Our over-worked wire wrangler Ben Johnson gets hit with a boomerang BMW – and with his speedos already packed for his holiday, it’s truly a race against the clock to get it up and running again…

Every now and then, a case comes along that fries your brain so thoroughly that you find yourself contemplating the unthinkable: reaching out to BMW technical support. Even as a seasoned dealership fault finder, I rarely needed to take such a step. But let me take you through this particular ordeal with a G01, a vehicle that some of you who follow me on social media may recall. I had discussed installing a Schottky diode to a LIN power distribution box to prevent back feeding from the DME, which had resulted in a permanent fault on the distribution box in the rear of the vehicle. That solution, however, turned out to be nothing more than a temporary fix—one that addressed only 50 per cent of the problems with this car. In this article, I’ll delve into the main issue and reveal how sometimes the obvious can be staring you right in the face, yet can still remain irritatingly overlooked.

The saga began with a G01 that mysteriously lost battery voltage every 40 miles or so. With over a hundred fault codes logged, it was like playing the Spanish lottery to decide where to even begin the fault-finding process. For those familiar with BMW, you’ll know that their fault descriptions often make little sense, a byproduct of a company whose engineers speak a different first language. BMW, in its infinite wisdom, has a knack for overcomplicating even the simplest issues, and they are masters of misusing the English language.

Take the term “global undervoltage,” for instance. One would assume that “global” implies something affecting the entire system. According to the Oxford English Dictionary, “global” means “relating to or encompassing the whole of something, or of a group of things.” So why, if one component has an issue, is this described as a “global” problem? If your head isn’t already spinning, welcome to the world of BMW fault finding. It’s a maze you get used to navigating over the decades.

