PMM speaks to Steve Beynon of FLIR Systems, to find out more about the increasing use of thermal imaging technology in the automotive world.

Although thermal imaging has always been an appropriate technology for motor mechanics, cost has been an inhibiting factor. In recent years, however, the entry level cost has steadily fallen and the technology continually developed to provide a wide choice of affordable devices. As a result, thermal imaging is increasingly being used in vehicle workshops.

The choice of device essentially depends on the job, whether you simply want to confirm temperature or investigate a wider problem. All thermal imaging instruments work on the same principle: they are noncontact devices that detect infrared radiation and translate it into a temperature reading.

Horses for courses

Even a spot thermometer can be considered a thermal camera with just one pixel and is very useful for a wide variety of tasks. However, it is still simply a tool that measures temperature in one spot, nothing else. Sitting between a spot thermometer and a thermal imaging camera is an imaging thermometer, a new breed of instrument that combines the two for fast troubleshooting. It provides a non-contact temperature reading while the thermal imaging mode will show the relative thermal properties of a subject or targeted area in the context of its surroundings.

Needless to say, an imaging thermometer doesn’t have the sophistication of a dedicated thermal camera but it allows you to see heat patterns, measure temperature accurately and store measurement data for reporting. And for many, the introduction of thermal imaging via a simple low-cost device such as this is a springboard to doing more with the technology.

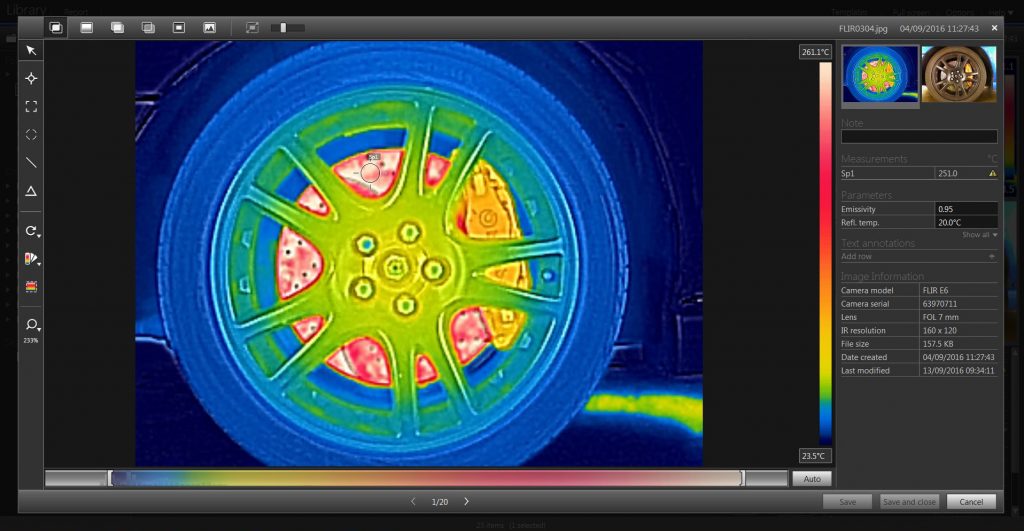

The next step up is a basic troubleshooting camera which is often a surprisingly sophisticated tool, despite its relatively low cost. The choice of types is now wide, from pocket portable and torch-style models to smartphones with imaging capability, but you should pay close attention to detection resolution. A thermal imaging camera generates an image from multiple pixels, each of which provides a temperature reading. In effect, the camera combines thousands of spot thermometers in one device. So a camera with an image resolution of 160 by 120 pixels, such as the FLIR E40, is therefore able to provide 19,200 temperature readings at once.

Higher resolution infrared cameras can measure smaller targets from farther away and create sharper thermal images, both of which add up to more precise and reliable measurements. Therefore, if you want to be able to use a thermal imaging camera for the widest possible range of workshop tasks, buy the model with the highest resolution detector that your budget will allow.

What are the applications?

Thermal imaging, in whatever form you choose, will provide valuable information to assist in the diagnosis of a problem. It allows you to ‘see’ blockages in exhaust systems or radiators, spot hotspots caused by mechanical misalignment, a misfiring cylinder or electrical connection issues. It’s also ideal for checking the efficiency of heated seats or air conditioning systems. The application potential of this technology in the workshop is huge.

FLIR TG167

FLIR has recently introduced the FLIR TG167, a cost-effective imaging thermometer. This is a new breed of instrument that combines spot temperature measurement with thermal imaging for fast troubleshooting.

The FLIR TG167 provides a non-contact temperature reading while its thermal mode shows the relative thermal properties of the problem in the context of its surroundings. So, it’s ideal for spotting mechanical misalignment, a misfiring cylinder or electrical connection issues, diagnosing blockages in exhausts or radiators and checking the efficiency of heated seats. And, of course, it can also be used for straight temperature measurement applications such as the air outlet of an air conditioning system.

Another big benefit of the FLIR TG167 over a straight spot thermometer is that it saves images and data that can be used to give customers proof of a problem. You can also download images via USB or a removable 8GB micro SD, both of which are supplied as part of the kit, for inclusion in reports. The narrow field of view lens on the FLIR TG167 – 25 degrees horizontal – is ideal for vehicle inspection. It provides quality image detail with a 24:1 spot size ratio that also enables you to work at a safe distance away from the potential problem.

What’s made this all possible is FLIR Systems’ development of the Lepton micro longwave thermal detector which is the size of a smart phone SIM card. In the FLIR TG167, this is combined with another new technology, called Infrared Guided Measurement (IGM), which guides you to hot and cold spots that are invisible to the naked eye.