages did not use the correct PAG-oil needed for DENSO A/C compressors.

What are the pitfalls of universal oil?

The use of incorrect oils, such as universal oils or oil mixtures, inevitably leads to A/C compressor damage. This is because universal oils, often preferred by garages, are PAO-oils, or mineral oils with a different viscosity than synthetic PAG-oils. The difference between these two types of oil means that they do not mix, leading to poor lubrication, damaged seals and increased wear.

If the oil is diluted, the lubricant base layer decreases. This results in the piston rubbing against the cylinder bearing surface. If the oil is too thick, it is unable to ‘squeeze’ between the cylinder and the piston.

If the oil is diluted, the lubricant base layer decreases. This results in the piston rubbing against the cylinder bearing surface. If the oil is too thick, it is unable to ‘squeeze’ between the cylinder and the piston.

DENSO’s First Time Fit® A/C compressors have a tight tolerance between the cylinder and piston of only 3 μm. A change in the oil viscosity can result in more frictional resistance, leading to an increase in compressor temperature and subsequent seizure.

Blending or mixing of different types of oils may lead to the formation of paraffin. This can block the flow of the refrigerant and oil, leading to seizure of the compressor and system failure.

Quantity as important as quality We would also advise that it is not only the quality, but also the quantity of oil in the system that is of great importance. Too little oil leads to poor lubrication of the compressor, rising component temperature and oil scorching on the suction side of the compressor. Too much oil in the system will increase the load on the piston-crank system, which can lead to a block in the body of the thrust bearing and the hard front piston co-pivotable skid plate.

We would also advise that it is not only the quality, but also the quantity of oil in the system that is of great importance. Too little oil leads to poor lubrication of the compressor, rising component temperature and oil scorching on the suction side of the compressor. Too much oil in the system will increase the load on the piston-crank system, which can lead to a block in the body of the thrust bearing and the hard front piston co-pivotable skid plate.

Is the oil filtered?

It is also essential that any solid impurities in the compressor oil are removed in the filter-dryer.

The filter-dryer will also capture moisture from the oil. As part of the annual maintenance of the A/C system we recommend that the filter-dryer is changed, but it is equally vital to remove a proportion of the oil, replacing it with the same quantity of fresh oil.

DENSO recommends

To ensure the longevity of your compressor, our advice to technicians is to refer to the type label and only charge the compressor with refrigerator oil that is of the specified quality and viscosity.