PMM has enlisted technician, Darren Cotton, to attend the full range of course modules on the Bosch Diagnostic Technician Programme over the coming months. On his most recent visit to the training centre in Uxbridge, Darren undertook module VSG 5: Engine Management: Diagnosis of Universal Components.

This module covered the skills and knowledge required to test and diagnose engine management systems, including the components within those systems. The two-day module involved a combination of classroom theory and practical tasks in the workshop. Automotive diagnostic testers, digital multimeters and oscilloscope devices were all used in the session and I would recommend that delegates are competent in using these pieces of equipment before attending. The skills required to operate these pieces of equipment are helpfully covered in other Bosch courses.

The day started with the training facilitator providing an overview and explaining the operation of some early Motronic systems. It was important and relevant to cover this history as this was a giant step forward in automotive technology, enabling electronic control of both fuelling and ignition in one Electronic Control Unit (ECU). This introduction provided the delegates with an understanding of the engine management system and how it has evolved into its current iteration in modern day vehicles.

My highlight of this section was covering fuel sub systems. We looked at the inside of components such as fuel pumps, using regulation to control the pressure. We also looked at how the system was controlled in earlier vehicles, in comparison to today’s modern returnless fuel systems. We then discussed fuel flow testing in modern returnless systems.

In the practical task, the delegates were split into two group, with each group given a test rig. Following ESI[tronic] test instruction and specifications, we were able to complete fuel pressure tests and create different conditions, analysing the effects it has on the engine management system. We discussed the tests and results back in the classroom.

Next, the trainer explained how to get the best results from the Bosch diagnostic equipment by using a diagnostic concept and process from initial diagnosis to the final fix. The training facilitator went through the basic functions of an Engine Control Unit, making sure that each delegate understood volt drop and was capable of carrying out the four tests on a circuit. This is also covered in more detail in Bosch course VSE1 – Essential Test Procedures.

A workshop practical task was then set. Each rig was set with a fault to simulate a real-life situation, and the delegates were split into groups, working together with a diagnostic plan using KTS 590 and the technical information within ESI[Tronic]. After agreeing our circuit tests, we executed our plan using an oscilloscope and a digital multimeter. The fault was soon identified. Another task was set and we worked together using the skills we discussed in the classroom.

My main highlight of this module was the section on sensors. This covered the various inputs on an ECU, rotational speed, temperature, engine load and ignition. The internal operation of passive, voltage modifying, and active sensors were all explained, as well as how and why they give an input signal and how we should test them. Going through these types of sensors and being able to identify them on a wiring diagram made this easier to understand.

The output signals of the different types of sensors were also explained as we discussed each one. The trainer made sure each delegate understood digital and analogue outputs for the type of sensors discussed. This led on to actuators for fuel delivery, idle control and charge control – again the internals, operation and output signals for the actuators were explained in detail. We also covered frequency, duty cycle and pulse width modulation.

In addition, we were given various practical tests related to sensor testing on the test rigs, whilst staying in our groups, and we measured and tested all the sensors the trainer taught us about in the classroom. The two days finished with content covering emission control, secondary air system, catalyst, lambda sensors wideband and zirconia, exhaust gas recirculation and tank vent systems.

Conclusion

This module is well worth doing. Understanding the operation will help you diagnose a faulty component correctly and efficiently. As ever, the course was delivered in a very professional manner and at a good pace. The trainer answered any questions given by the delegates and made sure they understood. As always, the facilities were excellent, the Bosch staff were friendly and the atmosphere was relaxed.

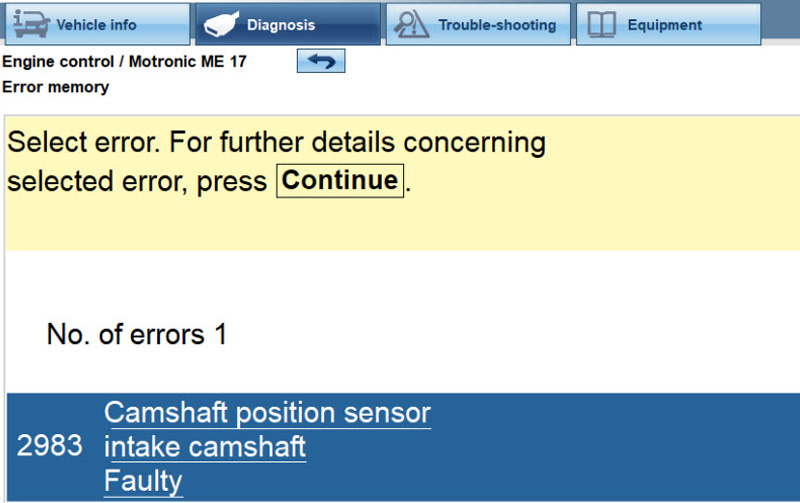

As luck would have it, after finishing the course, I had the perfect chance to put this skill set to the test, as I was presented with a 2009 BMW MINI with an Engine Management Light on. Using the KTS590, we retrieved the fault code displayed in Fig 1.

Using the troubleshooting in ESI[Tronic], I gained access to the circuitry of the inlet camshaft sensor. Testing and confirming with the oscilloscope supply to the sensor (cavity 1) and the ground (cavity 3) were in good order. The signal output (cavity 2), however, was flatlined. After checking that the mechanical pick up on the camshaft was OK, the diagnosis was confirmed to be a faulty camshaft sensor. Once the sensor was replaced, the output signal was checked and confirmed as a fix.