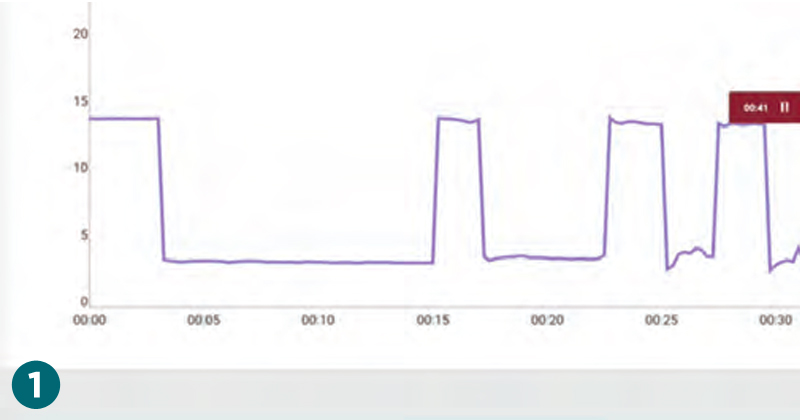

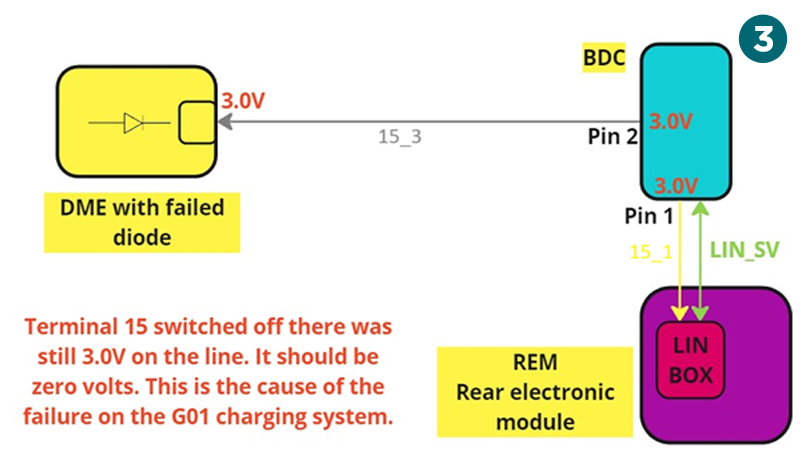

Returning to the story, I zeroed in on a LIN box, particularly the line 80406D: “LIN power distribution box: Short circuit/line disconnection of emergency operation line (15_1)” fault code. Why focus here? Simple – after each key off/on cycle, every fault code would clear, except this one. That stubborn code suggested an issue, and after some head-scratching, I discovered that the reason it wouldn’t clear was due to a rogue voltage hanging around with the key off. Instead of dropping to zero, it lingered at a choppy 2-3 volts. By disconnecting this yellow wire, I confirmed that the voltage was coming from the BDC. Even with the line disconnected, the LIN power distribution box still threw a fault code because it lacked a power supply on the backup line. However, I had pinpointed the BDC as the source of the unusual voltage (Figs.1&2).

Before we delve into this further let me explain what the LIN power distribution box actually is. Put simply the BDC – body domain controller signals this box via a LIN line (LIN_SV) which then switches the various relays in the rear fuse box. The rear fuse box has no microprocessor and only contains fuses and relays. The LIN box is a seriously important piece of hardware¬ which, when removed, will cause the car to seriously have a bad day. I have included a simple diagram in Fig.3 to enable the reader to understand a bit more about how the system works.

To solidify my theory, I compared live data from another G01. On the test vehicle, the voltage smoothly dropped to zero. Now, the question was, what on earth was causing this voltage anomaly?

By sheer luck, I noticed that adjacent to the 15_1 line was another called 15_3, which was actually a power supply line to the DME from the BDC (Fig.4). And wouldn’t you know it, this line also had the same 2-3 volts with the key off. Disconnecting this line from the BDC erased the fault code I had been chasing. But of course, I couldn’t leave the DME without power, so I started pulling DME modules one by one, hoping to find a short in one of the components connected to each module— components such as the accelerator pedal position sensor, throttle position sensor, or valvetronic motor.

The first module I disconnected was the culprit, instantly killing the key-off voltage. But with the clock ticking and the customer needing their car back, my only viable option was to try a diode on the 15_1 line to block the back feeding voltage that I suspected was at the root of all these issues.

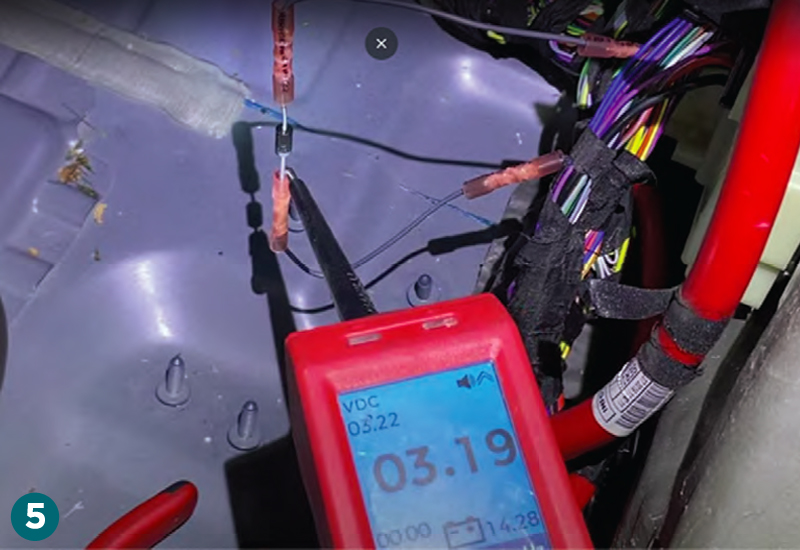

A standard diode wouldn’t do; it causes a significant voltage drop, which would reduce the 14V when the car is powered up down to around 4V—a 10V drop is far too much. Enter the Schottky diode. This 70-cent marvel is known for its minimal voltage drop, so I picked a few up from Partco. The voltage drop was indeed minimal, around 0.6V, leaving me with 13.7V after the diode and crucially, 0.0V of back feed—magic! I had seemingly solved the issue, with no more fault codes (Fig.5). Or so I thought…

The customer drove off happily, but within a day or two, the car was back to its old tricks, displaying the same aggravating “global undervoltage” fault code. It was a Thursday morning, and I had been given the entire day to resolve the issue. No pressure, right? Especially with my month-long summer holiday starting the next day. I have to be honest—I was running out of ideas. BMW tech support had ignored my request for help, which was unusual, leaving me completely on my own. Feeling the pressure, I did what I always advise others when they’re stuck: I took a break, grabbed a coffee, and started over from the beginning, just like they do on that show, Air Crash Investigation.

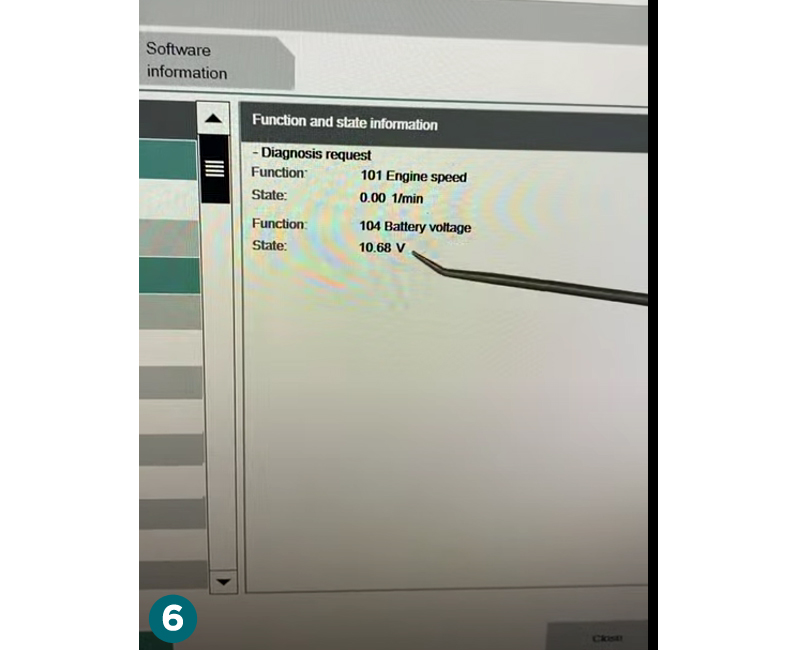

It was during this pause for reflection that I noticed what had been staring me in the face all along, despite the hundred fault codes. The live data in the DME showed 10.5V—undervoltage—while the rest of the car displayed 14.4V. So, the DC-DC converter was fine, but why was the DME voltage so low? A quick check with a power probe showed good voltage powering the DME, around 14 volts, but the ground had a 4.4V drop—clearly a bad ground (Fig.6).

When I applied a ground with the PP Maestro, the DME supply voltage shot up to 14.4V. That was it—just a bad ground. But the location of the ground point, at the back of the engine, made it impossible to see or even feel for, especially on this hybrid with the B48 motor.

Using my newly acquired scope with a motorised head, I managed to get a look at this well-hidden ground, and bingo! It was corroded and had clearly been arcing. The loose bolt was the problem, but with one day left before my holiday, removing the gearbox and all the hybrid components attached to it was not an option (Fig.7).

In such situations, it’s tempting to say “sod it,” cut the three offending ground wires, and run new ones to a more convenient ground point. But doing so would mean losing the ground for the HV AC compressor and the turbocharger cooling pump. Running new grounds to these components would be a massive pain, so I decided to strip back the three grounds and add four new thick supplementary grounds instead. That should do the trick without the need to rewire the other components individually.

I found a convenient ground point at the front of the engine and crafted a neat, factory-looking ground loom, complete with Lucar rings. The best part of this nightmare saga? Not only did the ground voltage return to zero, but the back feeding voltage to the Schottky diode also dropped to zero. It turned out that the whole issue was caused by a production line oversight—not exactly confidence-inspiring!